Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:The combination of laminating an aluminum metallic/film heat shield to a layer of protective fiberglass insulation protects personnel or equipment by reflecting radiant heat. The fabric have advantages of smooth and flat surface, high resistant, good tensile strength, airtight, watertight, good sealed performance, strong weather-ability, etc.

Features: High Reflectivity, Waterproof, Fire Resistant, Heat Resistant

Application: Thermal Insulation Jackets, Cover, Blanket, Mattress, Pad,Heat Shields, Thermal Barrier, Industrial Safety Apparel

PRICE: USD3.2 per square meter

UNIT: square meter

MOQ: 500 square meters

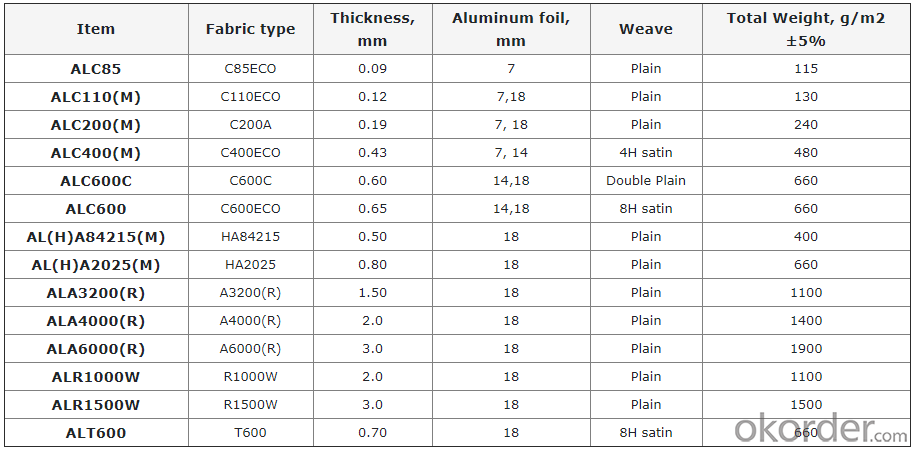

Weight: 220gsm-1200gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature:550℃

Product name: Aluminium Foil laminated fiberglass fabric

Coating/Finish/Surface Treatment: Aluminium Foil laminated

Roll length: 50 meter or customized

Color: silver grey

Weave Type: twill woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass fabric, Aluminium foil

Thickness: 0.2mm to 1.7mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Aluminium foil laminated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabric be used for heat-resistant gaskets?

- Yes, fiberglass fabric can be used for heat-resistant gaskets. Fiberglass fabric is known for its excellent heat resistance properties, making it a popular choice for applications that require resistance to high temperatures. It can withstand temperatures up to several hundred degrees Celsius without degrading or melting. This makes fiberglass fabric an ideal material for heat-resistant gaskets, as it can effectively seal joints and prevent heat transfer between different components. Additionally, fiberglass fabric is also resistant to chemicals, water, and abrasion, further enhancing its suitability for gasket applications.

- Q: What are the different colors available for fiberglass fabric rolls?

- The different colors available for fiberglass fabric rolls can vary, but some common options include white, black, gray, and various shades of blue, green, and yellow.

- Q: Large screen whole electric lift screen, PVC good or glass fiber?

- Look at the specific quality, glass fiber and PVC soft cloth are graded.

- Q: Can fiberglass fabric be used for heat-resistant curtains?

- Yes, fiberglass fabric can be used for heat-resistant curtains. Fiberglass is known for its excellent heat resistance properties, as it can withstand high temperatures without melting or burning. It is a common choice for applications that require fire resistance, such as curtains used in industrial settings or near fire hazards. Fiberglass fabric is non-combustible and can provide insulation against heat, making it a suitable material for curtains that need to withstand high temperatures.

- Q: Is fiberglass fabric resistant to UV degradation in outdoor applications?

- Yes, fiberglass fabric is highly resistant to UV degradation in outdoor applications. Fiberglass fabric is made from fibers that are manufactured to withstand prolonged exposure to sunlight and other environmental factors. The fabric is treated with special coatings or finishes that provide additional protection against UV radiation. This UV resistance makes fiberglass fabric an ideal choice for outdoor applications where exposure to sunlight is a concern, such as in awnings, canopies, and outdoor furniture. Additionally, fiberglass fabric maintains its strength and integrity even after years of exposure to UV rays, ensuring its long-lasting performance in outdoor settings.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- Fiberglass fabric is indeed suitable as insulation in steam systems. Its exceptional thermal insulation properties and ability to withstand high temperatures make it a favored option. By effectively capturing the steam's heat, it prevents any loss of heat and enhances energy efficiency in the system. Moreover, fiberglass fabric's lightweight, flexible, and effortless installation process make it a convenient choice for insulating steam pipes and equipment. Its non-combustible nature also ensures safety in steam systems. All in all, fiberglass fabric is a dependable and efficient insulation material for steam systems.

- Q: What are the different weights per square meter available for fiberglass fabric?

- The weights per square meter available for fiberglass fabric can vary depending on the specific application and intended use. However, common weights for fiberglass fabric range from 100 grams per square meter (gsm) to 900 gsm.

- Q: How is fiberglass fabric stored and handled?

- Fiberglass fabric should be stored and handled with care to maintain its quality and prevent any damage. When it comes to storage, it is recommended to keep the fabric in a cool, dry place to avoid exposure to moisture or extreme temperature fluctuations. Ideally, it should be stored in a sealed bag or container to protect it from dust, dirt, and any potential contaminants. When handling fiberglass fabric, it is important to wear protective gloves to prevent any irritation or skin reactions. Additionally, wearing safety goggles or a face shield is recommended to protect the eyes from any loose fibers. During transportation or handling, it is advisable to avoid any sharp objects or rough surfaces that can cause tears or abrasions to the fabric. Care should be taken to avoid any unnecessary bending or folding, as this can lead to permanent creases or weak spots in the material. If the fabric needs to be cut or trimmed, it is recommended to use sharp scissors or a utility knife to ensure clean and precise cuts. It is also advisable to work in a well-ventilated area or wear a dust mask to minimize the inhalation of any loose fibers. In summary, fiberglass fabric should be stored in a clean and dry environment, handled with protective gear, and protected from any potential damage during transportation or cutting. By following these guidelines, the lifespan and quality of the fiberglass fabric can be preserved.

- Q: How does the weave pattern affect the strength of fiberglass fabric?

- The strength of fiberglass fabric is greatly influenced by its weave pattern. This pattern refers to how the individual strands of fiberglass are intertwined during production. There are various commonly used weave patterns for fiberglass fabric, namely plain weave, twill weave, and satin weave. The plain weave pattern is the simplest and most widely used. It involves an alternating over-under pattern where each strand goes over and under the adjacent strands. This pattern provides good strength and stability in both the warp and weft directions, making it suitable for a wide range of applications. Twill weave, on the other hand, creates a diagonal pattern through the interlacing of strands. This pattern offers better drapability and flexibility compared to plain weave. It also provides enhanced strength and durability, especially in the direction of the diagonal weave. Twill weave is often employed in applications that require increased resistance against wear and tear. The satin weave pattern is the most intricate and complex. It involves strands that float over several adjacent strands before interlacing again. Satin weave produces a smooth and lustrous surface, making it ideal for applications that prioritize aesthetic finishes. However, it sacrifices some strength and stability when compared to plain or twill weaves. To summarize, the weave pattern significantly impacts the strength of fiberglass fabric. While plain weave offers overall strength, twill weave enhances durability and resistance to wear and tear. Satin weave sacrifices some strength for a smoother surface and improved aesthetics. The choice of weave pattern depends on the specific requirements of the application, taking into account factors such as strength, flexibility, and appearance.

- Q: Can fiberglass fabric be used for reinforcement in boat decks?

- Indeed, boat decks can benefit from the use of fiberglass fabric for reinforcement. Renowned for its robustness, longevity, and ability to withstand corrosion, fiberglass fabric proves itself as an ideal material for constructing boats. By incorporating fiberglass fabric, boat decks gain structural integrity, reinforcing their overall strength. Moreover, the lightweight nature of fiberglass fabric offers advantages such as improved buoyancy and enhanced fuel efficiency. Furthermore, its exceptional resistance to water and various weather conditions renders it perfectly suitable for marine environments. In summary, fiberglass fabric remains a favored option for reinforcing boat decks due to its strength, durability, resistance to corrosion, and lightweight attributes.

Send your message to us

Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords