Thermal Insulation High Temperature Carbon Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD12 per square meter

UNIT: square meter

MOQ: 500square meters

Width: 1m, 1.27m, 1.52m

Color: black

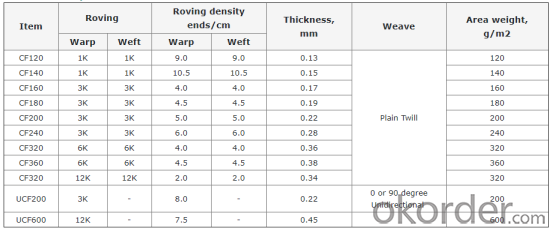

Weave Type:twill woven, plain woven

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Carbon fabric is woven by carbon fiber yarn available with 1K,3K,6K,12K, 24K. Carbon fiber is known as super high strength, modulus and light weight. It is a outstanding reinforce material. Depends on the various quality of carbon fiber, there are available various fabrics.

Features: High strength and modulus, Excellent resin and adhesive compatibility, Flexible customized specification

- Q:What are the different fiberglass fabric coatings for flame retardancy?

- Some common fiberglass fabric coatings for flame retardancy include silicone, acrylic, and polyurethane. These coatings are applied to the fabric to enhance its resistance to flames and prevent it from igniting or spreading fire.

- Q:What are the maintenance requirements of fiberglass fabric?

- The maintenance requirements of fiberglass fabric are relatively low compared to other materials. However, there are still a few things to keep in mind to ensure the longevity and optimal performance of fiberglass fabric. Firstly, regular cleaning is necessary to remove any dirt, dust, or debris that may accumulate on the surface of the fabric. This can be done by gently vacuuming or using a soft brush to remove loose particles. Avoid using harsh chemicals or abrasive cleaners, as they can potentially damage the fabric. In addition to cleaning, it is important to inspect the fabric periodically for any signs of wear or damage. Look for any fraying, tears, or loose threads, and address them promptly to prevent further deterioration. If any repairs are needed, it is recommended to consult a professional or follow the manufacturer's instructions for proper repair techniques. It is also advisable to protect fiberglass fabric from excessive exposure to sunlight, as prolonged exposure to UV rays can cause fading or discoloration. Using UV-resistant coatings or treatments can help mitigate this issue and prolong the fabric's lifespan. Lastly, storing fiberglass fabric properly when not in use is crucial for maintaining its quality. Ensure that it is kept in a clean and dry environment, away from moisture or extreme temperatures. Rolling or folding the fabric neatly and avoiding any sharp objects or heavy items on top of it will help prevent creasing or damage during storage. By following these maintenance requirements, fiberglass fabric can retain its durability, appearance, and functionality for an extended period of time, making it a reliable choice for various applications.

- Q:How is fiberglass fabric used in the electrical industry?

- Fiberglass fabric is widely used in the electrical industry for various applications due to its exceptional electrical insulation properties. One of the primary uses of fiberglass fabric in this industry is for the insulation of electrical wires and cables. The fabric is often impregnated with a resin or varnish to enhance its insulation capabilities and protect the wires from external elements. Moreover, fiberglass fabric is also employed in the manufacturing of electrical insulation boards and panels. These boards are used to insulate electrical equipment and components such as transformers, circuit breakers, and switchgear. The fabric is typically layered with epoxy or other insulating materials to create a robust and durable insulation system. Another important application of fiberglass fabric in the electrical industry is in the production of electrical insulation tapes. These tapes are used for wrapping and securing electrical connections, providing an additional layer of insulation and protection. Fiberglass fabric tapes are highly resistant to heat and can withstand high temperatures, making them suitable for use in electrical applications. Additionally, fiberglass fabric is utilized in the construction of electrical insulation blankets and covers. These blankets are used to cover electrical equipment such as motors, generators, and transformers to provide an extra layer of insulation and protect against moisture, dust, and other contaminants. Overall, fiberglass fabric plays a crucial role in the electrical industry by providing reliable and effective electrical insulation solutions. Its high dielectric strength, resistance to heat, and durability make it an ideal choice for various electrical applications, ensuring the safe and efficient functioning of electrical systems.

- Q:Directions for use of polyester fiberglass fabrics

- In accordance with the following method of construction, paving polyester glass fiber cloth is very convenient.It will be in the polyester fiber cloth on the road pavement cleaning: remove the dirt, dust and gravel, ensure the asphalt bonding effect.The road has larger cracks when the foundation pit (above 6mm), or damaged, repair should be filled.The adhesive used must be heat reservoir asphalt, emulsified asphalt can not be used, otherwise the bonding effect of polyester fiber decreased.The optimal temperature is 163-204 DEG C - bonded asphalt.The bond must be before the asphalt asphalt spreading without loss of liquidity paving polyester fiber cloth, cloth or body to soak the asphalt, reduce the waterproof performance of fiberglass polyester paving mat.

- Q:Can fiberglass fabrics be used for reinforcement in concrete structures?

- Fiberglass fabrics, woven or knitted fibers of glass, have the capability to reinforce concrete structures. With their high strength and durability, they enhance the tensile strength and crack resistance of the concrete when incorporated. In certain applications, they serve as an alternative to traditional steel reinforcement. Their lightweight nature, non-corrosiveness, and ease of handling make them a suitable option for various concrete structures like walls, slabs, beams, and columns. Moreover, fiberglass fabrics provide additional benefits such as thermal and electrical insulation, as well as resistance to chemicals. However, it is crucial to select and design reinforcement materials based on specific project requirements and engineering considerations.

- Q:How do fiberglass fabrics perform in terms of breathability?

- Fiberglass fabrics are not known for their breathability. Due to their inherent properties and manufacturing process, fiberglass fabrics tend to have a relatively low level of breathability. The tightly woven nature of fiberglass material restricts the passage of air and moisture through the fabric, resulting in decreased breathability. This lack of breathability can cause discomfort and excessive perspiration when wearing fiberglass fabric in warm or humid environments. However, it is important to note that fiberglass fabrics are primarily used for their durability, strength, and heat resistance, rather than their breathability.

- Q:What are the different fiberglass fabric weaves for chemical resistance?

- Chemical resistance can be achieved through various fiberglass fabric weaves. Examples of commonly used weaves include plain, twill, satin, and leno. The plain weave is the most basic pattern, with fibers crisscrossing over and under each other in a simple over-under arrangement. This weave provides good strength and chemical resistance, making it suitable for a wide range of applications. Twill weave, on the other hand, is a more intricate pattern where fibers interlace diagonally. This creates a sturdy fabric with improved drapability and tear resistance. Industries requiring chemical resistance, like chemical processing plants, often utilize twill weave fiberglass fabric. The satin weave is a compact pattern that results in a smooth and glossy surface. This weave offers excellent flexibility and chemical resistance, making it ideal for applications where the fabric needs to conform to complex shapes or undergo repeated flexing, such as the production of chemical-resistant gloves. Leno weave is a unique pattern where warp yarns twist around weft yarns, forming a mesh-like structure. This weave provides outstanding stability and prevents unraveling, making it suitable for applications where chemical resistance and durability are vital, like the manufacture of chemical-resistant aprons or curtains. Since each fiberglass fabric weave offers different levels of chemical resistance and other properties, it is crucial to select the appropriate weave based on the specific requirements of the application. Consulting with a fabric specialist or manufacturer is always recommended to determine the most suitable fiberglass fabric weave for chemical resistance in a particular application.

- Q:How is fiberglass fabric used in the filtration industry?

- Fiberglass fabric is widely used in the filtration industry due to its excellent properties and versatility. It is commonly employed in various filtration applications such as air filters, liquid filters, dust collectors, and industrial filtration systems. One of the key advantages of fiberglass fabric in filtration is its high strength and durability. The fabric is made by weaving fine strands of glass fibers together, creating a strong and resilient material that can withstand harsh filtration conditions. This makes it suitable for both high-pressure and high-temperature filtration processes. Furthermore, fiberglass fabric has excellent chemical resistance, making it ideal for filtering corrosive substances or liquids. It is resistant to a wide range of chemicals, solvents, and acids, ensuring that the filtration material does not degrade or react with the filtrate. Another crucial attribute of fiberglass fabric is its high porosity and filtration efficiency. The fabric can be engineered to have specific pore sizes, allowing for the effective removal of different particle sizes and contaminants. It provides a reliable barrier, preventing the passage of undesired particles while allowing the desired filtrate to pass through. Additionally, fiberglass fabric is known for its low resistance to airflow, making it an excellent choice for air filtration applications. It enables efficient air circulation by allowing the passage of clean air while capturing and retaining airborne particles such as dust, pollen, and allergens. Moreover, fiberglass fabric is easy to maintain and clean, increasing its lifespan and efficiency. It can be easily cleaned through various methods such as backwashing, reverse air cleaning, or chemical cleaning, ensuring that it remains effective over time. In summary, fiberglass fabric is a valuable component in the filtration industry due to its strength, durability, chemical resistance, porosity, and filtration efficiency. Its use in air filters, liquid filters, dust collectors, and industrial filtration systems helps to maintain clean and pure environments by effectively removing particles and contaminants.

- Q:Where can fiberglass fabric be purchased?

- There are numerous options for purchasing fiberglass fabric. Specialized stores catering to construction and crafting needs are a common source for finding it. These stores boast an extensive inventory of fiberglass products, encompassing various fabrics in different sizes and types. Moreover, fiberglass material-specific online retailers and websites serve as fantastic alternatives for acquiring and procuring fiberglass fabric. These platforms provide customers with a greater variety and competitive pricing, enabling them to compare and select the most suitable option. Factors to be taken into account while deciding upon the source to purchase fiberglass fabric include quality, price, and shipping alternatives.

- Q:Can fiberglass fabric be used for tent or awning materials?

- Tent or awning materials can indeed utilize fiberglass fabric. Renowned for its robustness, longevity, and ability to withstand adverse weather conditions such as wind, rain, and UV rays, fiberglass fabric is a lightweight yet resilient option for outdoor applications like tents and awnings. Its exceptional tensile strength guarantees resistance to tension and stretching, preventing any tearing or breakage. Moreover, fiberglass fabric often undergoes treatment with coatings or finishes that offer additional safeguarding against water, mildew, and fire. Consequently, it becomes a dependable and versatile material, capable of enduring diverse weather conditions and ensuring the longevity of tents and awnings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Thermal Insulation High Temperature Carbon Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords