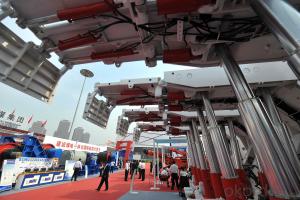

hydraulic ram for excavator heavy duty machinery 2000-2014

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

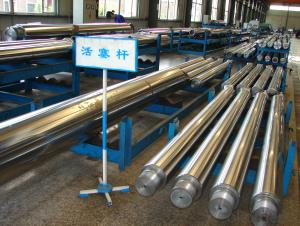

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: Is it possible to change the hydraulic cylinder of the hydraulic lifting platform to the cylinder?

- The pressure cylinder requires tightness, and the hydraulic cylinder is not suitable to be changed into an air pressure cylinder, and the change is equivalent to making a new cylinder.

- Q: What do three hydraulic cylinders need? Is it okay to use PLC? Specific point, I do not understand electricity 10Two cylinder and clamp the workpiece, a feeding cylinder, a hydraulic cylinder to the specified length after the 1 clamping, then another hydraulic cylinder 2 to the workpiece chamfering quickly return hydraulic cylinder 3, cutting, cutting material after rapid return, the hydraulic cylinder 1 and a clamping cylinder and cylinder return return evacuation then, the next clip material feeding cycle. ----...

- Yes, you need a relay, solenoid valve, depending on how you apply, and what action you need.

- Q: What are the acceptance criteria for hydraulic cylinders?

- And the installation of 1: medium series ISO6020/1-81 hydraulic -160bar system of single rod hydraulic cylinder hydraulic system -250bar ISO6022-81 - Mounting dimensions of single rod hydraulic cylinder - Mounting dimensions of ISO6099-82 hydraulic and pneumatic systems and components of a cylinder installation size and installation type symbol ISO6149-80 hydraulic and pneumatic systems and components - Metric oil - Dimensions and design ISO6547-82 hydraulic hydraulic cylinder and piston guide ring combined seal groove - Dimensions and tolerances of ISO6981-82 hydraulic cylinder piston rod end hinge Earrings - Mounting dimensions of ISO6982-82 hydraulic hydraulic cylinder - piston rod end ball hinge Earrings - installation size ISO7181-82 - hydraulic cylinder hydraulic cylinder and piston rod area ratio ISO8131-86 small hydraulic -160bar a series of single rod cylinder tolerance ISO8132-86 hydraulic -160bar medium and 250bar series single rod cylinder accessories installed ISO8135-86 hydraulic medium and 25 -160bar 0bar series of single rod cylinders - Tolerances of ISO8136-86 hydraulic -160bar medium series single rod cylinder oil port size ISO8137-86 -250bar series single cylinder hydraulic medium - size ISO8138-86 hydraulic oil port -160bar series of small single rod cylinder oil outlet size

- Q: Does the car have no cylinder pressure? Is it related to the hydraulic bottom support?

- The pressure of the cylinder is not at all. It doesn't matter to the hydraulic bottom. The valve is broken

- Q: The surface of the hydraulic rod is chromium, and it often causes strain, scratch, electric shock and so on. The routine method is slow to repair and the effect is not satisfactory. Don't want to play with copper, also do not want to use cold, patch method, because of poor adhesion, never long broken. Is there a better way to fix it?

- Compared with welding repair technology, the problems of local high temperature will not occur. Electroplating repair technology is the use of electrolysis principle, the bath metal ions reduced to metal atoms, and deposited on the metal surface, forming a high binding force and a certain thickness of the repair layer.

- Q: Urgent, how, on the mechanical hydraulic buffer for a large amount? What mechanical pneumatic elements are used?

- The question is too general.Look for the same industry, large enterprises, in their website will be classified according to industry applications, check will be more convincing.

- Q: used as the form of a connecting rod or piston in an automobile crankshaft. What is the minimum allowable value for such a hydraulic cylinder?. This way, the supply of oil cylinder in the rear, I ask the output cylinder allowed the maximum number of transfer, such as cooling good, the highest output can be transferred. How many manufacturers are there in the market?.

- Spinning speed, no speed. Why do you have to do this? Why don't you just use a hydraulic motor directly?

- Q: How to remove the hydraulic cylinder oil seal?

- Is the O ring squeezed out? The front cover should be threaded, carefully to see if there are holes installed, there should be 2 or 4, is not to be painted over, if not, must use the flat shovel.

- Q: Application of hydraulic and pneumatic in industry

- This in the "SMC pneumatic service network" - technical article, there is an article devoted to pneumatic applications, you can look under,

- Q: Why do not the industrial furnace door use the hydraulic cylinder and the cylinder?

- Because the oil in the hydraulic cylinder will be heated, it will affect the oil heating, it is difficult to cool the oil heater, this is the reason, in one may be cost savings

Send your message to us

hydraulic ram for excavator heavy duty machinery 2000-2014

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches