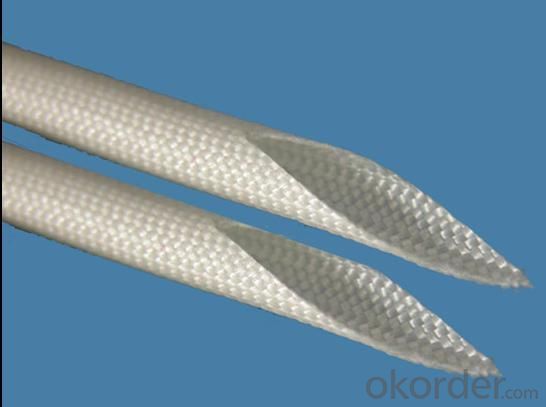

Glass Fiber Textile Textured Fiberglass Sleeving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

general infomation of Textured Fiberglass Sleeving

Textured fiberglass sleeving is braided by the textured fiberglass yarn without core. It can be used as fire protection of cable or wire covering.

Characteristics of Fiberglass Sleeving

Cost-efficient high temperature performance

Texturized Fiberglass Sleeve is a heavy wall braided glass fiber sleeve capable of operating at a continuous temperature of 1000F (538C). High bulk fiber construction gives excellent insulation properties, and the texturized, untreated construction allows Thermosleeve to exhibit excellent dielectric strength and resistance to thermal conductivity.

specification of Textured Fiberglass Sleeving

Inner diameter: 13mm-75mm (1/2"-3")

Thickness: 1.5mm-3mm (3/50"-1/8")

- Q: How do glass fiber textiles affect the breathability of fabrics?

- Glass fiber textiles can significantly affect the breathability of fabrics. When incorporated into fabrics, glass fibers tend to reduce the breathability due to their non-porous nature. Glass fibers are tightly woven or knitted, resulting in a dense fabric structure that limits air circulation. This restricts the movement of air and moisture through the fabric, making it less breathable. Additionally, glass fiber textiles often have a smooth surface, which further hampers breathability. This smooth surface prevents air from easily passing through the fabric, creating a barrier that reduces ventilation and airflow. However, it is important to note that the impact on breathability varies depending on the specific composition and construction of the fabric. Some fabrics may have a lower concentration of glass fibers or different weaving techniques that allow for better air permeability. Manufacturers may also employ special treatments or finishes to enhance breathability in glass fiber fabrics. Overall, the presence of glass fiber textiles in fabrics can generally diminish breathability. This factor should be considered when selecting fabrics for applications where breathability is a crucial requirement, such as in sportswear, outdoor clothing, or bedding.

- Q: Can glass fiber textiles be used in automotive seat covers?

- Glass fiber textiles, renowned for their remarkable strength, durability, and ability to withstand high temperatures, can indeed be employed in automotive seat covers. These textiles are well-suited for automotive purposes due to their exceptional insulation properties and resistance to both chemicals and UV radiation. Moreover, they can offer additional comfort and support to users by incorporating breathability and moisture-wicking features. In summary, the utilization of glass fiber textiles in automotive seat covers presents an opportunity for automotive manufacturers to enhance the seats' longevity and performance, rendering them a practical choice.

- Q: What are the properties of glass fiber textile?

- Glass fiber textiles are lightweight, durable, and have high tensile strength. They are also resistant to heat, moisture, chemicals, and UV radiation. Additionally, glass fiber textiles provide excellent insulation and are non-flammable, making them suitable for various applications such as reinforcement in composite materials, insulation in buildings, and as a protective layer in electronics.

- Q: How do glass fiber textiles resist mildew?

- Glass fiber textiles resist mildew due to their inherent properties. Glass fibers are inorganic materials that do not provide a suitable environment for the growth of mold or mildew. Unlike organic materials like cotton or wool, glass fibers do not contain nutrients that support the growth of microorganisms. Additionally, glass fibers are resistant to moisture absorption, which is crucial in preventing the development of mildew. The smooth surface of glass fibers also makes it difficult for mold spores to attach and grow. Furthermore, glass fiber textiles are often treated with anti-microbial agents during the manufacturing process to enhance their resistance to mildew. These agents create a barrier that inhibits the growth of mold and mildew, ensuring the longevity and hygienic properties of the textile. Overall, the combination of inorganic composition, moisture resistance, smooth surface, and anti-microbial treatment make glass fiber textiles highly resistant to mildew.

- Q: Are glass fiber textiles resistant to humidity?

- Indeed, glass fiber textiles exhibit resistance to humidity. Originating from molten glass, the fibers are skillfully spun into delicate strands, yielding a substance that possesses an innate quality of non-absorbency and moisture resistance. Consequently, glass fiber textiles showcase a remarkable ability to endure humidity, averting any dampness or water absorption. Furthermore, these textiles remain impervious to decay or deterioration when subjected to moisture, rendering them an exceptionally robust and enduring material suitable for humid surroundings.

- Q: What are the different bonding methods for glass fiber textile?

- Glass fiber textile can be bonded using various methods, each offering unique benefits and applications. 1. Adhesive bonding: In this approach, a specific adhesive is applied to the fabric and then cured to create a robust bond. Adhesive bonding is commonly employed in industries requiring flexibility and strength, such as sports equipment or automotive part manufacturing. 2. Heat bonding: Also known as thermal bonding, this method involves melting the fibers together using heat, resulting in a solid bond. Heat bonding is often used to join multiple layers of glass fiber fabric, creating a thicker and stronger material. It finds extensive use in the production of laminated glass fiber composites. 3. Stitch bonding: This technique employs stitching or sewing to bond the glass fibers. A needle and thread are used to sew the fibers together, creating a durable and sturdy bond. Stitch bonding is frequently utilized in applications where flexibility and breathability are essential, like clothing or upholstery manufacturing. 4. Weaving: This method interlaces the glass fibers, forming a fabric. The fibers are woven using a loom, crossing over and under each other to create a stable structure. Weaving is commonly employed in producing glass fiber textiles like fiberglass cloth or fiberglass tape. 5. Knitting: This technique involves interlocking loops of glass fibers to create a fabric. Knitting machines or hand knitting needles are used to form the loops, which are then secured together to produce a cohesive material. Knitting is often preferred for glass fiber garments or accessories due to its stretchiness and comfort. In summary, the bonding method chosen for glass fiber textiles depends on the specific requirements of the application, such as strength, flexibility, or breathability. Each method has its own advantages and limitations, and manufacturers select the most suitable approach based on the desired properties of the final product.

- Q: I am producing 04 cloth of glass fiber. I want to know how to sell it

- Glass cloth is mainly used for the production of a variety of electrical insulation laminates, printed circuit boards, vehicle bodies, tanks, boats, mould etc.. Glass cloth is mainly used for the production of plastic packaging cloth, as well as for corrosion resistant occasions.

- Q: How do glass fiber textiles affect the drapability of fabrics?

- The drapability of fabrics can be significantly influenced by glass fiber textiles, also known as fiberglass textiles. When glass fibers are added to a fabric, it can increase its stiffness and rigidity, preventing it from naturally draping. This is because glass fibers, compared to commonly used natural or synthetic fibers in textiles, have a high tensile strength and are relatively inflexible. When glass fiber textiles are integrated into fabrics, they create a network of interlocking fibers that provide structure and stability to the material. This can be advantageous in certain applications, such as industrial or technical textiles, where a more rigid fabric is desired. However, in garments or home furnishings where drape and fluidity are important, the presence of glass fibers can be a disadvantage. The stiffness caused by glass fiber textiles can limit the movement and flow of the fabric, resulting in a less natural drape. Fabrics containing glass fibers may not hang as smoothly or gracefully as those without, and may appear more rigid when worn or used for drapery. Furthermore, the presence of glass fibers can alter the feel and texture of the fabric, potentially making it less comfortable against the skin. It is important to note that the impact of glass fiber textiles on drapability can vary depending on the concentration and distribution of the fibers within the fabric. Higher concentrations of glass fibers or a more tightly woven or knitted structure generally have a more significant effect on drapability. Overall, although glass fiber textiles can offer advantages in terms of strength and stability, they can negatively affect the drapability of fabrics. Designers and manufacturers should carefully consider the intended application and desired characteristics of a fabric before deciding whether to incorporate glass fibers or explore other alternatives.

- Q: How does glass fiber textile contribute to weight reduction in products?

- Glass fiber textile contributes to weight reduction in products due to its lightweight nature. Glass fiber is known for its high strength-to-weight ratio, meaning it can provide significant strength and stiffness while weighing considerably less compared to other materials. When incorporated into products, such as automobile parts or aircraft components, glass fiber textile helps to reduce their overall weight, leading to improved fuel efficiency, increased performance, and easier handling. The use of glass fiber textile also allows manufacturers to design products with thinner and lighter structures without compromising on strength, resulting in a more efficient and lightweight end product.

- Q: What are the different colors available for glass fiber textiles?

- Glass fiber textiles come in a variety of colors to accommodate different preferences and uses. Popular choices include white, black, gray, and beige, which are selected for their adaptability and ability to harmonize with various environments. Moreover, glass fiber textiles can be dyed or coated with various pigments to achieve specific shades such as blue, green, red, or yellow. These vivid colors are frequently employed for decorative purposes or to create an impact in architectural or interior design ventures. In conclusion, the range of color options for glass fiber textiles is extensive and can accommodate diverse aesthetic preferences and design demands.

Send your message to us

Glass Fiber Textile Textured Fiberglass Sleeving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords