Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

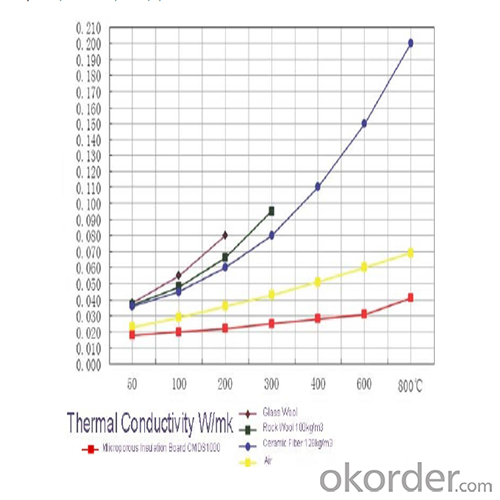

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

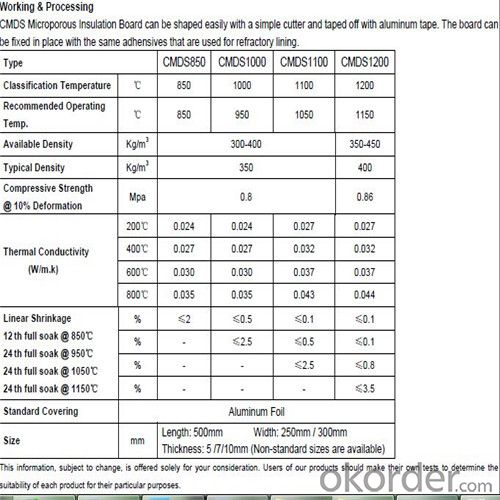

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q:Are glass fiber textiles suitable for protective clothing?

- Yes, glass fiber textiles are suitable for protective clothing. They offer excellent resistance to heat, fire, and chemicals, making them an ideal choice for industries where workers are exposed to these hazards. Additionally, they have high strength and durability, providing effective protection against cuts and abrasions.

- Q:Can glass fiber textiles be used for reinforcement in rubber products?

- Glass fiber textiles are suitable for reinforcing rubber products, as they possess excellent mechanical properties such as high tensile strength, stiffness, and dimensional stability. These properties make them ideal for enhancing the overall strength and durability of rubber materials. By incorporating glass fiber textiles into rubber products, their resistance to wear, tear, impact, and fatigue can be improved. The even distribution of stress throughout the rubber matrix, facilitated by the glass fibers, prevents deformation or failure under mechanical loads. This reinforcement also helps to maintain the shape and structure of the rubber product over time. Furthermore, glass fiber textiles can be easily integrated into the manufacturing process and are highly compatible with rubber materials. They can be added as a layer, in the form of chopped fibers, continuous strands, or woven fabrics, depending on the desired mechanical properties and performance requirements of the rubber product. In conclusion, glass fiber textiles are commonly used for reinforcing rubber products due to their exceptional mechanical properties and compatibility with rubber materials. They enhance the strength, durability, and dimensional stability of rubber products, making them suitable for a range of applications such as automotive parts, industrial seals, conveyor belts, hoses, and gaskets.

- Q:What do 02 and 04 of fiberglass cloth refer to?

- Glass fiber fabric is a roving fabric, and it is an important base material of hand sticking glass fiber reinforced plastic. The main strength of cloth on the latitude and longitude direction of fabric, weft or warp for high strength occasions, can also be woven into unidirectional cloth, it can be more roving to warp or weft arrangement, single warp and single weft cloth to cloth. The roving roving is made up of parallel filaments or parallel filaments. According to the composition of glass, roving can be divided into E-GLASS alkali free glass roving and alkali glass roving in C-GLASS.

- Q:What about polyester fiber and flannel? Is flannel made of polyester?

- Polyester fiber is what we usually call "polyester."",Is a kind of refined by the petroleum chemical fiber fabric, polyester taffeta, polyester pongee, peach skin is common.

- Q:Do glass fiber textiles have good tensile strength?

- Glass fiber textiles possess impressive tensile strength. Renowned for their exceptional strength-to-weight ratio and superior tensile strength, glass fibers can withstand substantial tension without fracturing or distorting. Consequently, they prove highly suitable for sectors necessitating robust and long-lasting materials, including construction, aerospace, and automotive industries. Furthermore, glass fiber textiles exhibit resistance against corrosion, moisture, and extreme temperatures, thereby fortifying their tensile strength and durability. Consequently, these textiles garner widespread recognition for their remarkable tensile strength, rendering them a favored option across diverse industrial and commercial applications.

- Q:Are glass fiber textiles resistant to warping?

- Glass fiber textiles, due to their construction with fine strands of glass, possess the ability to withstand warping. These textiles are woven together to create a fabric that is both strong and flexible. The glass fibers themselves exhibit high tensile strength and minimal thermal expansion, resulting in exceptional resistance to warping. Consequently, glass fiber textiles retain their shape and integrity, even when subjected to extreme temperatures or pressure. Moreover, these textiles offer resistance against moisture, chemicals, and UV radiation, which further bolsters their capacity to resist warping. Overall, the dimensional stability of glass fiber textiles is highly regarded, making them a popular choice in industries where warping is a concern, such as aerospace, automotive, and construction.

- Q:What are the advantages of using glass fiber textiles in construction?

- Glass fiber textiles have numerous benefits when used in construction. Firstly, they possess exceptional strength and durability, exhibiting a high tensile strength that enables them to withstand heavy loads and resist deformation. This makes them particularly suitable for applications requiring structural reinforcement, such as the reinforcement of concrete or providing support in areas prone to earthquakes or other natural disasters. Secondly, glass fiber textiles are lightweight in comparison to traditional construction materials like steel or concrete. This characteristic makes them easier to handle and transport, reducing the overall weight of the structure and facilitating faster construction and installation. Thirdly, glass fiber textiles demonstrate remarkable resistance to corrosion and moisture. Unlike metals, which can rust or deteriorate over time, glass fiber textiles do not rot, corrode, or degrade when exposed to moisture or harsh environmental conditions. Consequently, they are ideal for applications in humid or wet environments, such as swimming pools, bathrooms, or coastal areas. Moreover, glass fiber textiles possess excellent thermal and acoustic insulation properties. They effectively trap and retain heat, leading to reduced energy consumption and improved energy efficiency in buildings. Furthermore, they absorb and dampen sound, contributing to improved acoustics and reduced noise pollution within the structure. Furthermore, glass fiber textiles are fire-resistant. They do not burn, emit toxic fumes, or contribute to the spread of flames, making them a safe choice for construction. This fire resistance helps prevent the rapid spread of fires and potentially saves lives. Lastly, glass fiber textiles offer design flexibility. They can be easily molded, shaped, or woven into various forms, allowing architects and designers to create aesthetically pleasing structures. Additionally, they can be colored, painted, or coated to achieve any desired finish or appearance. In conclusion, the utilization of glass fiber textiles in construction provides numerous advantages including strength, lightweight nature, resistance to corrosion and moisture, thermal and acoustic insulation properties, fire resistance, and design flexibility. These characteristics make them a valuable material choice for a wide range of construction applications.

- Q:Can glass fiber textiles be used in protective clothing?

- Yes, glass fiber textiles can be used in protective clothing. Glass fiber textiles are known for their high strength, heat resistance, and excellent insulation properties. These qualities make them suitable for protective clothing applications where protection against heat, fire, and chemicals is required. Additionally, glass fiber textiles can also provide protection against cuts and abrasions, making them a versatile choice for various industries such as firefighting, manufacturing, and construction.

- Q:Can glass fiber textile be exposed to sunlight?

- Glass fiber textile can indeed be exposed to sunlight. Its durability and resistance to UV radiation are well-known. This makes it a popular choice for various outdoor applications like awnings, umbrellas, and outdoor furniture, which are often subjected to prolonged sunlight exposure. Nevertheless, it is crucial to acknowledge that extended exposure to sunlight can lead to gradual fading or discoloration of the textile. To maintain their longevity and prevent any potential damage from the sun's rays, it is essential to properly maintain and regularly clean glass fiber textiles.

- Q:Can glass fiber textiles be used in military applications?

- Glass fiber textiles are indeed applicable in military contexts. Renowned for their robustness and durability, these textiles are well-suited for diverse military purposes. They find utility in fabricating military uniforms, bulletproof vests, and other protective equipment. Their ability to withstand high temperatures, flames, and chemicals is vital in military settings. Moreover, glass fiber textiles are employed in constructing military tents, camouflage nets, and other textile structures. In summary, glass fiber textiles offer a multitude of advantages and can be effectively employed in a range of military applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords