Fiberglass Mesh Drywall Joint Tape - High Quality Warp Knitted Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

[APPLICATION]

(1)Road surface reinforcement of road, railway and airport road;

(2)Maintenance, reconstruction and widening of old road surface(asphaltum road or cement concrete road

(3)Reinforcement of soft soil roadbed, irrigation channels and water dams.

[PROPERTIES]

(1)High tensile strength in both the warp and weft directions;

(2)Low elongation;

(3)Excellent temperature range;

(4)Good anti-age and alkali-resistance;

(5)Reduce construction cost, extend service life of road and prevent deflection cracks.

1. Tensile strength: From 25kn/m to 200kn/m

2. Break elongation: ≤4%

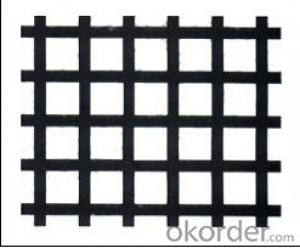

3. Mesh Size: 12.7x12.7mm, 25.4x25.4mm or others

4. Width: 1-6m

5. Length: 50m or 100m or others

6. Coated by modified asphalt

- Q: I'd like to have a glass fiber mesh cloth factory, but have difficulty sources of raw materials and technology, who can give some suggestions and opinions.

- If it is medium and high-grade, you must strictly control the main raw materials: warp and weft. General is the use of big company bushings drawn glass fiber yarn;

- Q: Does anyone know the specification of alkali-resistant fiberglass mesh?

- Specifications are as follows: 1, mesh size: 5mm × 5mm, 4mm × 4mm, 3mm × 3mm. 2, weight per square: 80 grams --160 grams . 3, the length of each volume: 50 m, 100 m or 200 m. 4, width per roll : 1 m --2m. 5, color: White (standard) blue green or other colors. 6 Packing: Blister packaging per roll, four rolls or six rolls of a cardboard box, a 40-foot container can hold 80,000 -150,000 square meters. 7 special specifications and special packaging can be made according to customer's reservation.

- Q: What is a barbed wire glass fiber gridding cloth?

- Barbed wire is a kind of protective products and mainly used for orchard, fish, protection. Glass fiber gridding cloth is different from it and generally used for thermal insulation wall.

- Q: How much money do I need to run a small mesh loom factory ?

- A 2-meter-wide standard loom costs about ?12,000 each. 2 or 3 looms would be enough. You also need a drying oven, about ?10,005, a warping machine,about ?3,000, beating crusher costs ?2,000. Then you can start on.

- Q: The difference between alkali resistant mesh cloth, emulsion and urine glue

- For positioning glass fiber mesh cloth glue, we do not know is not the use of adhesive to fix, in fact, glass fiber mesh cloth itself with a certain amount of binder, binder general alkali resistant glass fiber mesh is used in milkLiquid coating stereotypes, and no alkaline, usually use urine gum for coating treatment, stereotypes are almost the same effect,The effect of the coating is only too hard, so it is brittle, and sometimes it breaks easily.

- Q: what's the specification of the external wall thermal insulation mesh?

- The mesh of interior wall is made of glass fiber as the main raw material and the tensile strength resistance is better when used in the exterior wall, and the number of applied grams is not the same, but it is also made through the process of multi-channel, the external wall thermal insulation mesh is generally 80-160 g, quality anti-tensile strength is relatively small, usually about 50-60 grams. the unit weight of interior wall thermal insulation mesh will be generally lighter. The interior wall of this mesh is the ideal material of grc wallboard.

- Q: Which is good, glass fiber composite or carbon fiber?

- Depends on the specific use of requirements, in terms of toughness and energy absorption or better glass fiber, which refers to the use of the same resin base caseIf you use unsaturated resin to make carbon fiber products, it will not be good to see where to go

- Q: How to increase the glass fiber net fabric tensile strength

- The big eye mesh fabric made of component, flue pipe, facing material and backing should be rigid

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- Mainly refers to the glass composition is different,"Base" refers to a certain amount of alkali metal oxide, Na2O, commonly known as C glass fiber, which corresponds to alkali free (E) glass fiber;

- Q: Is glass fiber harmful to people?

- 0.5 O.7 m thick glass fibers can be detected in the lung lavage fluid of patients. In addition, the exposed chest of the bleached soil fiber, green slope stone, sepiolite and other workers showed atypical shadow, and the lung biopsy showed bronchiolitis, reticular fiber hyperplasia and fibrous foci. Skin damage: glass fiber workers have contact dermatitis, but some workers can gradually tolerance, known as "hardening" phenomenon.

Send your message to us

Fiberglass Mesh Drywall Joint Tape - High Quality Warp Knitted Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords