Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Silicone coated fiberglass fabric is made by special formulated liquid or wet silicone rubber dispersed or calendered into the high quality fiberglass cloth and vulcanized, dried. This finished silicone fabric inherits the fiberglass insulation fabric's properties and also improve its fireproof, hand fabrication, oil and waterproof, abrasion resistance.

Features: Fireproof, Thermal Insulation, Abrasion Resistance, Waterproof

Application: Thermal Insulation Cover, Blanket, Jacket, Cover, Pad, Fabric Expansion Joint, Flexible Connector, Welding Blanket, Fire Blanket, Fireproof Curtain, Smoke Curtain

PRICE: USD3.5 per square meter

UNIT: square meter

MOQ: 500 square meter

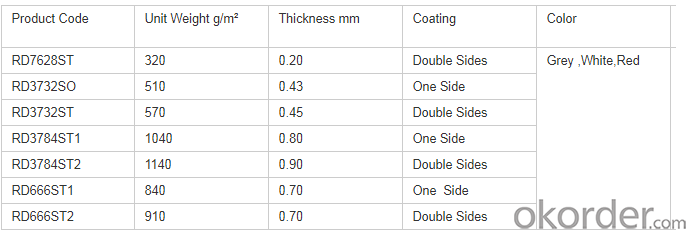

Weight: 140gsm-3000gsm

Width: 90mm to 2000mm or customized

Yarn Type: E-glass

Standing temperature -50℃-550℃

Product name: Silicone Coated Fiberglass Fabric

Coating/Finish/Surface Treatment: Silicone coated

Roll length: 50 meter or customized

Color: Grey, Red, Black, White, Salmon, Green, Blue, Yellow, or customized

Weave Type: Twill, Satin, plain woven or customized

Alkali content: alkali free

Processing service: cutting

Material: fiberglass

Thickness: 0.1mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Can fiberglass fabrics be used for insulation in refrigeration systems?

- Yes, fiberglass fabrics can be used for insulation in refrigeration systems. Fiberglass is a common material used for insulation due to its excellent thermal properties. It is a lightweight and durable material that can effectively resist heat transfer, making it suitable for insulating refrigeration systems. Additionally, fiberglass fabrics can be easily molded or shaped to fit the specific needs of the refrigeration system, ensuring a proper and tight insulation. It is also resistant to moisture, which is important in refrigeration systems where condensation can occur. Overall, fiberglass fabrics are a reliable choice for insulating refrigeration systems and are commonly used in the industry.

- Q: How is fiberglass fabric measured and sold?

- Typically, weight, thickness, and width are the factors used to measure and sell fiberglass fabric. The weight of the fabric is indicated in ounces per square yard (oz/yd²), which signifies the amount of fiberglass material in a given area. A higher weight indicates a denser and stronger fabric. The intended use determines the common weight range, which can vary from 4 oz/yd² to 20 oz/yd². Another important measurement is the fabric's thickness, also known as its thickness. It is usually expressed in mils (1 mil = 0.001 inch) or millimeters (mm). The thickness of fiberglass fabric can vary depending on its application. Thinner fabrics offer more flexibility and are easier to mold, while thicker fabrics provide greater strength and durability. When measuring and selling fiberglass fabric, the width of the fabric roll is also a consideration. It is typically measured in inches or centimeters and refers to the width of the fabric roll. Common widths for fiberglass fabric range from 38 inches (96.5 cm) to 60 inches (152.4 cm). The width is an important factor to determine the quantity of fabric required for a specific project. Fiberglass fabric is commonly sold in rolls or by the yard. The length of the rolls may vary depending on the manufacturer, but common lengths are 50 yards (45.7 meters) or 100 yards (91.4 meters). Additionally, retailers may offer fiberglass fabric by the yard, allowing customers to purchase the desired length for their specific needs. In conclusion, fiberglass fabric is sold based on weight, thickness, width, and length. By considering these factors, customers can select the most suitable fiberglass fabric for their intended applications.

- Q: What are the different weights available for fiberglass fabric?

- Fiberglass fabric is available in various weights, typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight of fiberglass fabric refers to the density or thickness of the fabric, which can vary depending on the intended application and desired strength. Some common weight options for fiberglass fabric include: - 3 oz/yd² (102 g/m²): This is a lightweight option suitable for applications where flexibility and ease of use are important, such as in lightweight composite parts, surfboards, or small craft repairs. - 5 oz/yd² (170 g/m²): This is a medium weight fabric that offers a balance between flexibility and strength. It is often used in boat building, automotive parts, and general fiberglass repairs. - 8 oz/yd² (272 g/m²): This is a heavier weight fabric that provides increased strength and durability. It is commonly used in applications that require higher impact resistance, such as in the construction of industrial tanks, pipes, or structural reinforcements. - 10 oz/yd² (340 g/m²) and above: These are heavyweight options that offer maximum strength and rigidity. They are typically utilized in demanding applications such as aerospace, wind energy, or heavy-duty industrial equipment. It is important to consider the specific requirements of your project when choosing the weight of fiberglass fabric. Factors such as the level of strength needed, flexibility desired, and the type of resin or adhesive being used should be taken into account to ensure the fabric meets the necessary specifications.

- Q: How is fiberglass fabric cleaned?

- Fiberglass fabric can be cleaned easily with some simple steps. Firstly, remove any loose dirt or debris by vacuuming or gently brushing the fabric. For general cleaning, prepare a solution of mild detergent and warm water. Gently scrub the fabric using a soft brush or sponge, making sure to cover all areas evenly. Avoid using harsh chemicals or abrasive materials, as they may damage the fabric. After scrubbing, rinse the fabric thoroughly with clean water to remove any soap residue. Finally, allow the fabric to air dry completely before using it again. Following these steps will help maintain the cleanliness and durability of your fiberglass fabric.

- Q: How is fiberglass fabric used in the production of protective clothing?

- Fiberglass fabric is commonly used in the production of protective clothing due to its unique properties that provide excellent protection against various hazards. The fabric is made by weaving fine strands of glass together, resulting in a strong and durable material. One of the primary uses of fiberglass fabric in protective clothing is for its fire-resistant properties. The fabric has a high melting point, making it ideal for protecting workers from flames, sparks, and extreme heat. It acts as a barrier, preventing the clothing from catching fire and reducing the risk of burns. Additionally, fiberglass fabric is resistant to chemicals and corrosive substances. This makes it suitable for protective clothing in industries where workers may be exposed to hazardous chemicals or acids. The fabric serves as a protective layer, preventing these substances from penetrating through to the skin and causing harm. Furthermore, fiberglass fabric is highly resistant to abrasion and tearing. This makes it an excellent choice for protective clothing in industries where workers may encounter rough or sharp materials. The fabric helps to prevent injuries by acting as a barrier against cuts, scrapes, and punctures. Moreover, fiberglass fabric is lightweight and breathable, allowing for comfortable wear over extended periods. It does not trap heat or moisture against the body, reducing the risk of heat stress or discomfort. This is especially important for workers who need to wear protective clothing for long hours. In conclusion, fiberglass fabric is used in the production of protective clothing due to its fire-resistant, chemical-resistant, and abrasion-resistant properties. It provides a reliable barrier against various hazards, ensuring the safety and well-being of workers in industries where protective clothing is necessary.

- Q: Can fiberglass fabrics be used for insulation in industrial boilers?

- Indeed, insulation in industrial boilers can be accomplished by employing fiberglass fabrics. Fiberglass, renowned for its exceptional thermal resistance characteristics, is widely favored for insulation purposes across numerous domains. This lightweight and pliable material adeptly captures heat and thwarts its dispersion to the adjoining surroundings. In industrial boilers, fiberglass fabrics can be employed as insulating covers or jackets, thereby preserving heat within the system and heightening energy efficiency while minimizing heat dissipation. Furthermore, fiberglass boasts a non-combustible nature, rendering it a secure choice for insulation in high-temperature settings like industrial boilers.

- Q: Can fiberglass fabric be used for insulation in cryogenic systems?

- Fiberglass fabric, known for its outstanding thermal properties and low thermal conductivity, finds application in insulation for cryogenic systems. Its ability to minimize heat transfer and sustain low temperatures makes it an effective option. Furthermore, it exhibits resilience against extreme temperatures and remains impervious to degradation or loss of insulation properties under cryogenic conditions. Consequently, fiberglass fabric emerges as a suitable candidate to insulate cryogenic systems, guaranteeing their efficient and safe operation.

- Q: What is the cost range for fiberglass fabrics?

- The price range of fiberglass fabrics can differ based on a variety of factors, including the fabric's quality, weight, and width, as well as the supplier and any additional features or treatments applied to it. On average, fiberglass fabrics typically cost between $5 and $20 per yard. However, certain high-end or specialized fiberglass fabrics that possess specific properties or finishes can have higher price tags, sometimes exceeding $50 per yard or even more. It is important to remember that these prices are only approximate and may vary due to market conditions and individual suppliers. Furthermore, bulk orders or wholesale purchases might offer discounts, so it is advisable to directly contact suppliers for accurate pricing information.

- Q: How is fiberglass fabric used in the medical industry?

- Fiberglass fabric is used in the medical industry for various applications. It is commonly used in the manufacturing of casts and splints, providing rigid support and immobilization to injured bones or joints. The fabric is lightweight, breathable, and offers excellent strength, making it an ideal choice for this purpose. Additionally, fiberglass fabric is used in the production of medical tapes and dressings, providing a durable and reliable material that can adhere securely to the skin.

- Q: How do fiberglass fabrics perform in terms of UV resistance?

- Fiberglass fabrics generally have excellent UV resistance due to the inherent properties of the material. The fibers used in fiberglass fabrics are typically made of glass, which is naturally resistant to UV rays. This resistance allows fiberglass fabrics to withstand prolonged exposure to sunlight without significant degradation or weakening. As a result, these fabrics are often used in outdoor applications where UV protection is crucial, such as in awnings, sunshades, or boat covers.

Send your message to us

Fiberglass Fabrics with Thermal Insulation Silicone Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords