Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

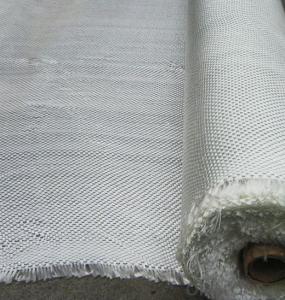

Fiberglass Fabric / Fiberglass Cloth / Fiberglass Rope / Fiberglass Tape

- Textured fiberglass textiles are composed of cloth, tape, twisted or braided rope etc.

- Having a maximum continuous operating temperature of 550℃.

Advantage of Textured Fiberglass Textiles

- Low thermal conductivity

- Electricity insulation

- Corrosive resistance

Application of Textured Fiberglass Textiles

Textured fiberglass textiles can be performed in process industries as fire curtains, gaskets or sealing in kiln, furnace and heaters etc. Application has been extended to the building industry as reinforcement material.

Size of Textured Fiberglass Cloth

Thickness:0.8mm-4mm (0.032"-0.157")

Width:800mm-1830mm (31.5"-72.05")

Size of Textured Fiberglass Tape

Thickness:0.8mm-6mm (0.032"-0.236)

Width:13mm-750mm(0.512"29.53")

Size of Textured Fiberglass Twisted Rope

Diameter.3mm-50mm(1/8"-2)

Size of Textured Fiberglass Round Rope

Diameter:4mm-50mm(4/25"-2")

Size of Textured Fiberglass Square Rope

Diameter:4mm-50mm(4/25"-2)

Photo of Fiberglass Texitle

- Q: How do glass fiber textiles absorb or repel moisture?

- Glass fiber textiles possess hydrophobic properties as they repel moisture. This is due to the non-porous nature of glass, preventing water absorption. The smooth surface of glass fibers lacks open spaces or pores for water molecules to enter. Consequently, when water contacts glass fiber textiles, it forms droplets that easily slide off the surface without absorption. Moreover, glass fiber textiles can undergo treatment with specialized coatings to enhance their hydrophobic characteristics. These coatings generate a thin layer on the fiber surface, further reducing moisture absorption. The coating molecules act as a barrier, repelling water and causing it to form droplets that roll off the fabric. It's important to note that although glass fiber textiles repel moisture, they are not entirely waterproof. Excessive water exposure or high pressure can enable water to penetrate the fabric through the gaps between the fibers. However, when compared to other natural or synthetic fibers, glass fiber textiles exhibit exceptional resistance to water absorption and can retain their properties even in wet conditions.

- Q: How is glass fiber woven into fabrics?

- Glass fiber is woven into fabrics through a process called weaving, where individual glass fibers are interlaced together using specialized looms or machines. This weaving technique creates a strong and durable fabric that is commonly used in industries such as aerospace, automotive, and construction.

- Q: Are glass fiber textiles biodegradable?

- No, glass fiber textiles are not biodegradable. Glass fibers are made from silica, which is a non-biodegradable material. This means that glass fiber textiles do not break down naturally over time and can persist in the environment for a long period. However, glass fibers can be recycled and reused, which helps to reduce their impact on the environment.

- Q: Can glass fiber textile be used in aerospace applications?

- Certainly, glass fiber textiles have the potential to be utilized in aerospace settings. Due to their lightweight nature, impressive mechanical properties, and inherent strength, they prove to be a fitting choice for diverse aerospace applications. These applications encompass the creation of aircraft elements including wings, fuselage, and interior components. In the realm of aerospace engineering, the resistance glass fiber textiles provide against elevated temperatures, corrosion, and impact is truly indispensable. Moreover, their low thermal conductivity renders them highly suitable for insulation functions. In conclusion, glass fiber textiles present an economical and effective resolution for aerospace purposes.

- Q: How do glass fiber textiles resist stretching?

- Glass fiber textiles resist stretching due to their unique composition and manufacturing process. Glass fibers are made by melting silica, which is the main component of glass, and then extruding the molten material into thin strands. These strands are then spun into yarns and woven or knitted into textiles. The resistance to stretching in glass fiber textiles comes from the inherent properties of glass itself. Glass is known for its rigidity and lack of elasticity, which means it does not easily deform under stress or strain. When glass fibers are woven or knitted into textiles, they create a strong and stable structure that resists stretching. Furthermore, glass fibers have a high tensile strength, which means they can withstand a significant amount of pulling force without breaking or elongating. This property is particularly useful in applications where strength and durability are important, such as in reinforcement materials for composites or in protective clothing. In addition to their composition, the manufacturing process of glass fiber textiles also contributes to their resistance to stretching. The fibers are tightly woven or knitted together, creating a dense and compact structure that prevents excessive stretching. The manufacturing process can also involve treatments such as heat setting or chemical coatings, which further enhance the textile's resistance to stretching. Overall, glass fiber textiles resist stretching due to the rigid and non-elastic nature of glass fibers, as well as the tight and compact structure created during the manufacturing process. These properties make glass fiber textiles an excellent choice for applications that require strength, durability, and dimensional stability.

- Q: How do glass fiber textiles perform in terms of UV resistance?

- Glass fiber textiles, known as fiberglass textiles, typically exhibit outstanding UV resistance. The inherent properties of glass fibers grant them a remarkable level of UV radiation resistance. Consequently, glass fiber textiles can endure prolonged exposure to sunlight without significant degradation or harm. The resistance to UV rays is of utmost importance for textiles, as these rays can lead to fading, discoloration, and weakening of the material over time. However, glass fibers possess a natural resistance to UV radiation due to their composition. Unlike organic fibers like cotton or polyester, glass fibers, being inorganic, are less prone to UV degradation. Glass fiber textiles find common application in scenarios where UV resistance plays a critical role, such as outdoor furniture, awnings, and sunshades. Additionally, they are extensively utilized in industries like construction and automotive, where exposure to sunlight is unavoidable. It is worth noting that although glass fiber textiles boast excellent UV resistance, their performance can still be affected by various factors, including the manufacturing process, the type of glass employed, and the presence of any protective coatings. Consequently, it is advisable to consult the manufacturer's specifications or conduct specific UV resistance tests to obtain accurate information regarding the UV resistance performance of a particular glass fiber textile.

- Q: Can glass fiber textiles be used in insulation tapes?

- Yes, glass fiber textiles can be used in insulation tapes. Glass fiber textiles are known for their excellent insulation properties and high resistance to heat and fire. These qualities make them ideal for use in insulation tapes, as they provide effective thermal insulation and help prevent heat transfer. Additionally, glass fiber textiles are durable and have good tensile strength, which ensures the longevity and reliability of insulation tapes.

- Q: Can glass fiber textile be woven?

- Glass fiber textile can indeed be woven. These textiles are formed by spinning thin strands of glass into yarn and subsequently interlacing them to produce a fabric. This weaving technique resembles that of cotton or silk fabrics. Glass fiber textiles are renowned for their exceptional toughness and longevity, rendering them appropriate for a wide range of uses including insulation, reinforcement, and protective garments.

- Q: Can glass fiber textiles be used in clothing?

- Yes, glass fiber textiles can be used in clothing.

- Q: Are glass fiber textiles resistant to moisture?

- Yes, glass fiber textiles are generally resistant to moisture. Glass fibers themselves are not affected by moisture or water, and they do not absorb water like other materials such as cotton or wool. This makes glass fiber textiles highly resistant to moisture and water damage. Additionally, glass fibers are commonly used in applications where moisture resistance is required, such as in outdoor fabrics, boat covers, and protective clothing. However, it is important to note that while the glass fibers themselves are resistant to moisture, the bonding agents or coatings used in glass fiber textiles may vary in their moisture resistance capabilities. Therefore, it is recommended to check the specific product specifications or consult the manufacturer to ensure the desired level of moisture resistance.

Send your message to us

Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords