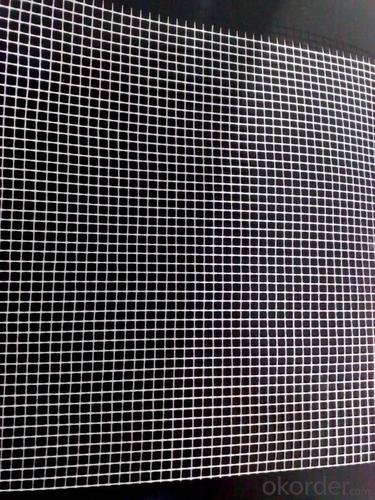

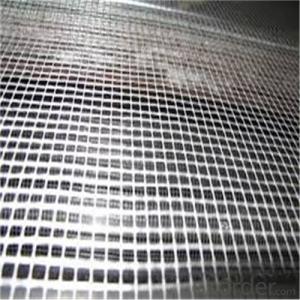

Fiberglass Mesh 45g 2.5*2.5mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x20GP m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fiberglass Mesh 45g 2.5*2.5mm

Coated Alkali-resistant fiberglass mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface.

The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave.

Usage/Applications of Fiberglass Mesh 45g 2.5*2.5mm

1.External Thermo Insulating Composite System (ETICS) & External Insulating Finish System (EIFS)

2.External and internal plaster reinforcement

3.Electrical heating mats

4.Marble Slab Reinforcement / Mosaic Carrier

5.Asphalt reinforcement (roof water-proof)

6.Reinforced lightweight construction boards

Packaging & Delivery

Each roll is wrapped in a shrink film or plastic bag. Then rolls are packed into cartons or pallets.

Production Of Fiberglass Mesh

- Q: Why is the thermal insulation gridding cloth for external walls soft?

- Soft cloth is easy to paste on the walls.

- Q: Which is the best screen for polyester fiber screen window and fiberglass screen window?

- Glass fiber is a kind of inorganic non-metallic material with excellent performance. It has many advantages, such as good insulation, good heat resistance, good corrosion resistance and high mechanical strength, but its disadvantages are brittleness and poor wear resistance.

- Q: Which is better, fiberglass mesh or geogrid?

- The main production of geotextiles, geogrid, geomembrane, bentonite waterproof blanket, I name users, professional manufacturers telephone!!!

- Q: What is the difference between geotextiles and fiberglass fabrics?

- Advantages and characteristics:1., the use of geotextile good permeability and permeability, so that the flow through, so as to effectively retain sand loss.2. geotextile has good water conductivity, it can form a drainage channel within the soil, and the excess liquid and gas discharge in the soil structure.3., geotextile is used to strengthen the tensile strength and deformation resistance of the soil, and to enhance the stability of the building structure, so as to improve the quality of the soil.4., effective stress diffusion, transmission or decomposition, to prevent soil damage by external forces.5. prevent the mixing of sand, soil and concrete between the upper and lower layers.

- Q: How to layout alkali resistant glass fiber grid cloth?

- When seeting walls, gridding cloth can be cut along with the the dividing joint. Reason: the gridding cloth is used for crack resistance and the dividing joint can help reduce wall stress, therefore, it can be a way to reduce crack. Cutting is ok as long as the cardinal plane of base is not affected.

- Q: The advantages of alkali-resistant glass fiber mesh cloth

- Alkali-resistant glass fibers has its notable features compared to alkali-free glass fiber, and medium-alkali glass fiber: it has good alkali-resistant performance, high tensile strength, a strong resistance to corrosion in cement and other alkali medium, and is an irreplaceable reinforcing material in Glass-fiber Reinforced Composite. Alkali-resistant glass fibers are the substrates of glass fiber reinforced cement (GRC) . With the deeping of wall innovation and economic development, GRC has been widely used in building exterior wall panels, insulation board, duct board, garden ornaments and art sculptures, civil engineering and other purposes. They can be made of some products and component that reinforced concrete can't make or impossible to match. They can be used in non-load-bearing, the secondary load-bearing, semi-load-bearing building components, decorative pieces, agricultural facilities and other occasions.

- Q: Does anybody know whether carbon fiber grid is the same as carbon fiber mesh?

- The real electric heating carbon fiber is a kind of carbon fiber and a carbon fiber tow. Once powered on, carbon fiber tow can emit infrared light and heat. And it is heating evenly, suitable to be used under wooden floor. .

- Q: The products of alkali plastic coated glass fiber mesh cloth

- Building sealing tape and so on the glass fiber net fabric varieties:Inner wall insulation glass fiber mesh cloth wall insulation alkali glass fiber net is in the alkali or alkali glass fiber mesh cloth as the substrate and then modified acrylate copolymer coating glue formed. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: what kind of glue does the mesh used on the rubber?

- Cloth is not posted up, processes, it has a unique vulcanization process. Generally it is nitrile rubber. Sometimes it also depends on the requirements of customer, mingled with rubber.

- Q: Should the wall be pasted with gridding cloth before painting?

- If there is obvious crack on the wall, gridding cloth should be pasted on the wall and the crack should be bonded.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2009 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | about 300 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 4000m2 |

| No. of Production Lines | 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | 0.13 usd/m2-0.28usd/m2 |

Send your message to us

Fiberglass Mesh 45g 2.5*2.5mm

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x20GP m²

- Supply Capability:

- 10*40HQ/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords