Ptfe Coated Fiberglass Fabric - Heat Resistant and Fireproof Silica Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: High silica glass fibre fabric is made by silica fiberglass fabric which is a kind of inorganic fiber contaiting more than 96% SiO2. It is high temperature resistance. Its softening point approaches 1700°C and can be used at 1000°C for a long time. It can work short-term at 1500°C. Silica fabric is applicable for use as a high temperature resistant, heat resistant, fire resistant,and corrosion resistant material.It is widely used in avaiation and aerospace, metallurgy, chemical, building material and fire fighting industry. Apart from applications requiring high temperature-resistance, it is also has insulation and fire prevention uses. Such as Thermal insulation covers, padding, lagging, welding blanket, fire curtain and other heavy duty fire control system. Silica glass fibre cloth is suitable for coating with difference elastomers and polymers.

Features: high temperature resistance,heat resistance,chemical resistance

Application: fire doors, fire curtain, welding blanket, fire blanket,heat shielding, removable insulation jackets, cover, mattress, pad,oil, gas, chemical, energy, cement industry,other fire control systems.

PRICE: USD7.5 per square meter

UNIT: square meter

MOQ: 500square meters

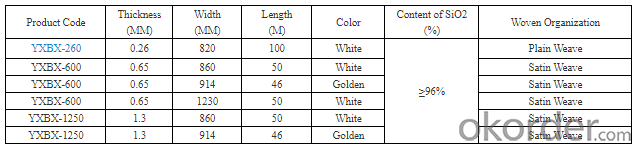

Weight: 430gsm 610gsm 1100gsm 1200gsm

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 1000℃

Product name: Silica Fabric

Coating/Finish/Surface Treatment: Silica

Roll length: 50 meter or customized

Color: white, golden

Weave Type: twill woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.6mm, 1.1mm, 1.3mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: High silica glass fibre fabric cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for making insulation gaskets?

- Indeed, insulation gaskets can be crafted using fiberglass fabric. Renowned for its remarkable thermal insulation qualities, fiberglass fabric is widely utilized in diverse thermal insulation applications. Its capacity to resist high temperatures and conduct heat at a low rate render it an optimal substance for producing gaskets that adeptly seal and insulate against heat transfer. Furthermore, fiberglass fabric exhibits durability, lightweightness, and flexibility, thereby facilitating its handling and enabling its compatibility with various gasket designs. Its chemical resistance and commendable electrical insulation properties further bolster its appropriateness for insulation gaskets.

- Q: What are the different fiberglass fabric coatings for chemical resistance?

- The market offers various fiberglass fabric coatings, each with excellent chemical resistance. Some commonly utilized coatings include: 1. PVC Coating: PVC coating exhibits favorable chemical resistance to acids, alkalis, and solvents. It finds widespread use in applications necessitating protection against corrosive chemicals. 2. PU Coating: PU coating boasts exceptional resistance to abrasion, chemicals, and oils. It is frequently employed in applications where the fabric must endure harsh chemical environments. 3. Fluoropolymer Coating: Fluoropolymer coatings, like PTFE and FEP, provide outstanding chemical resistance to corrosive chemicals, acids, and solvents. These coatings find extensive usage in industries such as chemical processing, pharmaceuticals, and food processing. 4. Silicone Coating: Silicone coating offers commendable resistance to chemicals, oils, and extreme temperatures. It is commonly utilized in applications requiring both chemical resistance and high-temperature resistance. 5. Neoprene Coating: Neoprene coating delivers excellent resistance to a wide array of chemicals, oils, and solvents. It is frequently employed in applications where the fabric must withstand exposure to aggressive chemicals. It is crucial to consider the specific chemical environment and the desired level of resistance when selecting a coating. Consulting a technical expert or coating manufacturer is recommended to identify the most suitable fiberglass fabric coating for a particular chemical resistance application.

- Q: What are the different fiberglass fabric finishes for UV resistance?

- Some of the different fiberglass fabric finishes for UV resistance include acrylic coatings, silicone coatings, and fluoropolymer coatings. These finishes help protect the fiberglass fabric from the damaging effects of UV rays and prolong its lifespan.

- Q: Can fiberglass fabric be used for insulation in oil and gas facilities?

- Yes, fiberglass fabric can be used for insulation in oil and gas facilities. Fiberglass fabric is a commonly used material for insulation due to its excellent thermal properties, resistance to high temperatures, and its ability to withstand harsh environments. It is non-combustible and can effectively prevent heat transfer, making it suitable for insulating pipes, tanks, and equipment in oil and gas facilities. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it a practical choice for insulation in these facilities.

- Q: Is high strength fiberglass cloth the same as high silica fiberglass cloth?

- The high silica glass fiber cloth is one of the high strength fiber cloth, but it is also the most common and most common one.

- Q: Are fiberglass fabrics resistant to UV degradation when exposed to outdoor sunlight?

- Yes, fiberglass fabrics are generally resistant to UV degradation when exposed to outdoor sunlight. The fiberglass material is inherently UV resistant and does not easily degrade or deteriorate when exposed to sunlight. This makes fiberglass fabrics a reliable choice for outdoor applications where UV exposure is a concern.

- Q: Is fiberglass fabric resistant to tears and punctures?

- Fiberglass fabric is widely recognized for its exceptional ability to withstand tears and punctures. This can be attributed to the strength and durability of fiberglass, which is derived from delicate glass fibers. These fibers are intricately interwoven to produce a fabric that exhibits remarkable resistance against tearing and puncturing. Moreover, manufacturers often apply specialized coatings or finishes to fiberglass fabric, thus augmenting its tear and puncture resistance. Nevertheless, it is crucial to acknowledge that the precise degree of resistance may fluctuate based on the particular construction and caliber of the fiberglass fabric.

- Q: How to deal with the high temperature fiberglass cloth, so that the trimming can not be scattered

- Stick it with cellophane tape and it won't break in the scissors.

- Q: Can fiberglass fabric be used for insulation in storage tanks?

- Fiberglass fabric is indeed suitable for insulation in storage tanks. Its remarkable thermal properties make it an optimal selection for insulation purposes. With its low thermal conductivity, it effectively diminishes heat transfer and maintains the desired temperature of the storage tank contents. Moreover, fiberglass fabric offers the advantages of being lightweight, flexible, and easy to install, rendering it a convenient alternative for insulating storage tanks of diverse sizes and shapes. Additionally, it possesses resistance against moisture, chemicals, and UV radiation, guaranteeing its durability and long lifespan. All in all, fiberglass fabric stands as a trustworthy and effective option for insulating storage tanks.

- Q: Can fiberglass fabric be used for banners and signs?

- Certainly! Banners and signs can indeed make use of fiberglass fabric. This versatile material provides numerous advantages in this regard. Its durability, lightweight nature, and resistance to various weather conditions render it fitting for both indoor and outdoor purposes. Furthermore, fiberglass fabric boasts a sleek surface that allows for top-notch printing and vivid colors. It also proves effortless to maneuver and can be readily mounted or hung. Ultimately, employing fiberglass fabric for banners and signs guarantees prolonged lifespan and aesthetic allure, explaining why countless businesses and organizations favor it.

Send your message to us

Ptfe Coated Fiberglass Fabric - Heat Resistant and Fireproof Silica Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords