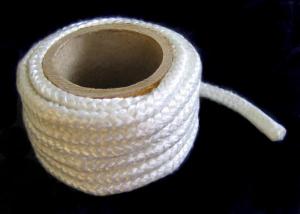

Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General info of Textured Fiberglass Round Braided

1. Fire fiberglass rope is made of continuous filament texturized C or E glass yarns and is extremely strong, resilient, and flexible.

2. Fire fiberglass rope are asbestos free, cause no harm to health, making them ideal replacements to asbestos ones.

3. For higher loads, the round braided and square braided ropes can be reinforced by steel wires.

4. Fire fiberglass rope also can be coated with graphite or vermiculite to increase thermal insulation and abrasive resistance.

Fire Fiberglass Rope Application:

1. Fire fiberglass rope are widely used as gasket for industrial ovens and furnaces, boilers and wood burning stoves.

Specifications of Textured Fiberglass Round Braided

1. Fire Fiberglass Rope 2. Round braided or square braided 3. Temperature: 450C-550C 4. Thickness:3mm-100mm

- Q:Can glass fiber textiles be used for making automotive parts or components?

- Indeed, glass fiber textiles can be utilized in the production of automotive parts or components. Commonly referred to as fiberglass, glass fiber textiles possess numerous characteristics that render them suitable for use within the automotive industry. To begin, glass fiber textiles are renowned for their exceptional strength-to-weight ratio, a critical factor in automotive applications where lightweight materials are sought after to enhance fuel efficiency and decrease emissions. Fiberglass components can be lighter than their metallic counterparts while still maintaining sufficient strength and durability. Furthermore, glass fiber textiles exhibit remarkable resistance to corrosion, chemicals, and temperature fluctuations. This renders them highly suitable for automotive parts that may be subjected to harsh environmental conditions, such as engine components, body panels, and interior trims. Moreover, fiberglass is an adaptable material that can be easily molded into intricate shapes, enabling the production of customized automotive parts with elaborate designs. This manufacturing flexibility aids in meeting the specific requirements and aesthetic preferences of automotive manufacturers. Additionally, glass fiber textiles possess excellent electrical insulation properties, a crucial aspect for components that handle electrical currents in vehicles, such as circuit boards and wiring harnesses. Fiberglass can serve as a reliable insulation barrier, safeguarding against short circuits and electrical malfunctions. Furthermore, glass fiber textiles exhibit outstanding acoustic properties, making them ideal for automotive parts that necessitate sound absorption or insulation, including interior panels and noise barriers. This contributes to an enhanced overall comfort and driving experience for passengers. In summary, glass fiber textiles present a viable choice for the production of automotive parts or components due to their impressive strength-to-weight ratio, resistance to corrosion and temperature variations, manufacturing versatility, electrical insulation properties, and acoustic capabilities. These qualities make fiberglass an appealing material for improving the performance, efficiency, durability, and comfort of automotive vehicles.

- Q:How do glass fiber textiles perform in terms of thermal insulation?

- Glass fiber textiles possess remarkable thermal insulation properties, recognized for their ability to effectively trap air within their structure. This is achieved through their composition, which incorporates delicate glass strands. This trapped air acts as a barrier, effectively reducing heat transfer through both conduction and convection. As a result, glass fiber textiles aid in maintaining stable temperatures in both hot and cold environments. Moreover, their low thermal conductivity guarantees minimal heat loss or gain, thus making them exceptionally efficient in conserving energy and minimizing heating or cooling expenses. All in all, glass fiber textiles are widely acknowledged for their outstanding thermal insulation capabilities.

- Q:Can glass fiber textiles be used in protective sleeves?

- Yes, glass fiber textiles can be used in protective sleeves. Glass fiber textiles offer excellent heat resistance and insulation properties, making them ideal for protecting against high temperatures, flames, and sparks. They are commonly used in industries such as welding, foundries, and automotive manufacturing, where workers need protection from potential hazards.

- Q:Can glass fiber textiles be used in wall coverings?

- Yes, glass fiber textiles can be used in wall coverings. Glass fiber textiles, also known as fiberglass textiles, are commonly used in various applications including wall coverings. They offer several advantages such as fire resistance, durability, and thermal insulation properties. Glass fiber textiles can be woven into different patterns and designs, making them versatile for use in wall coverings. They are also resistant to moisture and mold growth, which makes them suitable for areas with high humidity. Additionally, glass fiber textiles can provide acoustic insulation, reducing noise transmission through walls. Overall, glass fiber textiles are a viable option for wall coverings due to their functional and aesthetic properties.

- Q:Can glass fiber textiles be used in tents and awnings?

- Yes, glass fiber textiles can be used in tents and awnings. They are commonly used due to their strength, durability, and resistance to weather conditions. Glass fiber textiles provide excellent insulation and protection against UV rays, making them suitable for outdoor applications such as tents and awnings.

- Q:What is the lifespan of glass fiber textiles?

- The duration of glass fiber textiles can vary depending on several factors, such as the quality of the material, the specific application, and the level of maintenance. Generally, glass fiber textiles have a longer lifespan compared to other materials due to their durability and resistance to wear and tear. When utilized in industrial insulation, glass fiber textiles can endure for many decades. Their design allows them to withstand high temperatures, chemicals, and physical stress, making them well-suited for demanding environments. By ensuring proper installation and regular maintenance, glass fiber textiles can retain their integrity and effectiveness for an extended period. Nevertheless, it is crucial to consider certain factors that can impact the lifespan of glass fiber textiles. Prolonged exposure to extreme temperatures, excessive moisture, and harsh chemicals can gradually degrade the material, reducing its lifespan. Furthermore, improper handling or installation can also contribute to premature wear and tear. To maximize the lifespan of glass fiber textiles, it is essential to adhere to the manufacturer's guidelines for installation, usage, and maintenance. Conducting regular inspections and cleaning can aid in identifying any signs of damage or degradation, allowing for timely repairs or replacements. By properly caring for glass fiber textiles, their lifespan can be significantly prolonged, ensuring continued performance and cost-effectiveness.

- Q:Are glass fiber textiles resistant to chemicals used in cleaning products?

- Generally, glass fiber textiles possess resistance to the chemicals commonly employed in cleaning products. Manufactured from molten glass that is skillfully spun into fine threads, glass fibers create a resilient and sturdy material. This innate strength and durability enable glass fiber textiles to endure exposure to a broad array of chemicals without experiencing significant deterioration or harm. Be it acid-based cleansers, alkaline solutions, or other cleansing agents, glass fiber textiles usually possess the ability to resist the corrosive impact of these chemicals. This resistance renders them suitable for utilization in diverse cleaning applications, including industrial settings where harsh chemicals are frequently utilized. However, it is crucial to acknowledge that the precise chemical resistance of glass fiber textiles may differ based on the composition and coating of the fibers. Therefore, it is always advisable to refer to the manufacturer's specifications or carry out a small-scale compatibility test before employing cleaning products on glass fiber textiles.

- Q:Can glass fiber textiles be used in reinforcement of wood products?

- Yes, glass fiber textiles can be used in the reinforcement of wood products. Glass fiber textiles are known for their high strength and durability, making them an effective material for reinforcing wood structures. By incorporating glass fiber textiles into wood products, such as plywood or composite materials, the overall strength and stability of the wood can be significantly enhanced. Additionally, glass fiber textiles can also provide resistance against moisture, fire, and pests, further increasing the longevity and performance of wood products.

- Q:Can glass fiber textile be used in window treatments?

- Indeed, window treatments can incorporate glass fiber textiles. Renowned for their durability, strength, and ability to withstand UV rays, these textiles prove ideal for this purpose. Whether utilized as curtains, blinds, or shades, they effectively offer privacy, light control, and heat insulation. Moreover, their flame-resistant nature enhances the safety of window treatments. Furthermore, their effortless cleaning and maintenance make them a pragmatic option for both residential and commercial settings.

- Q:Can glass fiber textiles be fire-resistant?

- Glass fiber textiles possess fire-resistant qualities. Molten glass is utilized to create thin strands of glass fibers. These strands are then woven into textiles and can be treated with fire-resistant coatings or additives to augment their fire resistance properties. The glass fibers themselves possess a high melting point, approximately 1400 to 1600 degrees Celsius, rendering them naturally fire-resistant. Furthermore, the structure of glass fibers permits low thermal conductivity, preventing the efficient transfer of heat and further enhancing their fire resistance. Overall, glass fiber textiles offer exceptional fire resistance properties, making them suitable for a wide range of applications that prioritize fire safety, such as protective clothing, curtains, and insulation materials.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords