Biaxial Extruded Geogrids - HDPE Uniaxial Geogrid/Plastic Geogrid Manufacturer with ASTM Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Uniaxial Geogrid Introduction

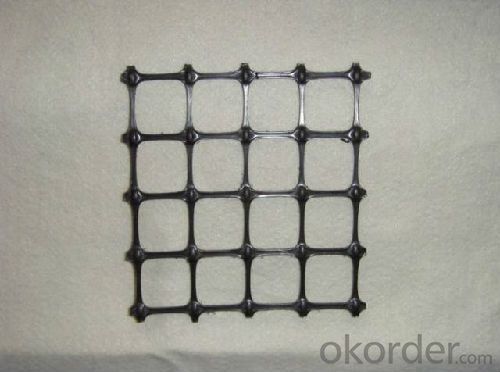

The geogrid is a high strength geosynthetics, is made of high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and then punching network rules, and then the longitudinal tensile and geogrid.

Type: Geogrids

Place of Origin: Shandong, China (Mainland)

Model Number: TGDG35-------220

Material: Plastic,PP,HDPE.

Tensile strength at break: 35kn~220kn

Elongation at break: less than 10%

Roll width: 1.0m, 1.1m, 2.5m, 3.0m

Roll length: 50m, 100m

Package: white pp fabric; black PE membrane

HDPE Uniaxial Geogrid Features

1. In high tensile strength

2. Low elongation

3. Anti-erosion, anti-aging

4. Light weight, structural uniformity, easy for construction

5. Flame retardant, anti-static, good overall performance, easy for mechanized operation

6. Good affinity with base materials

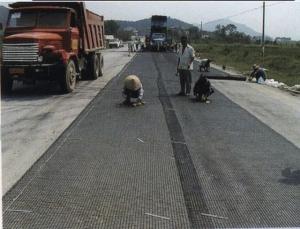

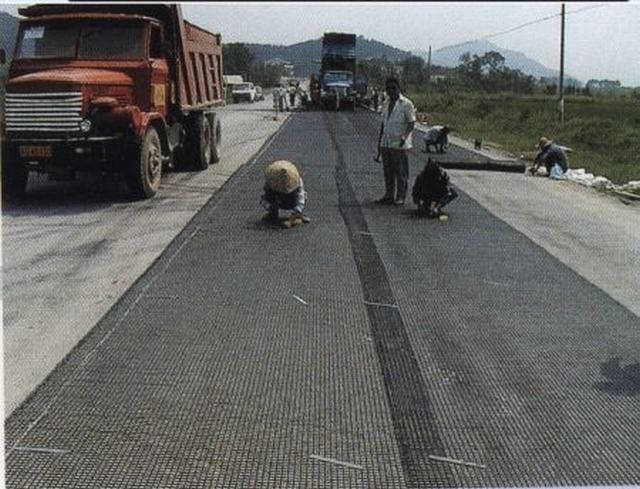

HDPE Uniaxial Geogrid Application

ation

1. Roadbed reinforcement in highway, railway and municipal road

2. Reinforcement and separation in dam and river, improving soft soil bearing capacity and stability

3. Roadbed slope reinforcement, retaining wall reinforcement

HDPE Uniaxial Geogrid Specification

Technical Data

Item | Specification and Index | ||||||

30-30 | 35-35 | 50-50 | 80-80 | 100-100 | 125-125 | 150-150 | |

Limit Tensile Strength (MD&TD)(KN/m) | ≥30 | ≥35 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

Elongation at nominal tensile strength (MD&TD)(%) | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤14 |

Tensile Strength@2% elongation(MD&TD)(KN/m) | ≥10 | ≥12 | ≥17 | ≥28 | ≥35 | ≥43 | ≥52 |

Tensile Strength@5% elongation(MD&TD)(KN/m) | ≥20 | ≥24 | ≥34 | ≥56 | ≥70 | ≥86 | ≥104 |

Production Standard : JT/T480-2002 | |||||||

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway, tunnel, slope and embankment etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

3. What's your payment terms?

T/T, L/C at sight, etc

4. What's your delivery time?

Within 15days after receiving your advance payment or orignal L/C.

- Q: How do geogrids help in reducing soil erosion on slopes?

- Geogrids help in reducing soil erosion on slopes by providing reinforcement and stability to the soil. They are placed within the soil and act as a support system, preventing the movement of soil particles downhill. This reinforcement helps to distribute the loads and stresses evenly, reducing the risk of soil erosion caused by water flow or gravity. Additionally, geogrids increase the shear strength of the soil, making it more resistant to erosion and slope failures.

- Q: Can geogrids be used in riverbank protection projects?

- Yes, geogrids can be used in riverbank protection projects. Geogrids provide reinforcement and stability to the soil, preventing erosion and slippage along the riverbank. They are effective in enhancing the strength of the soil while allowing for proper drainage. Geogrids can be installed easily and are a cost-effective solution for protecting riverbanks against erosion and maintaining their stability.

- Q: What are the physical properties of Geosynthetics

- What are the physical properties of geosynthetics? 1, thickness: the thickness of geosynthetics mm. The variation of thickness has a great influence on the porosity, permeability and filtration properties of the fabric. Commonly used the thickness of all kinds of geosynthetics: geomembrane 0.25 ~ 0.75mm, the thickest of up to 2 ~ 4mm;

- Q: How do geogrids improve the performance of flexible bridge abutments?

- Geogrids improve the performance of flexible bridge abutments by providing reinforcement and stabilization to the soil. These synthetic materials are placed within the backfill soil behind the abutment, increasing its strength and load-bearing capacity. Geogrids also help distribute the load more evenly, reducing stress and potential settlement. This reinforcement prevents excessive movement and settlement of the abutment, ensuring its stability and longevity.

- Q: How do geogrids help in reducing the use of natural resources?

- Geogrids help in reducing the use of natural resources by providing reinforcement and stabilization to soil structures. They allow for the use of less soil and aggregate materials in construction projects, reducing the need for excavation and mining of natural resources. Additionally, geogrids improve the durability and longevity of structures, reducing the need for frequent repairs or replacements, further conserving natural resources.

- Q: What is the difference between Geogrid and geogrid

- The geotextile is used to prevent seepage and the geogrid is used to reinforceThe geotextile is mainly used for seepage control, isolation, geogrid are generally used in reinforcement reinforcement, the two are essentially different, in the use of the process is sometimes used in the same project, for example, high-speed railway project is made of polypropylene production grid and polyvinyl chloride polymer and thermoplastic or die of two-dimensional grid or a certain height of 3D grid screen,

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants.

- Q: What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications can vary depending on factors such as soil type, load requirements, and slope stability. It is important to consult engineering guidelines and specifications for each specific application to determine the appropriate geogrid junction spacing.

- Q: How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement and stabilization to soil or aggregates, allowing for the use of thinner layers of materials. This reduces the overall amount of materials required for construction, leading to cost savings and more sustainable practices.

- Q: Geogrid tgsg50-50 what does it mean

- That is, pull, 45KN, I am a manufacturer, geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

Send your message to us

Biaxial Extruded Geogrids - HDPE Uniaxial Geogrid/Plastic Geogrid Manufacturer with ASTM Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords