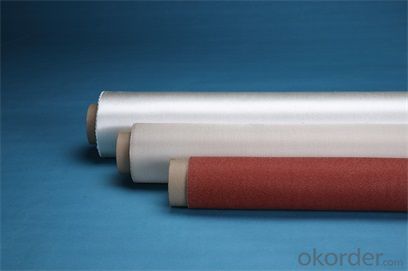

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Silica fiberglass is inorganic fiber that contents more than 96% of SiO2, it's resistant to high temperature, soft point 1700°C, long term service temperature 900 °C, it can work 10 minites at 1450 °C and keeps good state at 1600 °C for 15 seconds. For it's properties of chemical stability, high temperature resistance and ablation resistance, it widely used in aviationand aerospace, metallurgy, chemical, building material and fire fighting industry, etc.

Our factory is the only one that specialized manufacture silica fiberglass in China and has the production line of the whole process from marble making, fiber forming, weaving, and finish. The strength of silica fiberglass made from Na2O-B2O3-SiO2 system glass is 3-5 times higher than that from E glass. The products sold to more than 20 provinces, cities, autonomous regions and exported to foreign countries.

Silica fiberglass products are available in forms of needled mat, fabric, scrim, staple yarn, chopped strand and cord, etc.

Product Properties

1> SiO2>=96%

2> soft point nearly 1700°C, long-time working at 900°C

3> low thermal conductivity

4> good chemical stability

5> good electrical insulation

6> low thermal shrinkage

7> Non-asbestos product without pollution

8> good process performance

Product Uses

High temperature resistant, insulation and sealing material

High temperature ablation resistant material

Fireproof material (for fireproof protective clothe, fireproof curtain, fire blanket)

Dust collecting in media of high temperature gas and filtration in media of high temperature liquid

Filter for molten metal

Distinguisher, insulation material, filtration of automobile and motorcycle

Protective material for welding

Electricity insulation material

- Q: Can glass fiber textiles be used in aerospace applications?

- Yes, glass fiber textiles can be used in aerospace applications. Glass fiber textiles have many desirable properties that make them suitable for use in aerospace. Firstly, glass fiber textiles have a high strength-to-weight ratio, which is crucial in aerospace applications where weight reduction is a priority. This allows for lighter and more fuel-efficient aircraft, which is highly beneficial in terms of performance and cost savings. Secondly, glass fiber textiles have excellent thermal properties. They can withstand high temperatures without losing their structural integrity, making them suitable for use in aerospace components that are exposed to extreme heat, such as engine parts and exhaust systems. Additionally, glass fiber textiles have good resistance to corrosion and chemicals, which is important in aerospace applications where the materials are subjected to harsh environments, such as high altitude and exposure to various fluids and fuels. Furthermore, glass fiber textiles have good electrical insulation properties, which is crucial in aerospace applications where electrical conductivity can interfere with the performance of electronic systems. Moreover, glass fiber textiles are highly versatile and can be woven into different forms, such as fabrics, mats, and tapes, making them suitable for a wide range of aerospace applications, including structural components, insulation, and composite materials. Overall, glass fiber textiles are a viable option for aerospace applications due to their high strength-to-weight ratio, excellent thermal properties, resistance to corrosion and chemicals, electrical insulation properties, and versatility in form.

- Q: What are the challenges in manufacturing glass fiber textile?

- Some challenges in manufacturing glass fiber textile include maintaining consistent fiber quality, ensuring proper fiber alignment during weaving or knitting, managing the high heat and energy requirements for melting and drawing the glass, controlling the thickness and density of the fiber, and minimizing breakage or damage during the manufacturing process. Additionally, the handling and disposal of glass fiber waste and the potential health risks associated with handling glass fibers also pose challenges in the manufacturing process.

- Q: How is glass fiber woven into fabrics?

- Glass fiber is woven into fabrics through a process called weaving, where individual glass fibers are interlaced together using specialized looms or machines. This weaving technique creates a strong and durable fabric that is commonly used in industries such as aerospace, automotive, and construction.

- Q: How does the fiber length affect the properties of glass fiber textiles?

- The properties of glass fiber textiles are impacted by the length of their fibers. To begin with, longer fiber lengths generally result in stronger and more durable textiles. This is because the longer fibers interlock and bond within the fabric, increasing its tensile strength and making it more resistant to tearing or breaking when under stress. Additionally, longer fibers provide better flexibility and improved drapability to the fabric. They can be woven or knitted into complex patterns with greater ease, allowing the textile to be shaped and molded as required. This is especially important for applications where the fabric needs to conform to different shapes or be used in structural components. Moreover, longer fiber lengths enhance the thermal and electrical conductivity of glass fiber textiles. They provide a larger surface area for heat or electricity to transfer through the fabric. This is advantageous in applications where thermal insulation or electrical conductivity is necessary. However, it is important to consider the limitations of longer fiber lengths. They can make the textile stiffer and less comfortable to wear, reducing its suitability for clothing or soft furnishings. The longer fibers can also increase the weight of the fabric, making it less suitable for lightweight or high-performance applications. In conclusion, the choice of fiber length is crucial in determining the strength, durability, flexibility, thermal conductivity, and electrical conductivity of glass fiber textiles. It should be carefully considered based on the desired properties and specific requirements of the application.

- Q: Who has a Chinese English translation about glass fiber?. About WORD3 pages will do

- Glass is a substance known for its brittleness. Interestingly, once the glass is heated after being drawn into a much thinner than a human hair fiber glass, it seems completely forget their own nature, be like synthetic fiber as soft and tough, even more than the stainless steel wire of the same thickness!So, what's the use of glass fiber?

- Q: Can glass fiber textiles be used in curtains or drapes?

- Curtains or drapes can indeed utilize glass fiber textiles. These textiles, also known as fiberglass fabrics, possess a lightweight nature and possess high tensile strength. They find common usage in a range of applications, including insulation, reinforcement, and filtration. When it comes to curtains or drapes, glass fiber textiles bring forth several advantages. To begin with, they possess fire-resistant properties, rendering them a secure option for window coverings. Glass fiber textiles have a high melting point and are not easily ignited, thereby minimizing the risk of accidents and promoting safety in residential or commercial spaces. Additionally, glass fiber textiles offer exceptional insulation capabilities. By reducing heat transfer through windows, they assist in maintaining a comfortable indoor temperature. This not only enhances comfort but also leads to energy savings by reducing the reliance on heating or cooling systems. Moreover, glass fiber textiles provide privacy and light control. They can be manufactured in various levels of opacity, enabling different degrees of light transmission. They can be employed to create sheer curtains, allowing for privacy while still permitting natural light to enter the room. Alternatively, they can be utilized in the creation of blackout curtains, effectively blocking out all light. Lastly, glass fiber textiles possess durability and longevity. They are resistant to wear and tear, making them suitable for curtains or drapes that are frequently opened and closed. Additionally, they exhibit resistance to mold and mildew, proving advantageous in humid environments. All in all, glass fiber textiles present a versatile and practical option for curtains or drapes. By combining safety, insulation, light control, and durability, they prove to be a suitable choice for both residential and commercial applications.

- Q: How durable are glass fiber textiles?

- Glass fiber textiles are known for their exceptional durability. The fibers themselves are made from glass, which is inherently strong and resistant to wear and tear. This makes glass fiber textiles highly durable and able to withstand various environmental conditions and physical stresses. Glass fiber textiles are also resistant to chemicals, abrasion, and UV radiation. They do not degrade easily when exposed to harsh chemicals or sunlight, making them suitable for use in outdoor applications. Additionally, glass fibers have a high melting point, which means they can withstand high temperatures without losing their structural integrity. Furthermore, glass fiber textiles have excellent tensile strength, meaning they can resist stretching and breaking under tension. This property makes them ideal for applications where strength and durability are important, such as in the construction industry for reinforcing concrete or in manufacturing composite materials. Overall, glass fiber textiles are known for their exceptional durability, making them a reliable choice for a wide range of applications that require strength, resistance to chemicals and UV radiation, and the ability to withstand various environmental conditions.

- Q: How do glass fiber textiles contribute to water repellency?

- Water repellency is achieved in glass fiber textiles through their inherent properties and the manufacturing process. To begin with, glass fiber textiles are composed of thin strands of glass that possess a natural hydrophobic nature, making them resistant to water and preventing easy moisture absorption. When these glass fibers are woven together to create textiles, the resulting fabric inherits their water-repellent characteristics. Additionally, during the manufacturing process, glass fiber textiles can undergo treatment with supplementary water-repellent coatings. These coatings serve to enhance the fabric's ability to repel water by either impregnating it with a hydrophobic substance or applying a protective layer onto its surface. The combination of the inherent hydrophobic properties of glass fibers and the incorporation of water-repellent coatings results in the high effectiveness of glass fiber textiles in repelling water. This quality proves particularly advantageous in various applications where water resistance is desired, such as outdoor clothing, tents, upholstery, and automotive interiors. All in all, the contribution of glass fiber textiles to water repellency can be attributed to their natural hydrophobic properties and the application of water-repellent coatings during the manufacturing process.

- Q: Can glass fiber textiles be used in automotive door panels?

- Yes, glass fiber textiles can be used in automotive door panels. Glass fiber textiles are strong, lightweight, and have excellent insulation properties, making them suitable for reinforcing and insulating door panels. Additionally, they can enhance the overall structural integrity of the door panel while reducing its weight, which can contribute to improved fuel efficiency and performance in vehicles.

- Q: Can glass fiber textile be used in packaging materials?

- Yes, glass fiber textile can be used in packaging materials. Glass fiber textile is a versatile material that offers a range of benefits such as high strength, durability, and resistance to heat and chemicals. These properties make it suitable for packaging applications where strength and protection are important factors. Glass fiber textile can be used as reinforcement in packaging materials such as corrugated boxes, paperboard containers, and plastic films to enhance their strength and tear resistance. It can also be used as a lining material for packaging to provide additional protection against moisture, chemicals, or other external factors. Furthermore, glass fiber textile can be used in composite packaging materials, where it is combined with other materials like plastics or resins to create a strong and lightweight packaging solution. This combination allows for the development of innovative packaging designs that offer superior protection and sustainability. In summary, glass fiber textile can be effectively utilized in various packaging materials to enhance their strength, durability, and protective properties. Its versatility and performance make it a valuable choice for packaging applications where reliability and protection are crucial.

Send your message to us

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords