Glass Fiber Textile Reinforced Microporous Insulation Board for Ladle Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | M5100 | service temperature, max.: | 1150 C | Thermal conductivity, @800 C: | 0.035 W/m.K |

| typical density: | 280 kgs/m3 |

Packaging & Delivery

| Packaging Details: | wooden cases |

| Delivery Detail: | 10 days |

Product Description

M5100 Panel is rigid finishing from microporous technology , with opcified blend of filament reinforced fumed silica, which provides a superb thermal performance.

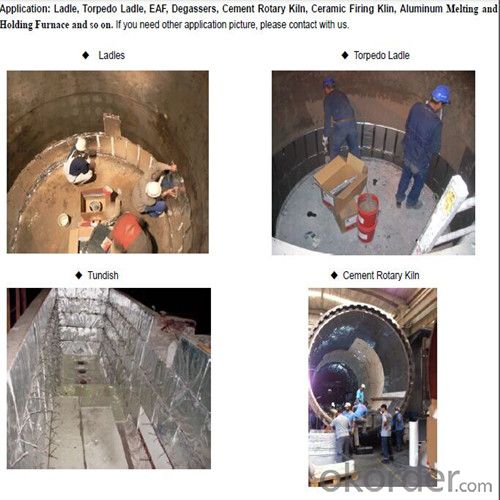

It is an ideal back-up insulation for various industry where the high temperature is needed, with a long time exposure of 1150 °C at highest.

M5100 Panel ---Various coverings : Naked Panels, Aluminium Foil covering, E-class Fibre Cloth Covering, Fibre Paper covering.

M5100 Panel—Four Grades available : 850 , 1000, 1100, 1200

Properties & Advantages

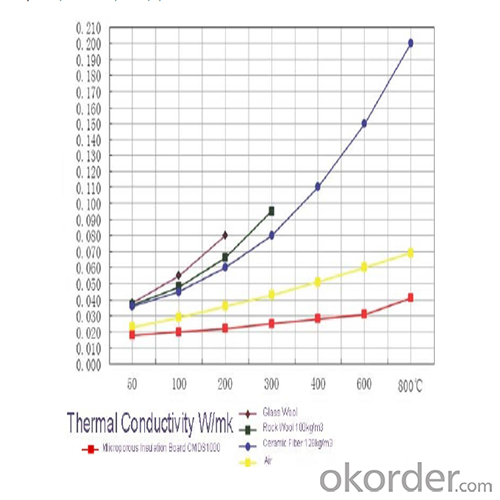

Extremely low thermal conductivity

High thermal stability

High compressive strength

No harmful respirable fibres

Free of organic binders

Environmentally friendly

Resistant to most chemicals

Non combustible

Easy to handle

Typical Applications

Back-up insulation in industrial furnaces

Fuel cells (SOFC)

Thermal Batteries

Aluminium industry ( launders,Smelter.etc. )

Glass & ceramics industry

Petrochemical industry (cracking furnace, reformer)

Black box & VDR (Voyage Data Recorder)

Data loggers

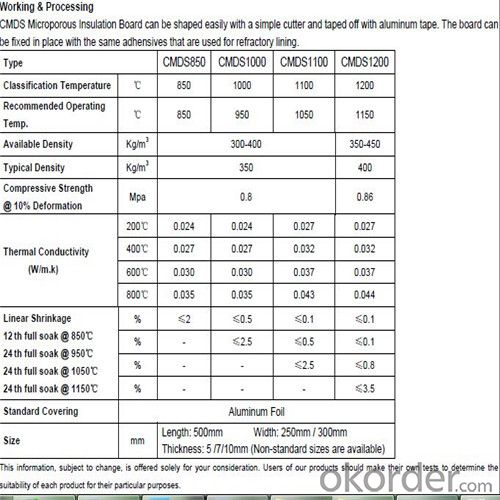

Working & Processing

M5100 can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Technical Data for for Micropore Insulation Board ,Heat Insulation materials

| Description | MISSION STD Panel M5100 | ||||

| Classification Temperature | 0C | 850 | 1000 | 1100/1100S | 1200/1200S |

| Long time Exposure | 850 | 950 | 1050/1000 | 1150/1100 | |

| Nominal Density | [kg/m3] | 260-280 | 260-280 | 400-450 | 450-550 |

| Typical Density | 280 | 280 | 450 | 500 | |

| Compression Strength | [MPa] | 0.32 | 0.32 | 0.72 | 0.8 |

| @10% deformation (ASTM C-165) | |||||

| Thermal Conductivity | |||||

| 200 0C | W/m.K | 0.022 | 0.022 | 0.024 0.028 | 0.027 0.029 |

| 400 0C | W/m.K | 0.025 | 0.025 | 0.028 0.032 | 0.032 0.035 |

| 600 0C | W/m.K | 0.028 | 0.028 | 0.032 0.038 | 0.037 0.042 |

| 800 0C | W/m.K | 0.033 | 0.033 | 0.035 0.045 | 0.043 0.046 |

| Specific Heat Capacity | |||||

| 200 0C | [KJ/Kg K] | 0.85 | 0.86 | 0.86 | 0.89 |

| 400 0C | [KJ/Kg K] | 0.95 | 0.96 | 0.97 | 0.99 |

| 600 0C | [KJ/Kg K] | 1.02 | 1.03 | 1.04 | 1.05 |

| 800 0C | [KJ/Kg K] | 1.07 | 1.08 | 1.08 | 1.08 |

| Linear Shrinkage | |||||

| 12h full soak @ 850 0C | % | ≤2 | ≤0.5 | ≤0.1 ≤0.1 | ≤0.1 ≤0.1 |

| 24h full soak @ 950 0C | - - - | ≤2.5 | ≤0.5 ≤0.1 | ≤0.5 ≤0.5 | |

| 24h full soak @ 1050 0C | - - - | - - - | ≤2.5 - - - | ≤2.5 ≤2.5 | |

| 24h full soak @ 1150 0C | - - - | - - - | - - - - - - | ≤3.5 - - - | |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Are glass fiber textiles suitable for electrical insulation?

- Yes, glass fiber textiles are suitable for electrical insulation. Glass fiber textiles are made from thin strands of glass that are woven into a fabric-like material. This material has excellent electrical insulating properties due to the non-conductive nature of glass. It is capable of resisting high voltages and does not conduct electricity, making it ideal for applications where insulation is required to prevent electrical shocks or short circuits. Additionally, glass fiber textiles have good thermal resistance and can withstand high temperatures, which further enhances their suitability for electrical insulation. They are widely used in various industries such as electrical engineering, electronics, and aerospace for applications such as insulating wires, cables, and electrical equipment.

- Q: Can glass fiber textile be stretched?

- Yes, glass fiber textile can be stretched to a certain extent. However, it has a relatively low elasticity compared to other fibers such as nylon or spandex.

- Q: What is the cost of glass fiber textiles compared to other materials?

- The cost of glass fiber textiles is generally lower compared to other materials such as carbon fiber or Kevlar. However, it can vary depending on the specific application and quality of the material.

- Q: How do glass fiber textiles contribute to electrical conductivity?

- Glass fiber textiles do not contribute to electrical conductivity as they are insulators.

- Q: Can glass fiber textiles be used in reinforcement of wool fibers?

- Yes, glass fiber textiles can be used in reinforcement of wool fibers. Glass fiber textiles, often referred to as fiberglass, are known for their high strength and durability. By combining them with wool fibers, which are known for their natural insulation and moisture-wicking properties, the resulting composite material can have enhanced strength, improved thermal properties, and increased resistance to wear and tear. This makes it suitable for various applications such as in the production of insulation materials, protective clothing, and even in the automotive and aerospace industries. Additionally, the combination of glass fiber textiles and wool fibers offers a balance between natural and synthetic materials, making it an environmentally friendly option as well.

- Q: How do glass fiber textiles resist stretching?

- Glass fiber textiles resist stretching due to the inherent strength and rigidity of the glass fibers woven or knitted together. The glass fibers provide high tensile strength, preventing elongation and maintaining the fabric's shape even under tension.

- Q: Can glass fiber textiles be used for making industrial curtains or partitions?

- Yes, glass fiber textiles can be used for making industrial curtains or partitions. Glass fiber textiles are known for their high strength, durability, and fire resistance properties, making them an excellent choice for industrial applications. These textiles are capable of withstanding harsh environments, including high temperatures and chemicals, making them ideal for use in industrial settings where protection and safety are paramount. Additionally, glass fiber textiles are lightweight and flexible, allowing for easy installation and movement of industrial curtains or partitions as needed. Overall, glass fiber textiles are a suitable material for making industrial curtains or partitions due to their superior strength, durability, fire resistance, and flexibility.

- Q: How do glass fiber textiles perform in terms of fire resistance?

- Glass fiber textiles have excellent fire resistance properties. Due to their inorganic nature, they do not readily burn or support the spread of flames. They have a high melting point and do not release toxic smoke or gases when exposed to fire. This makes them a preferred choice in applications where fire safety is a concern, such as in protective clothing, insulation materials, and building materials.

- Q: What are the different surface patterning options for glass fiber textile?

- Glass fiber textiles offer various options for surface patterning. These include: 1. Plain Weave: The simplest and most common type of surface patterning for glass fiber textiles. It involves interlacing fibers in an over-under pattern, resulting in a smooth and uniform surface. 2. Twill Weave: Characterized by a diagonal pattern created by interlacing fibers. This type of surface patterning enhances the strength and flexibility of the glass fiber textile. 3. Satin Weave: Another popular option known for its lustrous and smooth surface. Achieved by floating warp threads over multiple weft threads, satin weave provides flexibility and a luxurious appearance. 4. Jacquard Weave: Allows for intricate and complex designs to be woven into the glass fiber textile. Achieved using a special loom with a Jacquard attachment that controls individual warp threads, resulting in detailed patterns. 5. Embossed or Textured Patterns: Glass fiber textiles can also be patterned through embossing or adding textures. Embossed patterns are created by pressing the fibers onto a heated patterned roller, resulting in raised designs. Textured patterns can be achieved by adding materials like resins or foams, creating a three-dimensional surface. 6. Laser Etching: A modern technique that uses a laser to remove specific areas of the glass fiber textile, creating precise and intricate patterns. This method allows for high customization and detailed designs. Overall, the choice of surface patterning for glass fiber textiles depends on the desired aesthetics, functionality, and performance requirements of the end product. Each option offers unique characteristics and can be tailored to specific needs.

- Q: How do glass fiber textiles affect water usage?

- Glass fiber textiles do not directly affect water usage as they are not water-intensive materials. Unlike natural fibers like cotton or wool, which require significant amounts of water during cultivation and processing, glass fiber textiles are made from synthetic materials that do not rely on water resources. However, it is important to note that the production of glass fiber textiles still requires energy and resources, including water, for the manufacturing process. Water may be used for cooling or cleaning purposes during production, but the overall water consumption is relatively low compared to other textile materials. Furthermore, glass fiber textiles have certain properties that can indirectly contribute to water conservation. For instance, they are highly durable and resistant to moisture, which means they require less frequent washing or cleaning compared to other fabrics. This reduces the need for water usage in maintaining and caring for these textiles. Overall, while glass fiber textiles themselves do not directly impact water usage, their production and unique properties can have positive implications for water conservation when compared to other textile materials.

Send your message to us

Glass Fiber Textile Reinforced Microporous Insulation Board for Ladle Heat Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords