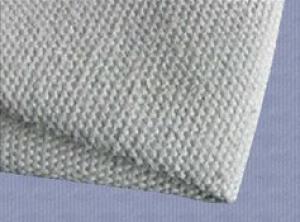

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Twisted Rope | Application: | Heat Insulation | Thickness: | 4-60mm |

| Width: | 4-60mm | Length: | 30m | Grade: | HA (High Aluminum) |

| Chemical Composition: | AL2O3+SIO2 | Ultimate Strength (≥ MPa): | 0.04 | Working Temperature: | 1260 |

| Fiber Diameter: | 2-5um | Thermal Conductivity: | 0.075-0.175 w/m.k | Shrinkage (1800℉, 3h): | <=-3 |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ceramic textile fiber rope | |

| Color: | White | fire-resistant rope density: | 600-620kg/m3 | ceramic rope: | ceramic rope braided |

| fire resistant rope: | ceramic textile fiber rope |

Packaging & Delivery

| Packaging Detail: | ceramic textile fiber rope package: carton with inner plastic bag |

| Delivery Detail: | 15days after receiving advance payment |

Production description of ceramic textile fiber rope

Iterm | Ceramic fiber ceramic rope twisted |

Type | Ceramic fiber ceramic rope twisted |

Ceramic fiber ceramic rope twisted | |

Ceramic fiber ceramic rope twisted | |

Characteristics | ** Good thermal insulation |

** Excellent high temperature strength | |

** Good electrical insulation properties | |

** High chemical stability | |

** Low thermal conductivity | |

Typical Use | Hightemperature pipe insulation and seal,cable insulation coating, flexible expansion joint connection,coke oven opening seal |

MOQ | 30m |

FOB Price | 4-6.5 USD/KG |

Port | Qingdao |

Payment Terms | L/C, D/A, D/P, T/T |

Packing | Carton with inner plastic bags |

Delivery | Within 15 days after delivery deposit |

Certificate | ISO9001, MSDS |

Product details of ceramic textile fiber rope

Type | Ref.No. | Reinforcement | Work. Temp (°C) | Density (kg/m3) | Size (mm) |

Twisted Rope | C101TG | Glass filament | 1260 | 600-620 | 6-40 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-40 | |

Round Braided Rope | C101TG | Glass filament | 1260 | 600-620 | 6-160 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-160 |

- Q: Are glass fiber textiles resistant to tearing or ripping?

- Yes, glass fiber textiles are highly resistant to tearing or ripping due to their strong and durable nature.

- Q: Can glass fiber textiles be used in automotive carpets?

- Yes, glass fiber textiles can be used in automotive carpets. Glass fiber textiles are known for their strength, durability, and flame resistance, making them suitable for automotive applications. They can provide added reinforcement and structural integrity to carpets, enhancing their performance and longevity in automotive environments.

- Q: Can glass fiber textiles be used for making sports equipment?

- Yes, glass fiber textiles can be used for making sports equipment. Glass fiber textiles are lightweight, strong, and have excellent resistance to wear and tear. They can be used to reinforce various sporting equipment such as tennis rackets, hockey sticks, and bike frames, providing added strength and durability without compromising performance.

- Q: Can glass fiber textiles be cut with scissors?

- Yes, glass fiber textiles can be cut with scissors. Glass fiber textiles, also known as fiberglass fabrics, are made from fine strands of glass fibers woven together. While they are strong and durable, they can still be cut with scissors or other sharp cutting tools. However, it is important to note that the type and quality of scissors used may affect the ease and precision of the cut. It is recommended to use sharp and sturdy scissors specifically designed for cutting fabrics or fiberglass materials for the best results.

- Q: Are glass fiber textiles resistant to acids or alkalis?

- Glass fiber textiles are typically resistant to both acids and alkalis.

- Q: Are glass fiber textiles resistant to staining from food and beverages?

- Glass fiber textiles have a general resistance to staining caused by food and beverages. To manufacture glass fiber textiles, glass fibers are woven or knitted together to form a durable and strong fabric. This fabric's non-porous and smooth surface naturally prevents staining. Unlike other fabrics, glass fiber textiles do not easily absorb liquids, making it challenging for stains to penetrate the material. Additionally, a protective coating or finish is often applied to enhance their stain resistance. However, it is essential to acknowledge that no fabric can be entirely stain-proof, and certain highly pigmented food or drinks may temporarily leave marks on glass fiber textiles. To minimize potential staining, regular cleaning and maintenance following the manufacturer's instructions are recommended.

- Q: Can glass fiber textile be printed on?

- Yes, glass fiber textile can be printed on. The process of printing on glass fiber textile involves applying ink or dye onto the surface of the textile using various printing techniques such as screen printing, digital printing, or heat transfer printing. However, it is important to note that due to the smooth and non-absorbent nature of glass fiber, special inks or dyes and printing techniques may be required for successful printing. These specialized materials and techniques ensure proper adhesion and long-lasting prints on glass fiber textiles.

- Q: Can glass fiber textiles be used in packaging?

- Yes, glass fiber textiles can be used in packaging. Glass fiber textiles are highly durable and have excellent strength properties, making them suitable for various packaging applications. They are commonly used in the manufacturing of protective packaging materials such as bags, wraps, and containers. Glass fiber textiles provide a high level of protection to the packaged goods, as they resist tearing, abrasion, and puncture. Additionally, they are resistant to moisture, chemicals, and UV radiation, making them ideal for packaging products that require a high level of protection during storage or transportation. Overall, glass fiber textiles offer a reliable and effective solution for packaging needs.

- Q: Can glass fiber textile be used in surgical gowns?

- Yes, glass fiber textile can be used in surgical gowns. Glass fiber textiles are known for their high strength, durability, and resistance to chemicals, making them an ideal choice for applications that require protection against fluids and contaminants, such as surgical gowns. These textiles can provide a barrier against bacteria and other microorganisms, ensuring a safe and sterile environment for both patients and healthcare professionals. Additionally, glass fiber textiles are lightweight and breathable, allowing for comfortable wear during long surgical procedures. However, it is important to note that glass fibers can be irritating to the skin, so proper precautions should be taken to minimize direct contact with the wearer's body.

- Q: Are glass fiber textiles resistant to fading?

- Yes, glass fiber textiles are resistant to fading. Glass fibers are made of inorganic materials, such as silica, which are highly resistant to UV radiation and sunlight exposure. Unlike organic fibers like cotton or polyester, glass fibers do not undergo chemical reactions that cause fading or discoloration. This makes glass fiber textiles highly durable and long-lasting, maintaining their color and appearance even after prolonged exposure to sunlight. Additionally, glass fibers are also resistant to other environmental factors like moisture, heat, and chemicals, further adding to their fade-resistant properties.

Send your message to us

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords