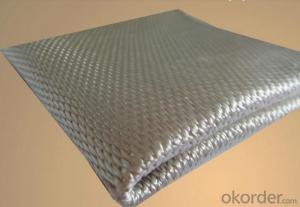

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Welding Pillow fiberglass fabric made

Welding pillow, fire resistance pillow, it is made of fiberglass

Description:

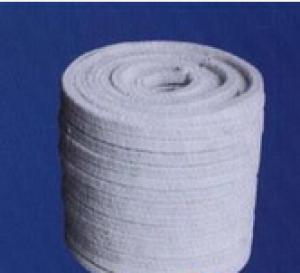

Welding pillow, fire resistance pillow, it is made of fiberglass and insert with glass wool or ceramic wool, sewing it into pillow, it is good welding products while need pillow shape fire resistance.

We can manufacture all kinds of welding pillor, fire resistance pillow as per customer request. Just contact our sales for details.

Outside Materials : fiberglass fabrics, Silica fabrics, heat treated fiberglass fabrics, silicone coated fiberglass fabrics, Ceramic fiber fabric, Carbonizedfiber fabrics, Aluminum coated fiberglass fabrics, Acrylic coated fiberglass fabrics.

Inside Materials: Glass fiber wool, ceramic fiber wool

Temperature resistance: 500 Deg. C . to 1000 Deg. C.

Size: as per customer request

- Q: How do glass fiber textiles resist shrinking?

- Glass fiber textiles resist shrinking due to their inherent properties. Glass fibers are made from molten glass, which is then rapidly cooled to form thin, flexible strands. These strands have a high resistance to heat, making them less susceptible to shrinking when exposed to high temperatures. Additionally, glass fibers have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with changes in temperature. This stability helps glass fiber textiles maintain their shape and size, preventing them from shrinking even under extreme conditions.

- Q: Can glass fiber textiles be used in furniture?

- Glass fiber textiles, or fiberglass, have a wide range of applications in furniture. This versatile material is lightweight, strong, and durable, making it an excellent choice for constructing furniture. Chairs, tables, and shelves can all benefit from the reinforcement and strength that fiberglass provides. Furthermore, the moldability of fiberglass allows for the creation of unique and innovative furniture designs. Its resistance to moisture, chemicals, and UV radiation also makes it suitable for both indoor and outdoor furniture. Combining fiberglass textiles with other materials, such as wood or metal, can create hybrid furniture pieces that offer the advantages of both materials. Overall, glass fiber textiles have numerous advantages that make them a viable option for furniture manufacturing.

- Q: Can glass fiber textile be used in aerospace structures?

- Yes, glass fiber textile can be used in aerospace structures. It offers high strength-to-weight ratio, good resistance to heat and chemicals, and excellent electrical insulation properties, making it suitable for various applications in aerospace engineering such as fuselage components, wing structures, and interior panels.

- Q: Can glass fiber textiles be used in reinforcement of sisal fibers?

- Yes, glass fiber textiles can be used in the reinforcement of sisal fibers. The combination of glass fiber textiles with sisal fibers can enhance the overall strength and durability of the composite material, making it suitable for various applications in industries such as automotive, construction, and aerospace.

- Q: Can glass fiber textiles be used in reinforcement of silk fibers?

- No, glass fiber textiles cannot be used in the reinforcement of silk fibers. Silk is a natural protein-based fiber, while glass fiber textiles are made from inorganic materials such as silica. The properties and behaviors of these two materials are vastly different, making it unsuitable for them to be used together in reinforcement.

- Q: Are glass fiber textiles biodegradable?

- No, glass fiber textiles are not biodegradable. Glass fibers are made from silica, which is a non-biodegradable material. This means that glass fiber textiles do not break down naturally over time and can persist in the environment for a long period. However, glass fibers can be recycled and reused, which helps to reduce their impact on the environment.

- Q: Is glass fiber textile waterproof?

- Glass fiber textile is not inherently waterproof. However, it can be made waterproof through the use of additional coatings or treatments. These coatings and treatments can help to repel water and prevent it from seeping through the fabric. Without these additional measures, glass fiber textile may absorb water and become wet. Therefore, if waterproofing is desired, it is important to ensure that the glass fiber textile is treated appropriately to make it water-resistant or waterproof.

- Q: Can glass fiber textiles be used for making hats or headwear?

- Yes, glass fiber textiles can be used for making hats or headwear. Glass fiber textiles, also known as fiberglass, are lightweight and durable materials that can be woven into a fabric-like form. They have excellent strength-to-weight ratio, making them suitable for various applications, including headwear. Fiberglass hats or headwear offer protection against impact, heat, or even electrical hazards. Additionally, fiberglass textiles can be coated or treated to enhance their resistance to chemicals, UV rays, or fire, providing added safety and durability. However, it is essential to note that fiberglass can be irritating to the skin if not properly encapsulated, so it is crucial to ensure that the hats or headwear made from this material are designed with a comfortable lining or coating to prevent direct contact with the skin.

- Q: Can glass fiber textile be used in insulation?

- Indeed, insulation can make use of glass fiber textile. Glass fibers are renowned for their exceptional thermal insulation characteristics, possessing both low thermal conductivity and a high resistance to heat transfer. In numerous insulation formats including blankets, batts, and boards, glass fiber textiles are frequently employed to deliver efficient thermal insulation solutions for buildings, industrial equipment, and pipelines. By weaving or bonding the fibers together, a textile material is formed, enabling the entrapment of air pockets and reduction of heat flow. Moreover, glass fiber textiles are lightweight, flexible, and impervious to moisture, rendering them an optimal selection for insulation purposes.

- Q: Can glass fiber textile be used in furniture?

- Yes, glass fiber textile can be used in furniture. It is a versatile material that offers several benefits such as strength, durability, and resistance to heat and moisture. Glass fiber textile can be used in various furniture components like upholstery, cushions, and reinforcement structures, providing added support and longevity to the furniture.

Send your message to us

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords