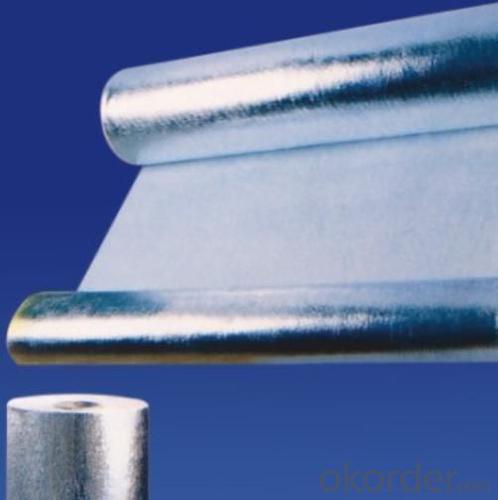

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info of E- Glass Fiber Fabric Laminated with Aluminum Foil

Dimension/Size

1). Roll width: 48mm, 58mm

2). Roll Length: 28m,

3). Core I. D.: 3"(76mm+/-1)

Packing:Regular Package

Standard:1000m*50m

Origin:China

Product Desciption

E- Glass Fiber Fabric Laminated with Aluminum Foil was made from aluminium Foil combine Fiberglass Mesh Fabric with polyethylene. As a hot stamping foil, It is used to intalled to ceiling by heat, Insulation Batts, Radiant Barriers, Covering Ducts and Pipes.

1. Intended to supply reflection but with lighter weight

Alumium Foil + Fiberglass Mesh Fabric + PE---thermal/heat/themol sensitive adhesive sheeting/facings/finish

2. Construction & Benefits:

Details of structure was list in table.

With fiberglass mesh cloth (25mesh, 31g/sqm ) as lining made this product light but strong enough.

Apply high reflective foil as exposed face, 18mircon thick supply stronger tensile strength.

Application of E- Glass Fiber Fabric Laminated with Aluminum Foil:

Widely used in wall/floor surface reinforcement in the building preventing from wall cracks and ceiling cracks and also barrier moisture / vapor / radiant / light in cover of roof, wall, pipe, air duct, glasswool, glass fiber mat as son on.

- Q: Please analyze the differences between the two fabrics. The more detailed, the better. Thank you

- Why is bamboo fiber towel antibacterial and bacteriostatic?The scientists found that the bamboo has a unique material, this material is named "bamboo Kun", has the anti mite deodorant pest control function of natural. The same number of bacteria under the microscope, bacteria can thrive in the cotton and wood fiber products, bamboo fiber products on the bacteria can not survive long time, and in the short term but also disappeared or reduced within 24 hours of bacterial mortality was above 73%. Effect of bamboo fiber fabrics with natural antibacterial and anti ultraviolet radiation in the sun, after repeated washing, can still ensure that its original features, without any adverse allergic reactions to human skin, and has the health care function of human skin. It has been widely used in masks, bandages, surgical gowns, nurses and other medical protective products and towels, socks, underwear, bedding and other skin care products.

- Q: Can glass fiber textile be used in oil and gas pipelines?

- Yes, glass fiber textile can be used in oil and gas pipelines. Glass fiber textiles are known for their high strength, corrosion resistance, and ability to withstand high temperatures, making them suitable for use in demanding environments such as oil and gas pipelines. They provide excellent insulation and are capable of withstanding the harsh conditions typically encountered in the oil and gas industry.

- Q: Can glass fiber textiles be used for reinforcement in metals?

- Yes, glass fiber textiles can be used for reinforcement in metals. Glass fiber textiles are commonly used as a reinforcing material in metal composites, such as fiber-reinforced polymers (FRPs). The strong and lightweight properties of glass fibers make them suitable for enhancing the mechanical properties and performance of metals, including increased strength, stiffness, and resistance to corrosion.

- Q: Can glass fiber textiles be used in military applications?

- Yes, glass fiber textiles can be used in military applications. Glass fiber textiles are known for their high strength and durability, making them suitable for various military uses. They can be used in the manufacturing of military uniforms, bulletproof vests, and other protective gear. Glass fiber textiles can provide excellent resistance to heat, flame, and chemicals, which is crucial in military environments. Additionally, glass fiber textiles can be used in the construction of military tents, camouflage nets, and other textile structures. Overall, glass fiber textiles offer numerous benefits and can be effectively utilized in various military applications.

- Q: Can glass fiber textiles be used in reinforcement of flax fibers?

- Yes, glass fiber textiles can be used in reinforcement of flax fibers. The combination of glass fiber textiles and flax fibers can enhance the mechanical properties of the composite material, making it stronger and more durable.

- Q: What are the properties of glass fiber textile?

- Glass fiber textiles are lightweight, durable, and have high tensile strength. They are also resistant to heat, moisture, chemicals, and UV radiation. Additionally, glass fiber textiles provide excellent insulation and are non-flammable, making them suitable for various applications such as reinforcement in composite materials, insulation in buildings, and as a protective layer in electronics.

- Q: What are the limitations of glass fiber textiles?

- Glass fiber textiles have several limitations that need to be considered before their usage. Firstly, glass fiber textiles are relatively brittle and can break easily under excessive stress or impact. This makes them less suitable for applications where flexibility and resistance to breakage are crucial. Secondly, glass fiber textiles have a relatively low resistance to heat. They can melt or deform when exposed to high temperatures, limiting their applications in environments with extreme heat conditions. Additionally, glass fiber textiles are not fire-resistant and may contribute to the spread of flames. Moreover, glass fiber textiles are susceptible to moisture absorption, which can lead to a reduction in their mechanical properties. This limits their use in outdoor applications or environments with high humidity levels, where moisture damage can compromise their integrity. Furthermore, glass fiber textiles can be challenging to work with due to their sharp and abrasive nature. They can cause skin irritation or respiratory issues when handled without proper protective equipment. This makes it necessary to take appropriate safety measures when working with glass fiber textiles. Lastly, glass fiber textiles are generally more expensive compared to other textile materials like cotton or polyester. This cost factor can be a limitation for applications where cost-effectiveness is crucial. Overall, while glass fiber textiles offer several advantages such as high strength and chemical resistance, their limitations in terms of brittleness, heat resistance, moisture absorption, handling challenges, and cost need to be carefully considered in order to make informed decisions about their usage.

- Q: Are glass fiber textiles resistant to humidity?

- Yes, glass fiber textiles are generally resistant to humidity. They do not absorb moisture easily and maintain their strength and integrity even in humid conditions.

- Q: How do glass fiber textiles contribute to chemical resistance?

- Glass fiber textiles contribute to chemical resistance due to the inherent properties of glass. Glass fibers are highly resistant to the corrosive effects of chemicals, acids, and alkalis, making them an excellent choice for applications where chemical resistance is required. The tightly woven structure of glass fiber textiles provides a barrier against chemical penetration, preventing damage and degradation to the underlying materials. Additionally, glass fibers do not absorb or react with most chemicals, making them highly durable and suitable for use in harsh chemical environments.

- Q: Is glass fiber textile hypoallergenic?

- Yes, glass fiber textile is hypoallergenic.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords