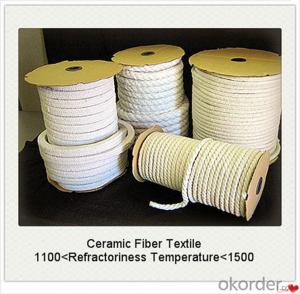

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Ceramic fiber cloth

2.1260C

3.thickness:1-5mm

4.reasonable price

High temperature ceramic fiber refractory fabric for heat insulation

Specifications:

Temperature:450C-1260C

Thickness:1.5mm-6.0mm

Width:500mm-1200mm

Density:500kg+/-30kg/m

Reinforcing materials: glass fiber wire, stainless steel wire

1. Products Details:

Hitex Ceramic Fiber Cloth is a woven fabric made from our high quality ceramic fiber woven yarn. The cloth is reinforced with fiberglass filament, or optional Inconel/alloy steel wire reinforcement. It is featured with heat insulation and high temperature protective materials in all kind of thermal installations and heat-conducting systems, widely used in welding, foundry works, aluminum and steel mills, boiler insulation and seal, shipyards, refineries, power plants and chemical plants.

2. Product Advantages:

1.Resistance to high temperature and chemical erosion

2.High mechanical strength

3.Low thermal conductivity

4.Low thermal storage

5.Resistance to heat shock

6.Easy installation

3. Technical Data:

Item | Ceramic Fiber Cloth | |

Classification Temperature | 1260C | 1260C |

Work Temperature | 450C | 1000C |

Basic Material | Fiberglass Reinforced | Stainless Steel Reinforced |

Theoretical Density ( kg/ m3) | 500±15 | |

Moisture Content (%) | ≤2 | |

Warp Density | 48~60 Piece/10cm | |

Weft Density | 21~30 Piece/10cm | |

Organic Content (%) | ≤15 | |

Specification (mm) | L:30,000mm / W:1,000mm / T:2~3mm | |

Packing | Plastic bag inside, woven bag outside | |

- Q: Can glass fiber textiles be used in the automotive industry?

- Yes, glass fiber textiles can be used in the automotive industry. Glass fiber textiles offer several advantages such as high strength, light weight, and resistance to heat and chemicals, making them suitable for various applications in automotive manufacturing, including interior components, upholstery, insulation, and reinforcement in composites for body parts.

- Q: Are glass fiber textiles resistant to mildew growth?

- Yes, glass fiber textiles are highly resistant to mildew growth. Unlike natural fibers such as cotton or wool, glass fiber textiles do not provide a suitable environment for mildew to grow. Glass fibers are inorganic materials that do not absorb moisture, which is essential for mildew growth. Additionally, glass fiber textiles are often treated with anti-microbial agents during the manufacturing process to further enhance their resistance to mildew. Therefore, if you are looking for a textile material that is resistant to mildew, glass fiber textiles are a great choice.

- Q: Can glass fiber textile be used in solar panels?

- Yes, glass fiber textile can be used in solar panels. Glass fiber textile is a lightweight and flexible material that possesses excellent electrical insulation properties. It can be used as a substrate or backing material in solar panels to provide structural support and protection to the delicate solar cells. The use of glass fiber textile in solar panels helps to enhance their durability, as it offers resistance to weathering, moisture, and UV radiation. Additionally, the flexibility of glass fiber textile allows for easier integration into various solar panel designs, enabling greater flexibility in installation options. Therefore, glass fiber textile is a suitable material for use in solar panels and contributes to their overall efficiency and longevity.

- Q: Are glass fiber textiles resistant to staining or discoloration from food or beverages?

- Yes, glass fiber textiles are generally resistant to staining or discoloration from food or beverages. Glass fibers are non-absorbent and do not retain liquids, which makes them less prone to staining compared to other textile materials. Additionally, glass fibers are often treated with special coatings or finishes that further enhance their resistance to staining and discoloration. However, it is important to note that prolonged exposure to certain highly pigmented or acidic substances may still cause some level of staining or discoloration on glass fiber textiles. It is always recommended to clean any spills or stains promptly to maintain the overall appearance and longevity of the fabric.

- Q: Can glass fiber textiles be used in shipbuilding?

- Yes, glass fiber textiles can be used in shipbuilding. They are commonly used as reinforcement materials in the construction of hulls, decks, and other structural components of ships. Glass fiber textiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for shipbuilding applications.

- Q: Can glass fiber textiles be used for insulation in buildings?

- Glass fiber textiles are a great choice for insulating buildings. They have excellent thermal and acoustic properties, making them popular for insulation. They are made from fine strands of glass that are woven into fabric or formed into mats or boards. These textiles are lightweight, flexible, and easy to install, making them suitable for many building applications. Glass fiber textiles are very effective at reducing heat loss or gain through walls, floors, and roofs. They can help maintain a comfortable indoor temperature, reduce energy consumption, and lower heating and cooling costs. They also absorb sound well, which can create a peaceful environment in buildings. One advantage of using glass fiber textiles for insulation is that they do not burn, unlike some other materials. This makes them a safe choice for building applications. They are also resistant to mold, mildew, and pests, which ensures a healthier indoor environment. Glass fiber textiles come in different forms, such as blankets, batts, rolls, and loose-fill, allowing for easy installation in various building components. They can be used in walls, ceilings, floors, and attics, providing insulation throughout the entire building. In conclusion, glass fiber textiles are a versatile and effective option for insulation in buildings. Their thermal performance, sound absorption capabilities, fire resistance, and ease of installation make them a popular choice for residential and commercial construction projects.

- Q: Are glass fiber textiles resistant to humidity?

- Indeed, glass fiber textiles exhibit resistance to humidity. Originating from molten glass, the fibers are skillfully spun into delicate strands, yielding a substance that possesses an innate quality of non-absorbency and moisture resistance. Consequently, glass fiber textiles showcase a remarkable ability to endure humidity, averting any dampness or water absorption. Furthermore, these textiles remain impervious to decay or deterioration when subjected to moisture, rendering them an exceptionally robust and enduring material suitable for humid surroundings.

- Q: Can glass fiber textile be used in solar panel applications?

- Indeed, solar panel applications can utilize glass fiber textile. With their lightweight nature, flexibility, and impressive thermal and electrical insulation properties, glass fiber textiles prove to be ideal substrate materials for solar panels. Acting as a backing material, glass fiber textiles not only provide structural support but also offer protection for solar cells. Furthermore, they can be combined with other materials through lamination to enhance the durability and performance of the solar panels. In conclusion, glass fiber textiles provide a cost-effective and environmentally friendly solution for incorporating solar panels into a wide range of applications.

- Q: I am producing 04 cloth of glass fiber. I want to know how to sell it

- There are five basic types: plain weave plan (similar cloth), twill (general +-45) twill and satin statin (similar to leno (unidirectional cloth), rib glass fiber mesh cloth weaving and basket matts (main) Oxford Brazzaville). Sales generally go for themselves

- Q: Can glass fiber textile be used in printed circuit boards?

- Yes, glass fiber textile can be used in printed circuit boards (PCBs). Glass fiber is commonly used as the substrate material in PCBs due to its excellent electrical insulation properties, high temperature resistance, and mechanical strength. It provides a stable and reliable platform for mounting and interconnecting electronic components. The glass fibers are impregnated with resin, typically epoxy, to form a composite material that can be easily processed into a PCB. The resin also helps to ensure the adhesion of copper layers and protect the circuitry from environmental factors. Overall, glass fiber textile is a widely accepted and commonly used material in the manufacturing of PCBs.

Send your message to us

High Temperature Ceramic Fiber Glass Fiber Textiles for Heat Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords