Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

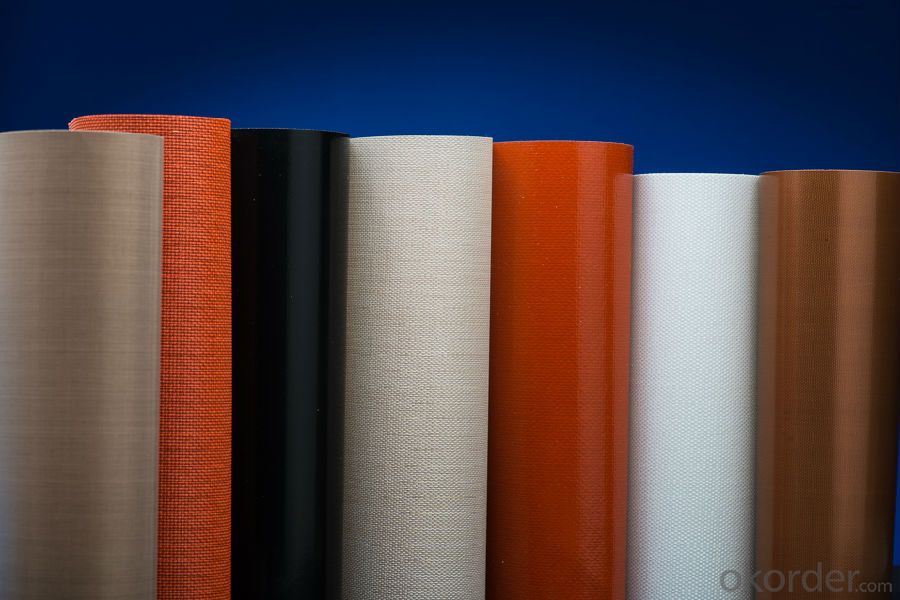

Coatecd Fiberglass Fabric with Different Specification

Fiberglass Fabric Description

Silicone coated fiberglass fabric are made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: How is fiberglass fabric used in the production of insulation jackets?

- Fiberglass fabric plays a crucial role in the production of insulation jackets. It is widely used as an outer layer material due to its exceptional thermal resistance, durability, and fire-retardant properties. Insulation jackets are designed to provide thermal insulation and protect various industrial equipment, pipelines, and machinery from extreme temperatures, moisture, and other environmental factors. When manufacturing insulation jackets, fiberglass fabric is typically employed as the outermost layer. This fabric is made from fine strands of glass that are woven together to form a strong and flexible textile. The structure of fiberglass fabric allows it to trap air between the fibers, creating a layer of insulation that helps to regulate temperature and prevent heat loss or gain. The fiberglass fabric used in insulation jackets is usually coated with a protective layer, such as silicone or acrylic, to enhance its resistance to chemicals, abrasion, and weathering. This coating also improves the fabric's ability to repel moisture, preventing condensation and potential damage to the insulation material. Insulation jackets made with fiberglass fabric offer several advantages. Firstly, fiberglass fabric is highly resistant to high temperatures, making it suitable for applications where insulation is required in hot environments. It can withstand temperatures ranging from -200°C to 540°C (-328°F to 1004°F), ensuring long-lasting protection for the equipment it covers. Secondly, fiberglass fabric is lightweight and flexible, allowing for easy installation and removal of the insulation jackets. Its flexibility enables it to conform to the shape of the equipment, ensuring a snug fit and optimal insulation performance. Furthermore, fiberglass fabric is known for its excellent fire resistance properties. It is inherently non-combustible and does not contribute to the spread of flames, making it a safe material to use in industrial settings. In summary, fiberglass fabric is a vital component in the production of insulation jackets. Its thermal resistance, durability, fire-retardant properties, and ability to repel moisture make it an ideal material for protecting industrial equipment from extreme temperatures and environmental factors.

- Q: Can fiberglass fabrics be used for reinforcement in composites?

- Yes, fiberglass fabrics can be used for reinforcement in composites.

- Q: Can fiberglass fabric be used for welding blankets?

- Yes, fiberglass fabric can be used for welding blankets. Fiberglass fabric is heat-resistant and has excellent fire-retardant properties, making it ideal for protecting against sparks, slag, and molten metal during welding operations. It can withstand high temperatures without melting or burning, providing a reliable barrier between the welding area and surrounding objects. Additionally, fiberglass fabric is lightweight and flexible, making it easy to handle and maneuver. Its durability and resistance to abrasion further enhance its suitability for welding blankets, ensuring long-lasting protection and safety in welding environments.

- Q: Can fiberglass fabric be used for filtration in water treatment plants?

- Yes, fiberglass fabric can be used for filtration in water treatment plants. It is commonly used as a filtration medium due to its high strength, durability, and resistance to chemicals. Additionally, fiberglass fabric has excellent filtration properties, effectively removing impurities and particles from water, making it an ideal choice for water treatment applications.

- Q: Can fiberglass fabric be used for making luggage?

- Yes, fiberglass fabric can be used for making luggage. It provides strength, durability, and lightweight properties, making it an ideal material for creating sturdy and long-lasting luggage.

- Q: How much glass fiber cloth and how much epoxy resin does it take to make a square meter of fiberglass?

- There is a construction personnel operation, proficient and skilled, professional and non professional will is much better. I suggest you try it yourself, it will be better.

- Q: Is fiberglass fabric resistant to chemicals used in pharmaceutical industry?

- Yes, fiberglass fabric is generally resistant to the chemicals used in the pharmaceutical industry. Its non-reactive nature and high chemical resistance make it suitable for use in various pharmaceutical applications such as filtration, insulation, and protective clothing. However, it is important to note that the specific chemical resistance may vary depending on the type of fiberglass fabric and the concentration and duration of exposure to the chemicals.

- Q: How is fiberglass fabric used in the production of boat hulls?

- Due to its exceptional strength, durability, and lightweight nature, fiberglass fabric finds extensive use in the production of boat hulls. This versatile material is created by weaving together fine strands of glass into a fabric, which is then impregnated with a resin, typically polyester or epoxy, to form a solid and rigid composite structure. When it comes to boat hull production, fiberglass fabric serves as a reinforcement material. It is commonly applied in multiple layers, known as laminate, to construct a robust and inflexible hull. The fabric is initially laid down on a mold or frame, taking the desired shape of the boat. Then, the resin is applied over the fabric, fully saturating it and creating a bond between the layers. Once the resin cures and hardens, the fiberglass fabric becomes an integral component of the boat hull. It provides structural integrity, rendering the hull resistant to impacts, flexing, and water damage. The strength of the fiberglass fabric ensures that the hull can withstand the stresses and forces encountered during boating, such as waves, wind, and collisions. Additionally, fiberglass fabric exhibits excellent resistance to corrosion, rot, and degradation caused by exposure to water, making it an ideal choice for boat hulls. It is also relatively easy to shape and mold, enabling boat manufacturers to create hulls of various designs and sizes. Furthermore, if the hull sustains any cracks or punctures, fiberglass fabric can be easily repaired. Simply applying a new layer of fiberglass fabric and resin over the damaged area ensures that the boat remains structurally sound and watertight. In conclusion, fiberglass fabric plays a crucial role in boat hull production by providing strength, durability, and resistance to water damage. Its versatility and ease of repair make it a preferred choice for boat manufacturers worldwide.

- Q: How does fiberglass fabric perform in terms of moisture absorption?

- Known for its exceptional resistance to moisture absorption, fiberglass fabric does not readily absorb water or moisture due to its non-porous and hydrophobic nature. This characteristic renders it highly suitable for situations where exposure to moisture or humidity is a concern. Moreover, the low moisture absorption of fiberglass fabric aids in preserving its structural integrity and dimensional stability, even in environments with elevated moisture levels. Consequently, fiberglass fabric's outstanding performance in terms of moisture absorption establishes it as a dependable choice across various industries and applications.

- Q: Are fiberglass fabrics suitable for use in the automotive industry?

- Indeed, the automotive industry finds fiberglass fabrics to be a fitting choice. These fabrics possess numerous advantages that render them ideal for automotive applications. Primarily, fiberglass fabrics are renowned for their robustness and endurance. They exhibit high tensile strength and resist wear and tear, thus enabling them to withstand the demanding conditions of the automotive environment. Moreover, fiberglass fabrics display remarkable resistance to chemicals, moisture, and extreme temperatures, thereby further augmenting their appropriateness for automotive utilization. Secondarily, fiberglass fabrics are lightweight, a pivotal characteristic in the automotive industry. This feature aids in enhancing fuel efficiency and overall vehicle performance. By employing fiberglass fabrics, manufacturers can diminish the weight of car components without compromising strength and safety. Furthermore, fiberglass fabrics possess exceptional thermal and electrical insulation properties, rendering them suitable for various automotive applications. They serve as insulation for engine compartments, exhaust systems, and electrical wiring, among other uses. Moreover, fiberglass fabrics can be molded into diverse shapes and sizes, enabling customization and versatility in automotive design. They seamlessly integrate into various components, including body panels, interior trims, and structural reinforcements. Conclusively, fiberglass fabrics offer a blend of strength, durability, lightweightness, insulation, and versatility, making them exceedingly suitable for the automotive industry. They contribute to improved vehicle performance, fuel efficiency, and safety, making them a favored choice among automotive manufacturers.

Send your message to us

Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords