Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Refractory | Grade: | ST (Standard) | Working Temperature: | 1050C |

| Place of Origin: | China (Mainland) | Brand Name: | SUNTHERM | Model Number: | SS wire reinforced |

| Certificate: | BV,SGS,CE,ROHS,ISO9001:2000 | Sample: | Available | MDS Availabel: | Yes |

Packaging & Delivery

| Packaging Detail: | Woven bag , carton or as your demand to custom |

| Delivery Detail: | Within 15 days after received the deposit. |

Specifications

Ceramic fiber textile

AL2O3:45%

Fiber diameter:3-5um

Temperature:1050C ISO9000 certificate

ceramic fiber rope includes square braided rope, round braided rope and twisted rope. All are made from high quality ceramic fiber material. The rope is reinforced with fiberglass filament, or alloy steel wire. Fiberglass filament reinforced rope can work in the temperature below 650C with electric insulating property, while alloy steel wire can work in the temperature 1100C with higher strength. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property .The three different styles are designed to fit different application needs: twisted rope is a soft rope, while square and round braid are more dense and solid.

Product information

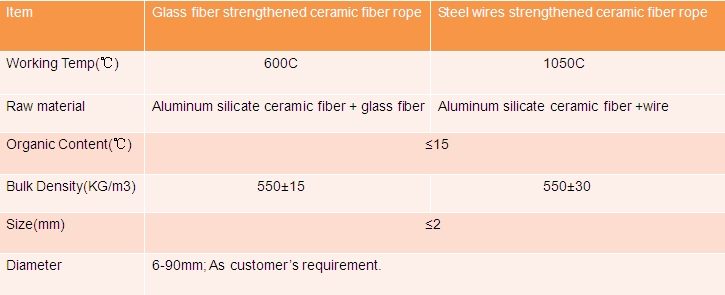

Item | Ceramic fiber rope |

Type | Glass fiber strengthened ceramic fiber rope Steel wires strengthen ceramic fiber rope |

Applications | • High temperature static seal e.g. door joint or gaskets for flanges • Fire protection e.g. fires proof curtain against welding spark. • The protection of cable, fuel tubes etc • Fireproof twine, wrap, cover etc • Pipe or round duct insulation lagging • Asbestos substitute |

Features | •Excellent high temperature stability • Excellent tensile strength • Excellent thermal electrical insulation • Excellent chemical stability resistance • Low thermal conductivity. |

Packing | In plastic bags, in cartons or according customers requirement. |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Certificate | ISO9001-2000, ISO14001-2000, CE ,SASO,SGS . |

Technical data

- Q: Can glass fiber textiles be used in surgical implants?

- Yes, glass fiber textiles can be used in surgical implants. Glass fibers are known for their high strength and biocompatibility, making them suitable for various medical applications, including surgical implants. They are commonly used as reinforcement materials in composite implants, such as bone plates, screws, and rods, to provide added strength and stability. Glass fiber-reinforced composites have been used successfully in orthopedic implants, dental implants, and even in soft tissue repair. These textiles are also used as a scaffold material in tissue engineering, where they can support cell growth and tissue regeneration. However, it is important to note that the biocompatibility of glass fiber textiles can vary depending on the composition and surface treatment. Therefore, thorough testing and evaluation are necessary to ensure their safety and efficacy in surgical implants.

- Q: How do glass fiber textiles perform in terms of air permeability?

- Glass fiber textiles are typically not very permeable to air, meaning that they do not allow a significant amount of air to pass through them. The tightly woven or knitted structure of these textiles hinders the movement of air, making them effective at preventing air from leaking or infiltrating. This characteristic is advantageous in situations where airtightness is desired, such as in insulation materials, protective clothing, or air filters. However, it is important to consider that the air permeability of glass fiber textiles can vary depending on factors such as the specific weave or knit pattern, the thickness of the fibers, and any additional coatings or treatments applied to the fabric.

- Q: Are glass fiber textiles resistant to UV rays?

- Yes, glass fiber textiles are generally resistant to UV rays. Glass fibers themselves have excellent resistance to UV degradation due to their inorganic nature. This means that glass fiber textiles, which are made from these fibers, also inherit this resistance. UV rays from the sun can cause damage to many materials over time, including fading, weakening, and degradation. However, glass fiber textiles can withstand prolonged exposure to UV rays without significant deterioration, making them highly suitable for outdoor applications such as awnings, canopies, and outdoor furniture. It is important to note that while glass fiber textiles are resistant to UV rays, they are not completely immune to the effects of prolonged exposure, and their performance may vary depending on the specific manufacturing process and any additional coatings or treatments applied to the textiles. Therefore, it is always recommended to follow the manufacturer's guidelines and take proper care and maintenance measures to ensure the longevity of glass fiber textiles in outdoor settings.

- Q: How are glass fiber textiles different from other types of textiles?

- Glass fiber textiles are different from other types of textiles primarily because of the material they are made from. While most textiles are produced from natural fibers like cotton, silk, or wool, glass fiber textiles are made from synthetic fibers composed of glass. One key difference between glass fiber textiles and other textiles is their strength and durability. Glass fibers are known for their high tensile strength, meaning they can withstand a significant amount of tension without breaking. This makes glass fiber textiles ideal for applications that require strength and stability, such as reinforcement materials in composites or industrial fabrics. Glass fiber textiles also have excellent heat resistance properties. Unlike natural fibers that can burn or melt when exposed to high temperatures, glass fibers are able to withstand extreme heat without losing their structural integrity. This makes glass fiber textiles suitable for applications in high-temperature environments, such as insulation materials or protective clothing for firefighters. Another significant difference is the transparency of glass fiber textiles. Due to the nature of the glass material, these textiles can be made to have varying levels of transparency or translucency. This makes them suitable for applications like window coverings or curtains where a certain amount of light transmission is desired. In addition, glass fiber textiles are also highly resistant to chemical corrosion. They are not affected by most chemicals, acids, or alkalis, making them a preferred choice in industries like chemical processing or wastewater treatment. However, it is worth noting that glass fiber textiles may not be as comfortable or flexible as natural fiber textiles. Due to their synthetic nature, glass fibers can be stiffer and less breathable. This makes them less suitable for applications like clothing or bedding, where comfort and softness are important factors. Overall, glass fiber textiles offer unique properties that differentiate them from other types of textiles. Their strength, heat resistance, transparency, and chemical resistance make them valuable for a wide range of industrial and specialized applications.

- Q: Are glass fiber textiles resistant to insect damage?

- Yes, glass fiber textiles are highly resistant to insect damage.

- Q: How do glass fiber textiles affect waste management?

- Glass fiber textiles can have a significant impact on waste management practices. Firstly, glass fiber textiles are known for their durability and long lifespan. This means that products made from glass fiber textiles, such as industrial filters, can be used for extended periods before needing to be replaced. This reduces the amount of waste generated from frequently discarded textiles. Moreover, glass fiber textiles are highly resistant to heat, chemicals, and corrosion, making them ideal for various industrial applications. For instance, in the wastewater treatment industry, glass fiber textiles are used in filtration systems to remove solid waste and contaminants from water. By effectively trapping and containing these pollutants, glass fiber textiles contribute to the efficient management of waste and protect the environment by preventing the release of harmful substances into water bodies. Additionally, glass fiber textiles can also be recycled. When these textiles reach the end of their useful life, they can be collected and processed to create new products. Recycling glass fiber textiles not only reduces the amount of waste sent to landfills but also conserves natural resources and reduces the energy required for manufacturing new textiles. Furthermore, the use of glass fiber textiles in waste management can also have a positive impact on public health. For example, in the construction industry, glass fiber textiles are often used in the manufacturing of insulation materials. By effectively insulating buildings, these textiles contribute to energy efficiency, reducing the need for heating and cooling systems. This, in turn, leads to lower energy consumption and fewer greenhouse gas emissions, resulting in a healthier and more sustainable environment. In conclusion, glass fiber textiles play a crucial role in waste management. Their durability, resistance to various elements, recyclability, and contribution to energy efficiency make them an environmentally friendly choice. By reducing waste generation, efficiently filtering contaminants, and promoting recycling, glass fiber textiles significantly contribute to waste management practices and help create a more sustainable future.

- Q: How do glass fiber textiles affect the drapability of fabrics?

- The drapability of fabrics can be significantly influenced by glass fiber textiles, also known as fiberglass textiles. When glass fibers are added to a fabric, it can increase its stiffness and rigidity, preventing it from naturally draping. This is because glass fibers, compared to commonly used natural or synthetic fibers in textiles, have a high tensile strength and are relatively inflexible. When glass fiber textiles are integrated into fabrics, they create a network of interlocking fibers that provide structure and stability to the material. This can be advantageous in certain applications, such as industrial or technical textiles, where a more rigid fabric is desired. However, in garments or home furnishings where drape and fluidity are important, the presence of glass fibers can be a disadvantage. The stiffness caused by glass fiber textiles can limit the movement and flow of the fabric, resulting in a less natural drape. Fabrics containing glass fibers may not hang as smoothly or gracefully as those without, and may appear more rigid when worn or used for drapery. Furthermore, the presence of glass fibers can alter the feel and texture of the fabric, potentially making it less comfortable against the skin. It is important to note that the impact of glass fiber textiles on drapability can vary depending on the concentration and distribution of the fibers within the fabric. Higher concentrations of glass fibers or a more tightly woven or knitted structure generally have a more significant effect on drapability. Overall, although glass fiber textiles can offer advantages in terms of strength and stability, they can negatively affect the drapability of fabrics. Designers and manufacturers should carefully consider the intended application and desired characteristics of a fabric before deciding whether to incorporate glass fibers or explore other alternatives.

- Q: Can glass fiber textile be used in air filters?

- Yes, glass fiber textile can be used in air filters. Glass fiber is a common material used in air filters due to its high efficiency in capturing small particles and its ability to withstand high temperatures. The interlaced structure of glass fiber textile provides a large surface area for trapping airborne particles, making it an effective filter medium. Additionally, glass fiber is non-combustible and does not release harmful chemicals, making it a safe choice for air filtration. It is commonly used in various air filtration applications, including HVAC systems, industrial air filters, and residential air purifiers.

- Q: Does glass fiber textile have any health risks?

- Glass fiber textiles carry certain potential health hazards. When dealing with these textiles, it is crucial to take necessary precautions in order to minimize exposure to the fibers. Inhaling glass fibers can cause irritation to the respiratory system and result in discomfort, including coughing, wheezing, and shortness of breath. Prolonged and repeated contact with glass fibers can also lead to more severe health problems, such as lung scarring and the development of respiratory illnesses like bronchitis or fibrosis. To minimize health risks, it is advisable to wear proper personal protective gear, such as gloves, goggles, and respiratory masks, while handling glass fiber textiles. Working in well-ventilated areas and employing appropriate cutting and handling techniques to prevent the creation of dust or airborne particles are also important. Nevertheless, it is important to note that the health risks associated with glass fiber textiles are generally low when proper safety measures are adhered to. Moreover, due to their exceptional properties, such as high strength and resistance to heat and chemicals, glass fiber textiles are widely used in various industries, including insulation, automotive, and aerospace.

- Q: Can glass fiber textiles be used in tents and awnings?

- Yes, glass fiber textiles can be used in tents and awnings. Glass fiber textiles, also known as fiberglass, have several properties that make them suitable for these applications. Firstly, fiberglass is lightweight, which makes it easy to transport and set up. Additionally, it has high tensile strength, meaning it can withstand tension and resist tearing. This makes it ideal for supporting the structure of tents and awnings. Moreover, fiberglass textiles are highly durable and can withstand exposure to harsh weather conditions, such as rain, wind, and UV radiation. They are also resistant to rot, mold, and mildew, making them a long-lasting choice for outdoor applications. Furthermore, fiberglass textiles can provide excellent insulation properties, helping to maintain a comfortable temperature inside tents and awnings. Overall, glass fiber textiles offer a reliable and versatile option for the construction of tents and awnings.

Send your message to us

Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords