Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

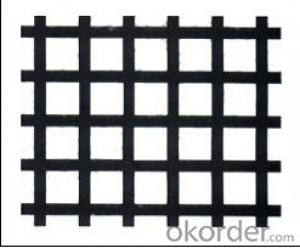

Warp Knitting Polyester geogrid

The Warp Knitting Polyester geogrid selects the excel in synthetic fiber as a raw material,uses the warp knitting oriented structure,latitude and longitude in the fabric to the yarn between not curving condition,the intersection unifies mutually with the excel in textile fiber filament bundle,forms the reliable combining site,displays its mechanical properties fully.

Product Function

2.Characteristics

1. Each kind of higher Uygur path,railroad’s soft roadbed enhancement isolation different base earth material.

2. The river bank,the slope of embankment strengthen stably.

3. Each kind of ground strengthens stably.

4. Strengthens the bridge connection surface.

3.Application

1. Geogrid width ranging from 1000mm to 6000mm

2. High intensity, high module, low slow change ,anti-aging , anti-embrittlement, tensile strength to be high strength.

3. High anti-peel strength ,with the soil crushed stone binding force strong and may pre-design many kinds of characteristics.

4.FAQ

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | ±5 |

Note: The Warp Knitting Polyestergeogrid are available with a width range of 1000mm~6000mm.Other specifications are also available on customer request.

- Q: Can fiberglass fabrics be used for reinforcement in plastic products?

- Indeed, fiberglass fabrics have the ability to be used as reinforcement in plastic products. Renowned for their exceptional strength and durability, fiberglass fabrics prove to be an optimal selection when it comes to fortifying plastic materials. Typically, the fiberglass fabric is saturated with a resin, which, upon solidification, forms a robust and inflexible composite structure. This reinforcement aids in enhancing the mechanical properties of the plastic product, such as augmenting its tensile strength, rigidity, and ability to withstand impacts. Moreover, fiberglass fabrics provide outstanding dimensional stability and resistance to chemicals, rendering them suitable for a wide variety of plastic applications. All in all, fiberglass fabrics are highly favored for their unparalleled strength and performance characteristics in the realm of reinforcing plastic products.

- Q: Can fiberglass fabric be used for making sports helmets?

- Sports helmets can indeed be made using fiberglass fabric. This type of fabric is renowned for its robustness, long-lasting nature, and ability to withstand impacts, making it an optimal choice for creating sports equipment like helmets. Molded into the desired shape and thickness, fiberglass fabric provides exceptional defense against potential impacts during sports activities. Moreover, its lightweight property is crucial in guaranteeing comfort and reducing strain on the wearer. Combining fiberglass fabric with foam padding or other materials further enhances the safety features of the helmet. In conclusion, fiberglass fabric proves to be a dependable option for producing sports helmets that focus on safety and performance.

- Q: Can fiberglass fabric be used for reinforcement in pipes and tanks?

- Indeed, pipes and tanks can benefit from the reinforcement offered by fiberglass fabric. This material boasts exceptional strength and durability, along with its ability to resist corrosion, rendering it an optimal selection for reinforcing structures that might endure severe chemicals or extreme temperatures. The fabric can be affixed to either the inner or outer surface of the pipe or tank, delivering enhanced stability and strength. Furthermore, fiberglass fabric offers the advantage of being lightweight and flexible, enabling it to conform effortlessly to the shape of the pipes or tanks, guaranteeing a reliable and efficient reinforcement.

- Q: Can fiberglass fabric be used for curtains and drapes?

- Yes, fiberglass fabric can be used for curtains and drapes. Fiberglass fabric is a versatile material that offers several benefits for curtains and drapes. Firstly, fiberglass fabric is known for its durability and strength, making it a long-lasting choice for curtains and drapes. It can withstand regular use and is resistant to wear and tear, ensuring that your curtains and drapes will remain in good condition for a long time. Additionally, fiberglass fabric is often treated with a special coating that makes it flame-resistant. This is a crucial feature for curtains and drapes, especially in areas where fire safety is a concern. The flame-resistant properties of fiberglass fabric provide an added layer of protection and peace of mind. Moreover, fiberglass fabric is also known for its insulation properties. It can help to regulate temperature and block out unwanted drafts, making it an excellent choice for curtains and drapes in both cold and hot climates. The insulation properties of fiberglass fabric can contribute to energy efficiency in your home, helping to reduce heating and cooling costs. Furthermore, fiberglass fabric is lightweight and easy to maintain. It is typically stain-resistant, making it easier to clean and maintain the appearance of your curtains and drapes. Fiberglass fabric also tends to resist fading from sunlight exposure, ensuring that your curtains and drapes will maintain their color and vibrancy over time. In summary, fiberglass fabric can definitely be used for curtains and drapes. Its durability, flame-resistant properties, insulation capabilities, and ease of maintenance make it a practical and versatile choice for window treatments.

- Q: What are the different applications of fiberglass fabric in the oil and gas industry?

- Due to its unique properties and benefits, fiberglass fabric has found several applications in the oil and gas industry. In this industry, fiberglass fabric serves various purposes: 1. Insulation: Fiberglass fabric is commonly used to insulate pipes, tanks, and equipment in order to prevent heat loss or gain. It helps maintain consistent temperatures, reducing energy consumption and ensuring efficient operations. 2. Fire protection: With excellent fire-resistant properties, fiberglass fabric is ideal for creating fire barriers, fireproof curtains, and fire blankets in the oil and gas industry. It effectively contains and controls flames during emergencies. 3. Corrosion resistance: Fiberglass fabric's corrosion resistance makes it suitable for protecting pipes, tanks, and vessels from degradation caused by harsh chemicals or environmental conditions. It is used to fabricate corrosion-resistant linings. 4. Reinforcement: Fiberglass fabric enhances the structural integrity and durability of pipes, tanks, and equipment as reinforcement material. Its high tensile strength and low weight make it a preferred choice. 5. Filtration: Fiberglass fabric is utilized for manufacturing filter bags and filter media that effectively capture solid particles, contaminants, and impurities from gases and liquids. These filters ensure smooth operations and prevent equipment damage. 6. Abrasion resistance: In applications where equipment is exposed to abrasive materials or environments, fiberglass fabric acts as a protective layer, preventing wear and tear and extending equipment lifespan. 7. Electrical insulation: Due to its non-conductive properties, fiberglass fabric is suitable for various electrical applications in the oil and gas industry. It ensures safety and prevents electrical hazards by insulating cables, wires, and electrical equipment. Overall, fiberglass fabric offers numerous advantages in terms of insulation, fire protection, corrosion resistance, reinforcement, filtration, abrasion resistance, and electrical insulation in the oil and gas industry. Its versatility and ability to withstand harsh environments make it a preferred material for critical applications in this sector.

- Q: Are fiberglass fabrics suitable for use in the marine industry?

- Yes, fiberglass fabrics are suitable for use in the marine industry. They are highly durable, lightweight, and resistant to moisture, making them ideal for applications such as boat hulls, decks, and interiors. Additionally, fiberglass fabrics offer excellent strength-to-weight ratio, resistance to corrosion, and can be easily molded into various shapes, making them a popular choice in the marine industry.

- Q: Can fiberglass fabrics be used for insulation in industrial machinery?

- Yes, fiberglass fabrics can be used for insulation in industrial machinery.

- Q: How does fiberglass fabric perform in insulation against heat transfer?

- The exceptional performance of fiberglass fabric in heat transfer insulation can be attributed to its unique physical properties and composition. It is produced by weaving together fine strands of glass fibers to create a textile material. These glass fibers possess a high resistance to heat, effectively slowing down the conduction and convection of heat. The insulation properties of the fabric are further enhanced by its ability to trap air within its fibers. Due to its poor heat conducting abilities, air acts as an additional barrier against heat transfer when it is trapped in the fabric's air pockets. This property is commonly referred to as the fabric's thermal insulation or R-value. Furthermore, fiberglass fabric exhibits low thermal conductivity, meaning it does not easily absorb or transmit heat. This characteristic prevents heat transfer through the fabric, making it an ideal choice for insulation purposes. Additionally, fiberglass fabric is capable of withstanding high temperatures, making it suitable for applications that require heat insulation. It can endure temperatures of up to 1000 degrees Fahrenheit without experiencing degradation or loss of its insulating properties. In conclusion, the combination of fiberglass fabric's thermal resistance, low thermal conductivity, and air-trapping abilities make it highly effective in insulating against heat transfer. It finds extensive use in industries such as construction, automotive, aerospace, and manufacturing, where energy efficiency and safety require reliable thermal insulation.

- Q: When decorating, how can the waterproof of kitchen and toilet be checked and accepted?

- When did the waterproof rinse again. The wall height shall not be less than 30 cm. The general construction waterproof when 30 cm rinse. His in the renovation process will be at least 1 meters waterproof... After drainage. Rinse test. A minimum of not less than 24 hours. Down to check whether the water seepage. Then rinse again

- Q: How is fiberglass fabric used in the production of automotive body parts?

- Fiberglass fabric is commonly used in the production of automotive body parts due to its lightweight, high strength, and corrosion-resistant properties. It is often used as a reinforcement material in the manufacturing process. The fabric is typically layered with resin and molded into various shapes to create strong and durable body panels, such as hoods, fenders, and bumpers. Additionally, fiberglass fabric can be easily molded, allowing for greater design flexibility and customization options in the production of automotive body parts.

Send your message to us

Self-Adhesive Fiberglass Mesh Fabric - High Quality Warp Knitting Polyester Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords