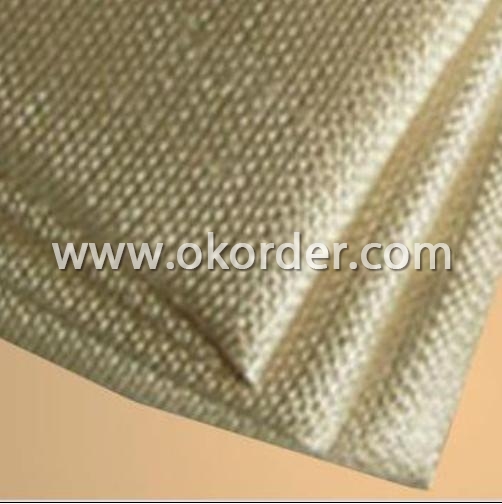

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General infor of Heat Treated E- Glass Fiber Fabric

It is fiberglass cloth impregnated our special formulated Hi-temp. resistance solutions which provides short temperature resistance of 1000C degree and increased continuous temperature resistance temperature up to 750C degree.

This impregnation also increases the products’ abrasion resistance and adds to its ability to withstand direct flame.

Product Feature of Heat Treated E- Glass Fiber Fabric

Mat width ranges from 50mm-3120mm Uniform density ensures consistent fiberglass content and mechanical properties of the final products the mats feayure good mat integrity ,low fuzz,less material waste and small roll dia meter. Excellent flexibility ensures good moldability with no springback at sharp angles, fast and consistent wet-out speed in high dry and wet tensile strength and good transparency.

Product Application of Heat Treated E- Glass Fiber Fabric

Emulsion Chopped Strand Mat is mainly applied to unsaturated polyester ,viny ester and epoxyresins. The product is most widely used in hand lay-up process and also can be used in filament winding. compression molding and continuous laminating processes. The typical end products including various panels, boats,ba

- Q: Can glass fiber textiles be used in the medical industry?

- Yes, glass fiber textiles can be used in the medical industry. Glass fiber textiles are made from fine strands of glass fibers which possess several desirable properties such as high strength, flexibility, and resistance to chemicals and heat. These properties make glass fiber textiles suitable for various applications in the medical industry. One major use of glass fiber textiles in the medical field is in the manufacturing of medical equipment and devices. For instance, glass fiber textiles can be used in the production of surgical gowns, masks, and other protective clothing for healthcare professionals. The high strength and durability of glass fiber textiles ensure that these protective garments provide effective barrier protection against pathogens and other contaminants. Glass fiber textiles can also be employed in wound care products. They can be used as reinforcement materials in bandages and dressings to provide additional strength and support to the wound area. The flexibility of glass fiber textiles allows for ease of movement and comfort for the patient while ensuring efficient wound healing. Moreover, glass fiber textiles can be utilized in the production of medical implants. The biocompatibility of these textiles ensures that they do not cause any adverse reactions or rejection when in contact with the human body. Glass fiber textiles can be incorporated into implantable devices such as bone screws, plates, and meshes, providing strength and stability to the implant structure. In addition, glass fiber textiles find applications in the field of tissue engineering, where they can be used as scaffolds for tissue regeneration. These textiles provide a three-dimensional structure to support the growth and development of new tissues. The porous nature of glass fiber textiles allows for the infiltration of cells, nutrients, and oxygen, facilitating tissue repair and regeneration. However, it is important to note that while glass fiber textiles offer several advantages in the medical industry, they may not be suitable for all applications. Some individuals may be allergic to glass fiber, and therefore, alternative materials should be considered in such cases. Additionally, proper sterilization techniques need to be employed to ensure the safety and effectiveness of glass fiber textiles in medical settings.

- Q: How are glass fiber textiles used in the medical industry?

- Various purposes in the medical industry utilize glass fiber textiles. Wound care is a significant area where these textiles are commonly employed. Dressings or bandages made from glass fiber textiles are utilized to cover and safeguard wounds. These textiles possess exceptional qualities such as high absorbency, breathability, and flexibility, which render them ideal for wound dressings. They also act as a protective barrier against bacteria and contaminants, thereby reducing the risk of infections. Additionally, glass fiber textiles are utilized in the production of medical devices and equipment. For example, they serve as reinforcement materials in orthopedic casts, splints, and braces. The strength and flexibility of these textiles ensure the stability and support required for proper immobilization and healing of fractures or injuries. Moreover, glass fiber textiles find applications in surgical procedures. They are utilized as surgical drapes, gowns, and masks to establish a sterile environment and prevent the transmission of infections during surgery. These textiles are lightweight, resistant to liquids and chemicals, and possess low linting properties, making them suitable for use in sterile environments. Furthermore, glass fiber textiles are incorporated into the production of prosthetic limbs. They contribute to the creation of a robust and lightweight framework for the prosthetic, ensuring durability and comfort for the patient. In summary, glass fiber textiles play a vital role in the medical industry by providing crucial solutions for wound care, medical device manufacturing, surgical procedures, and prosthetics. Their unique properties make them a reliable choice for ensuring patient safety, promoting healing, and enhancing the overall quality of healthcare.

- Q: Can glass fiber textiles be used in car body panels?

- Yes, glass fiber textiles can be used in car body panels. Glass fiber textiles are commonly used in the automotive industry to reinforce and strengthen various components, including car body panels. The use of glass fiber textiles in car body panels provides improved strength, durability, and lighter weight compared to traditional materials, making it a popular choice for manufacturers.

- Q: How do glass fiber textiles perform in terms of thermal insulation?

- Glass fiber textiles perform excellently in terms of thermal insulation. They have high thermal resistance and low thermal conductivity, which helps to prevent heat transfer and maintain desired temperatures. Additionally, their insulation properties are unaffected by moisture, making them ideal for a wide range of applications requiring thermal protection.

- Q: Can glass fiber textiles be used in insulation boards?

- Indeed, insulation boards can make use of glass fiber textiles. Owing to their exceptional thermal and acoustic insulation traits, glass fiber textiles are frequently employed as reinforcement materials in insulation boards. By endowing the boards with strength and stability, the glass fibers enhance their durability and resistance against harm. Moreover, the low thermal conductivity of glass fiber textiles allows for effective mitigation of heat transfer, thereby bolstering energy efficiency. Ultimately, when it comes to manufacturing insulation boards, glass fiber textiles emerge as a prevalent preference, offering efficacious insulation and heightened performance.

- Q: Can glass fiber textiles be dyed?

- Yes, glass fiber textiles can be dyed. However, the process of dyeing glass fiber textiles is different from dyeing other types of fibers such as cotton or wool. Due to the unique properties of glass fiber, it requires special dyes and techniques to achieve desired results. Traditional dyeing methods like immersion dyeing or direct application may not be suitable for glass fiber textiles. Instead, a common method used to dye glass fiber textiles is called "dope dyeing" or "solution dyeing." In this process, the dye is added to the liquid solution or "dope" before it is extruded into fibers. This allows the dye to be embedded within the structure of the glass fiber, resulting in a permanent and colorfast dyeing effect. Dope dyeing offers several advantages for glass fiber textiles. Firstly, it ensures even and consistent color distribution throughout the fibers, eliminating the risk of uneven or patchy dyeing. Secondly, it provides excellent colorfastness, making the dyed glass fiber textiles resistant to fading, washing, and sunlight exposure. Lastly, dope dyeing reduces environmental impact by eliminating the need for additional dyeing processes and reducing water and energy consumption. It's important to note that while glass fiber textiles can be dyed, the color options may be more limited compared to natural or synthetic fibers. Glass fiber textiles are commonly available in shades of white, black, or transparent, and achieving vibrant or custom colors may be challenging. Additionally, the specific dyeing technique and dyes used may vary depending on the manufacturer and the intended application of the glass fiber textiles. In conclusion, glass fiber textiles can be dyed using specialized dyeing techniques such as dope dyeing. This allows for permanent and colorfast dyeing, ensuring even color distribution and excellent color retention. However, it's important to consider the limitations in color options and consult with the manufacturer or a professional dyeing service for best results.

- Q: Can glass fiber textiles be used in geotextiles?

- Geotextiles, a kind of synthetic material used in civil engineering and construction projects, can indeed incorporate glass fiber textiles. Typically, geotextiles are crafted from polypropylene, polyester, or polyethylene, but there are certain applications where glass fiber textiles can also be utilized. The use of glass fiber textiles in geotextiles brings about numerous advantages. These textiles possess exceptional tensile strength, durability, and resistance to both chemicals and UV radiation, rendering them appropriate for geotextile purposes. They can effectively reinforce soil in various applications, such as stabilizing embankments, retaining walls, and slopes, thereby enhancing soil stability and strength. Moreover, in terms of drainage, glass fiber textiles can serve as efficient components in geotextiles. They can function as a filter fabric within drainage systems, preventing soil clogging and facilitating efficient water flow. Due to their high porosity and permeability, they allow water to pass through effortlessly while retaining soil particles to prevent erosion. In summary, glass fiber textiles offer a viable choice for geotextile applications due to their strength, durability, and resistance properties. Nonetheless, it is crucial to consider the specific application and project requirements when selecting the appropriate geotextile material to ensure optimal performance and longevity.

- Q: Are glass fiber textiles resistant to static electricity?

- Yes, glass fiber textiles are resistant to static electricity. This is because glass fiber has a low electrical conductivity, which means it does not allow the flow of electric charges easily. As a result, static electricity is not able to accumulate or transfer through glass fiber textiles. This property makes glass fiber textiles ideal for applications where static electricity must be controlled or prevented, such as in the production of electronics, cleanrooms, and other sensitive environments. Additionally, glass fiber textiles are also resistant to other forms of electrical interference, such as electromagnetic radiation.

- Q: Can glass fiber textiles be used in reinforcement of glass composites?

- Yes, glass fiber textiles can be used in the reinforcement of glass composites. Glass fiber textiles, also known as fiberglass, are made from fine fibers of glass that are woven into a fabric-like material. These textiles have excellent tensile strength, high stiffness, and good heat resistance, making them ideal for reinforcing glass composites. Glass composites are materials that are composed of a glass matrix reinforced with fibers. By incorporating glass fiber textiles into the composite, the overall strength and durability of the material are significantly enhanced. The glass fibers act as reinforcement, providing structural integrity and improving the mechanical properties of the composite. Glass fiber textiles can be used in various applications where glass composites are required, such as in the construction industry for making lightweight and strong panels, pipes, and tanks. They are also commonly used in the automotive industry for manufacturing components like body panels, bumpers, and interior parts. In addition to their strength and durability benefits, glass fiber textiles also offer advantages such as corrosion resistance, electrical insulation, and excellent dimensional stability. These properties make them highly suitable for use in reinforcement of glass composites, as they enhance the overall performance and longevity of the composite material. Overall, glass fiber textiles are widely used in the reinforcement of glass composites due to their exceptional mechanical properties and versatility.

- Q: Can glass fiber textiles be knit?

- Yes, glass fiber textiles can be knit. Knitting is a process of creating fabric by interlocking loops of yarn or thread, and it can be done with various materials, including glass fiber. Glass fiber textiles are made from thin strands of glass that are spun into yarns or rovings. These glass fiber yarns can then be used in knitting machines or hand-knitting techniques to create a knitted fabric. Knitted glass fiber textiles have several advantages, such as high strength, durability, and resistance to heat and chemicals. They are commonly used in applications such as insulation, reinforcement, and protective clothing.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Heat Treated E- Glass Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords