Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | (Mainland) | Brand Name: | |

| Model Number: | 1000 | coating: | alumina foil/glass fiber cloth | Dimension: | 1000*500*10/20/30/40/50 mm |

| Density: | 300kg/m3 |

Packaging & Delivery

| Packaging Details: | wooden box |

| Delivery Detail: | 15 days after receipt of pre-payment |

Specifications

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material

Introduction for Micropore Insulation Board ,Heat Insulation materials

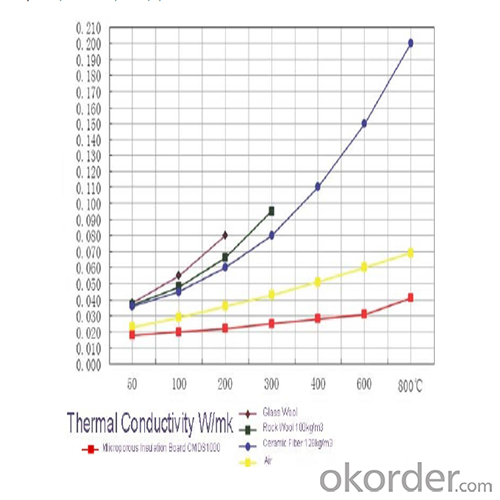

With heat-resistant inorganic fiber as reinforcing material combined with binders, NATI nanometer micro-heat conduction material is made of nanometer porous high-temperature resistant material and functional material with heat shield function through the combination of nanotechnology and special techniques. It has extremely low thermal conductivity that is just as one forth to one tenth that of ceramic fibre thermal insulation material.

Characteristics:

*High temperature resistance.

*Low thermal conductivity.

*Eco-friendliness and safety.

*Low thermal storage.

*Long service life.

Typical Application:

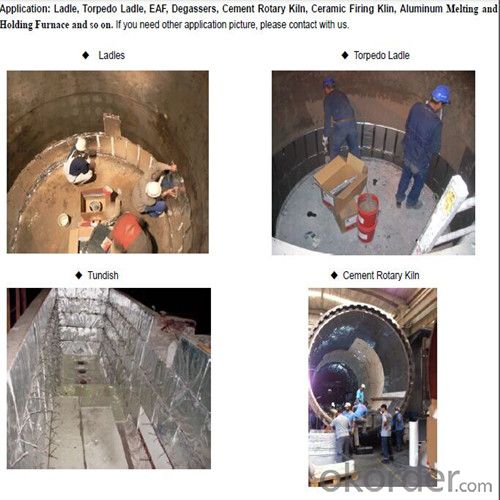

*It is widely used in various industries such as steel, petrochemical

Chemical & Physical Data:

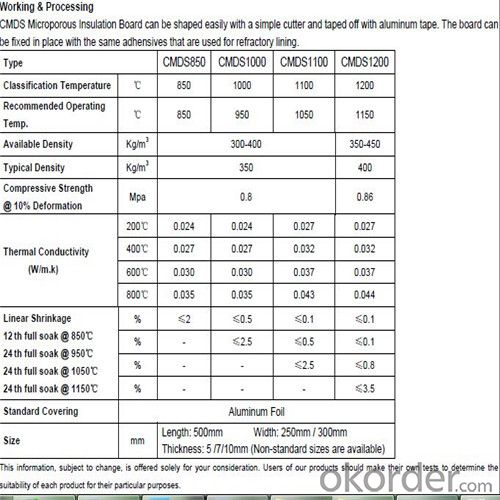

Type | 1000 NATI Micropore Board |

Bulk Density (kg/m3) | 300-350 |

Pressure Strength (MPa) | 0.7 |

Permament Linear Shrinkage %(800℃×6 hour) | 3.5% |

Thermal Conductivity (W/m.K) | 0.020(at 100 ℃) |

0.025(at 200 ℃) | |

0.028(at 400 ℃) | |

0.032(at 600 ℃) | |

0.037(at 800 ℃) |

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Are microfiber fabrics priced per square gram, or are other prices heavier and higher? Where is the factory specializing in the last microfiber fabric?

- Glass fiber reinforced plastic is a new type of composite material developed in early twentieth Century. It has many advantages, such as light weight, high strength, anticorrosion, heat preservation, insulation, sound insulation and so on. FRP doors and windows with glass fiber roving and its fabric as reinforcing material, using unsaturated resin as matrix material, through a special process to compound the two kinds of materials, and add other mineral filler, and then cured by heating, extruding into various hollow sections and different processing section. Specifically, the main features of FRP doors and windows are: anti-aging, high strength. The hollow section of the glass fiber reinforced plastic section is not lined with steel plates as an inner lining, and does not need any single material auxiliary reinforcement, and the structure is completely supported by the support of the structure itself. Due to the glass fiber and its fabric as reinforcing material, without filament resin bonding bare, by mechanical thermal curing pultrusion molding, so the bending and bending and deformation. Corrosion resistance and long service life.

- Q: Can glass fiber textiles be used in air ducts?

- Yes, glass fiber textiles can be used in air ducts. They are commonly used as insulation materials due to their high thermal resistance and fire resistance properties. The glass fiber textiles help in preventing heat transfer and maintaining the temperature inside the ducts. Additionally, they also provide soundproofing and improve the energy efficiency of the system.

- Q: Are glass fiber textiles resistant to fading and discoloration?

- Yes, glass fiber textiles are highly resistant to fading and discoloration.

- Q: What are the advantages of using glass fiber textile in composites?

- Glass fiber textiles offer numerous benefits when used in composites: 1. Exceptional strength: Glass fibers possess a remarkable strength-to-weight ratio, making them suitable for applications requiring durability and strength. 2. Enhanced lightweight properties: Glass fiber textiles are lightweight, contributing to a reduction in overall composite material weight. This advantage is particularly valuable in industries like aerospace and automotive, where weight reduction impacts fuel efficiency and performance. 3. Resistance to corrosion: Glass fibers exhibit high resistance to corrosion and do not react with chemicals or moisture. This quality makes them ideal for use in harsh environments, such as marine, chemical, or oil and gas industries, where corrosion resistance is crucial. 4. Excellent electrical insulation: Glass fibers possess superior electrical insulation properties, making them an excellent choice for applications where minimizing electrical conductivity is necessary. Industries like electronics and telecommunications greatly benefit from this feature. 5. Chemical resistance: Glass fibers are resistant to most chemicals, acids, and alkalis, making them suitable for applications involving exposure to harsh chemicals or corrosive substances. 6. Flexibility in design: Glass fiber textiles can be easily molded into complex shapes, enabling the creation of intricate designs and structures. This design flexibility offers engineers and designers greater freedom when developing composite components. 7. Cost-effectiveness: Glass fiber textiles are relatively inexpensive compared to other reinforcement materials, such as carbon fiber. This affordability makes them a cost-effective option for applications requiring high strength and durability, even in the presence of budget constraints. Overall, the advantages of using glass fiber textiles in composites encompass their high strength, lightweight nature, corrosion resistance, electrical insulation properties, chemical resistance, design flexibility, and cost-effectiveness. These properties have established glass fiber textiles as a preferred choice within various industries, including construction, automotive, aerospace, and electronics.

- Q: Can glass fiber textile be used in medical applications?

- Yes, glass fiber textile can be used in medical applications. It is commonly used in the manufacturing of medical devices such as wound dressings, surgical gowns, and orthopedic casts. The high strength and durability of glass fiber make it suitable for these applications, providing support and protection to patients. Additionally, glass fiber textiles can also be sterilized easily, making them a hygienic choice for medical use.

- Q: If people inhale air with glass fiber for a long time, what will happen to people? What kind of symptoms will people appear?

- Long term exposure to glass fiber hazardsWill cause people to feel, skin itching and other symptoms, glass fiber workers have contact dermatitis, but some workers can gradually tolerance, known as "hardening" phenomenon. The extent of skin damage depends on fiber diameter and surface roughness. It is now accepted that fiber diameter exceeds 5 mu m, which has a significant stimulating effect. A small number of people exposed to glass fiber and rock wool have skin allergies, but so far they have not been proved to be allergens. Eye and mucous membrane endanger: the worker that contacts glass fiber and so on can suffer conjunctivitis and keratitis, serious person can see the cornea is cloudy and local abscess. From the patient's eyes, a fiber less than 3 m in diameter can be developed. Pathological examination of the eyeball showed that the proliferation of corneal epithelial cells and the increase of mucin content in the conjunctiva showed mechanical stimulation. Similar pathological changes were confirmed by animal experiments. That is to say, there will not be immediate harm, but there will be a potential crisis for the body for a long time.

- Q: Can glass fiber textile be used in solar panel applications?

- Yes, glass fiber textile can be used in solar panel applications. It is commonly used as a reinforcing material for the backsheet of solar panels, providing mechanical strength and durability to protect the solar cells. Additionally, glass fiber textiles can also be used in the fabrication of flexible or lightweight solar panels, offering flexibility and ease of installation.

- Q: Can glass fiber textiles be used in filtration?

- Glass fiber textiles have the capability to be used in filtration. Renowned for their resistance to high temperatures, chemicals, and impressive filtration properties, glass fiber textiles possess a vast surface area and a delicate pore structure that enables them to efficiently capture and eliminate particles from both liquids and gases. These textiles are extensively utilized in a range of filtration applications, including air filters, water filters, and industrial filtration systems. Notably, they excel at removing minute particles such as dust, pollen, bacteria, and other impurities. Furthermore, glass fiber textiles can be effortlessly cleaned and reused, rendering them an economical and environmentally friendly choice for filtration purposes.

- Q: Are glass fiber textiles resistant to UV radiation?

- Yes, glass fiber textiles are generally resistant to UV radiation. The inherent properties of glass fibers make them highly resistant to degradation caused by exposure to UV rays.

- Q: Are glass fiber textiles suitable for marine applications?

- Yes, glass fiber textiles are suitable for marine applications. They possess excellent resistance to water, chemicals, and UV radiation, making them highly durable and long-lasting in marine environments. Additionally, they have good mechanical properties and can provide strength and reinforcement to various marine structures such as boats, yachts, and offshore platforms. Glass fiber textiles are also lightweight, easy to mold, and have low thermal expansion, making them preferable for marine applications.

Send your message to us

Glass Fiber Textile Micropore Insulation Board - Heat Insulation Materials

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords