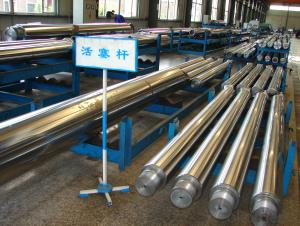

double ended cylinder hydrocylinder hydraulic ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What is the bad effect of the engine oil pressure on the engine when the oil pressure is too high or too low?

- The pressure is too high, the hydraulic tappet internal rigidity is too large, it is easy to cause its door closed tight and so on, the pressure is too low, the hydraulic tappet internal rigidity is too small, will cause the valve clearance is too big. And aggravate wear. Note that this is only a one-sided phenomenon. In fact, when the oil pressure is unstable, the hydraulic tappet itself can compensate for the lack of pressure. I hope the above answer will help you.

- Q: Can the hydraulic cylinder change the nitrogen cylinder?

- Again, the cylinder is generally lighter weight, smaller cylinder, no problem, if you change the cylinder may be greater on the system requirements, in cylinder and large useless.

- Q: Can you tell me if the cylinder can be changed into an oil cylinder (low pressure)?

- Impossible, otherwise, the volume is not the same.

- Q: Hydraulic cylinder application

- Hello, hydraulic cylinder products are widely used in metallurgy, lifting, mining, transportation, ships, forging, machine tools, coal, oil, chemical, scientific research, military, and other industries. It is a hydraulic actuator that converts hydraulic energy into linear motion and mechanical work.The cylinder converts the pressure energy of the compressed air into mechanical energy, and the drive mechanism acts as a linear reciprocating motion, swinging and rotating motion. Mainly used in printing (tension control), semiconductor (spot welder, chip grinding), automatic control, robot and so on.

- Q: Why is the digital hydraulic cylinder not widely used?

- 2, hydraulic system plus flow flow valve; 3, do synchronous cylinder.

- Q: Does the hydraulic cylinder change the inner ring of the cylinder?

- And the seals need to use fluorine rubber, so as not to corrode. But as to the cylinder cylinder with practice is not whimsical, there is such a usage, the pneumatic system has a natural defect, speed instability, especially in low speed, hydraulic pressure is very stable,

- Q: Why do not the industrial furnace door use the hydraulic cylinder and the cylinder?

- Because the oil in the hydraulic cylinder will be heated, it will affect the oil heating, it is difficult to cool the oil heater, this is the reason, in one may be cost savings

- Q: Difference between cylinders of hydraulic cylinders

- The working principle is very simple by using the Pascal principle (F1/A1=F2/A2), the advantages do not need lubricating oil, because his work is medium, and he can realize remote control, can realize stepless speed, no noise etc......

- Q: Hydraulic shock absorbers and hydraulic buffers are the same thing?

- A shock absorber is used between the swing arm rear suspension and the frame to cushion the impact of the bicycle. Traditionally, this is a cylinder in which the piston moves in a reciprocating motion in a straight line. The problem here is that, for such a design, if you want to be lightweight and robust, the cost will be very expensive to adopt the previous solution.

- Q: Apart from the way they are installed, are their sensors universal? That is, can the induction switches used on the A model cylinder be used on the B model cylinders?!Some cylinders use large ones, but others are very small. Are they interchangeable? That is, if the big induction switch is broken, can it be replaced with a small one?

- Are you talking about the magnetic induction switch, only the cylinder with magnetic band can be used?

Send your message to us

double ended cylinder hydrocylinder hydraulic ram

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords