Heat Resistant PTFE Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: PTFE coated fiberglass fabric is fiberglass cloth coated with Polytetrafluoroethylene on the surface to meet customer demands. It offers excellent features such as anti-static, fireproof, heat resistance, corrosion resistance, chemical resistance, waterproof, non-adhesiveness, low coefficient of friction, high tensile strength. PTFE coated fiberglass fabric is compliant for use in high temperature insulation, removable covers and blankets, pipe insulation, food processing, packaging, and handling.Features: fireproof, heat resistance, corrosion resistance, waterproof, anti-static

Application: thermal insulation jacket, high temperature insulation, removable covers and blankets, pipe insulation

PRICE: USD6 per square meter

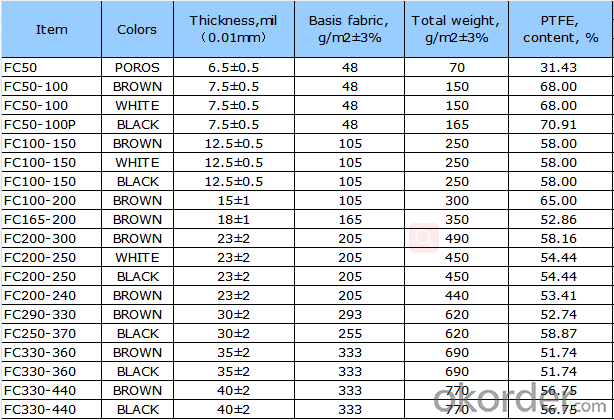

Weight: 400gsm-800gsm

Width: 1m, 1.2m 1.5m or customized

Yarn Type: E-glass

Standing temperature -70℃-260℃

Product name: PTFE coated fiberglass fabric

Coating/Finish/Surface Treatment: PTFE coated

Roll length: 50 meter or customized

Color: brown, black, white, grey, blue, or customized

Weave Type: plain woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass PTFE

Thickness: 0.3mm to 0.8mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: PTFE coated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers’ requirements

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for reinforcement in concrete pipes?

- Certainly! Fiberglass fabric proves to be an excellent option for reinforcing concrete pipes due to its robustness and lightweight nature, as well as its resistance to corrosion. By incorporating this material, concrete structures, including pipes, acquire enhanced strength and durability, resulting in an increased capacity to bear loads and a decreased likelihood of cracks or breakdowns. Moreover, the favorable thermal and chemical resistance properties of fiberglass fabric further solidify its appropriateness for reinforcing concrete pipes.

- Q: How is fiberglass fabric used in the packaging industry?

- Fiberglass fabric is widely used in the packaging industry for various purposes. It is known for its strength, durability, and heat resistance properties, making it an ideal material for packaging applications. One of the primary uses of fiberglass fabric in the packaging industry is as a reinforcement material. It is often used to reinforce cardboard boxes, crates, and other packaging materials to increase their load-bearing capacity. By adding a layer of fiberglass fabric, the packaging becomes more robust and can withstand heavier loads without getting damaged. Fiberglass fabric is also commonly used as a protective lining or wrapping material. It can be used to line the inside of packaging containers, such as drums or barrels, to provide an additional layer of protection. This helps to prevent any leakage or damage to the contents during transportation or storage. Furthermore, fiberglass fabric is utilized for insulation purposes in the packaging industry. It is commonly used to insulate packaging materials that need to maintain a specific temperature, such as cold chain packaging for perishable goods or thermal insulation for sensitive electronics. The heat resistance property of fiberglass fabric helps in maintaining the desired temperature inside the packaging, ensuring the safety and quality of the products. Additionally, fiberglass fabric is also used as a barrier material in the packaging industry. It can be used to create a moisture or vapor barrier by laminating it with other materials. This helps to protect the packaged goods from moisture, humidity, or other external factors that could potentially damage them. In summary, fiberglass fabric is extensively used in the packaging industry for reinforcement, protective lining, insulation, and barrier purposes. Its strength, durability, heat resistance, and insulating properties make it an excellent choice for various packaging applications, ensuring the safety and integrity of the packaged goods.

- Q: Can fiberglass fabric be used for reinforcement in automotive body panels?

- Yes, fiberglass fabric can be used for reinforcement in automotive body panels. It is a lightweight, strong, and durable material that can enhance the structural integrity and impact resistance of body panels.

- Q: What are the safety precautions to be taken while working with fiberglass fabric?

- To protect yourself from potential health hazards when working with fiberglass fabric, it is crucial to implement certain safety measures. Here are some important considerations: 1. Personal Protective Equipment (PPE): You must always wear the appropriate PPE, such as gloves, safety glasses, and a dust mask or respirator. This will help reduce your exposure to fiberglass particles and prevent respiratory issues. 2. Adequate Ventilation: Ensure that you work in a well-ventilated area to decrease the concentration of airborne fiberglass particles. If necessary, use exhaust fans or open windows to improve airflow. 3. Dust Reduction: Whenever possible, avoid cutting or sanding fiberglass fabric as these actions can release fine particles into the air. Use pre-cut fiberglass pieces whenever feasible. If cutting or sanding is necessary, do so in a controlled environment equipped with dust collection systems. 4. Hygiene: Maintain good hygiene practices by thoroughly washing your hands after handling fiberglass fabric. Avoid touching your face, particularly your eyes and mouth, to prevent accidental ingestion or irritation. 5. Proper Storage: Store fiberglass fabric in a cool, dry place away from direct sunlight or extreme temperatures. This will help preserve its integrity and minimize the risk of degradation or damage. 6. Training: Ensure that all personnel working with fiberglass fabric receive proper training on its handling and safety protocols. This includes understanding the potential health hazards, correct usage of PPE, and emergency procedures. 7. First Aid: Keep a fully stocked first aid kit readily available in case of accidental exposure or injury. Seek medical attention promptly if required. By adhering to these safety precautions, you can minimize the risks associated with working with fiberglass fabric and create a safer work environment.

- Q: Can fiberglass fabric be used for making shower curtains?

- Absolutely! When it comes to making shower curtains, fiberglass fabric is a stellar choice. Renowned for its durability, water resistance, and effortless upkeep, it's an ideal material. This fabric resists mildew and mold, which are frequent concerns in bathrooms, and can withstand the moisture and humidity found in shower areas. What's more, fiberglass fabric is a breeze to clean and doesn't absorb water, preventing saturation or unpleasant odors. All in all, opting for fiberglass fabric to create shower curtains ensures a lasting and hygienic solution for any bathroom.

- Q: Can fiberglass fabric be used for tents and awnings?

- Certainly, tents and awnings can be made using fiberglass fabric. This material is widely preferred for outdoor use because of its resilience, robustness, and ability to withstand extreme weather conditions. Despite being lightweight, it is remarkably sturdy, making it an optimal choice for constructing tents and awnings. Furthermore, fiberglass fabric possesses fire-resistant qualities and offers exceptional UV protection, ensuring a secure and pleasant outdoor experience. It also boasts excellent insulation properties, which help maintain a comfortable temperature inside the tent or beneath the awning. All in all, fiberglass fabric is a dependable and versatile option for tents and awnings, delivering both protection and endurance in diverse outdoor environments.

- Q: Can fiberglass fabric be used for reinforcement in chemical processing tanks?

- Yes, fiberglass fabric can be used for reinforcement in chemical processing tanks. Fiberglass is highly resistant to corrosion and can withstand a wide range of chemicals, making it an ideal material for reinforcing tanks in chemical processing industries. It is lightweight, durable, and has excellent mechanical properties, making it suitable for withstanding the harsh conditions of chemical processing.

- Q: What are the different fiberglass fabric weaves for flexibility?

- There are several different fiberglass fabric weaves that offer flexibility, including plain weave, twill weave, satin weave, and leno weave. These weaves provide varying degrees of flexibility and each has its own unique characteristics and uses.

- Q: Is fiberglass fabric suitable for use in medical implants?

- No, fiberglass fabric is not suitable for use in medical implants.

- Q: What about the leaking water made of fiberglass cloth?

- The water leakage in the water tank made of glass fiber cloth can be applied by asphalt. After the asphalt is solidified, water leakage can be prevented.

Send your message to us

Heat Resistant PTFE Coated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords