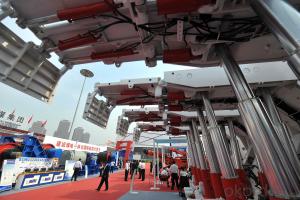

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: For example, I press a workpiece with a hydraulic press, and the pressure gauge shows 0.3MPa. Then I change the cylinder pressure. When I type, I choose the 0.3MPa cylinder instead of the inner diameter of the cylinder.

- To see the pressure gauge is arranged in what position, the general pressure gauge installed in the hydraulic station exit, that is the pressure of the hydraulic system;

- Q: What are the differences and characteristics between punching machine and hydraulic press?

- First, understand the definition of the two:Stamping machine: punching machine, also known as punch, mainly used for sheet metal parts processing.Hydraulic press: hydraulic press is a kind of machine which uses liquid as working medium and uses liquid to transfer pressure to realize various process.There are still many differences between the two, as followsIn principle: the stamping machine drives the flywheel through the motor, and through the clutch, the transmission gear drives the crank connecting rod mechanism, causes the slide block to move up and down, and drives the drawing mold to form the steel plate.

- Q: What is a constant velocity cylinder? What's the difference between a hydraulic cylinder and a hydraulic cylinder?

- The effective effective area on the area of the piston rod cavity. The effective action area of the cylinder speed on both sides of the same, because the two are a piston rod. The most common application of isokinetic cylinder on the machines.

- Q: Kobelco 330 6e excavator hydraulic pump overhaul after the car is going to hold

- 3. low power: the maximum power of the engine shall not be less than 90% of the original design calibration value, and the dynamometer shall be measured according to the relevant provisions.4. fuel consumption rate: the minimum fuel consumption rate of the engine shall not be higher than the original design requirements.

- Q: what to use, there is no suitable cylinder, the company's gas supply is not enough, my device does not have much pressure.The pressure of the air pressure is enough, but the air source is insufficient, and the suitable cylinder can not be selected, so the hydraulic station is used to control the cylinder, but there is no such device, and the friend who knows it tells the thanks!

- At the same speed, under the same thrust conditions, the hydraulic system is much more expensive than the pneumatic system. You can use the hydraulic station to control the cylinder. You might as well buy an air compressor alone.If you have a hydraulic station or a large central hydraulic source, you must use the hydraulic system, you can reduce the work pressure, down to 0.8 MPa, and then send the hydraulic oil to the cylinder, you can also work.

- Q: The difference between gas cylinder and cylinder

- The cylinder control is convenient, the price is low, the energy is easy to obtain, but the force is small, and can not achieve the effect of steady speed

- Q: How to remove the hydraulic cylinder oil seal?

- Is the O ring squeezed out? The front cover should be threaded, carefully to see if there are holes installed, there should be 2 or 4, is not to be painted over, if not, must use the flat shovel.

- Q: always have hydraulic oil leakage, please expert advice, with what seal can avoid, the best zero leakage.

- 200 / min work frequency, high viscosity, slow flow, affect operation sensitivity.It is precisely the year that is too low to cause disclosure. Try to increase viscosity properly.This is a contradiction.

- Q: After running in, the upper cylinder head, the hydraulic jacking rod and the rocker arm are also arranged in the original position, and the cylinder head is not provided with a valve body without gaps

- I. valve clearance: when the valve is completely closed, the gap between the end of the valve stem and the component of the valve train is called the valve clearance. Two, the valve clearance is necessary: when the engine works, the valve will be due to temperature expansion, if the valve and its transmission parts, in the cold when no gap or clearance is too small, in the hot state, and the transmission of the thermal expansion valve will cause the valve is not tightly closed, causing the engine leakage in the power stroke in compression and the power down, don't even start easily when serious. In order to eliminate this phenomenon, the valve clearance is usually used in the cold assembly of the engine to compensate for the expansion after the valve is heated. Some engines use hydraulic tappet, the length of tappet can change automatically, and the thermal expansion of the valve is compensated at any time, so there is no need to reserve the valve clearance. Three, the valve clearance is too large and too small damage, the size of the valve clearance by the engine manufacturer, according to the test to determine. Generally in cold state, the clearance of intake valve is 0.25mm~0.35mm, and the clearance of exhaust valve is 0.30mm~0.35mm. 1, too small: if the valve clearance is too small, the engine in hot state may be due to valve closed lax and leak, leading to power down, or even valve burned.

- Q: Is the hydraulic cylinder at rated pressure the greater the stroke and the greater the pressure, is there a formula?

- The greater the diameter of the cylinder and the larger the area, the greater the pressure it can get.Thrust calculation formula of hydraulic cylinderThrust: 3.14 x 2 x (- / 2 / 1000) of hydraulic pressure

Send your message to us

hydraulic ram for excavator heavy duty machinery

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords