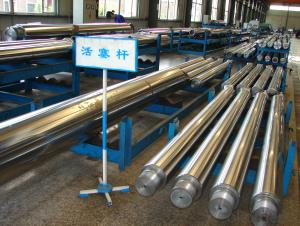

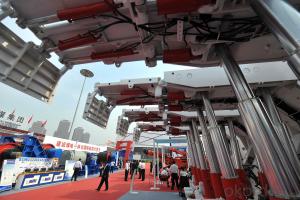

Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What are the differences and characteristics between punching machine and hydraulic press?

- The hydraulic press is that the oil pump transfers the hydraulic oil to the integrated cartridge block, and the hydraulic oil is distributed to the upper cavity or the lower chamber of the oil cylinder through each one-way valve and an overflow valve, and the oil cylinder is moved under the action of the high pressure oil.Use: the machine is suitable for hydraulic load center parts forming, bending, flanging and other processes, with a blanking buffer device, can also be used for punching, blanking and processing, is the product of choice for the shipbuilding industry, pressure vessel industry and chemical industry. Stamping machine is mainly used for sheet metal parts processing.classification

- Q: Kobelco 330 6e excavator hydraulic pump overhaul after the car is going to hold

- The engine has to be overhauled with strict standards. The following are the important "indicators" for the engine to be overhauled. The signs are that the surface engines will be overhauled.1. cylinder pressure difference: cylinder compression pressure should be consistent with the original design requirements for tachometer, cylinder pressure gauge inspection does not meet the requirements for the unqualified cylinder pressure difference per cylinder pressure and cylinder average pressure difference less than 8% with tachometer, cylinder pressure gauge or engine analyzer to measure (does not meet the standards of the Elantra engine the cylinder pressure difference required for unqualified). When the engine cylinder pressure is lower than its Wyatt standard value will have a serious black smoke.2. idle fluctuation: engine idle running stability, the speed meets the original design requirements. The speed fluctuation is not more than 50r/min. The tachometer is used for running test or by engine comprehensive analyzer.

- Q: Master, I want to make a set of hydraulic equipment for hydraulic piston and cylinder head with us how to adjust the tolerances. (H refers to the tolerance zone of the hole, f refers to the tolerance zone of the shaft, right? What does H7F8 mean?) I do not understand these written knowledge, it is best to say that the size of the piston head and cylinder bore how to fit, and can take specific figures for example, the best, the more detailed the better. To install the piston ring high speed heating will do, how to solve it, large caliber and long trip for us.

- 1, GB standard: hole tolerance class with uppercase English letters, shaft tolerance class with lower case English letters, H7/f8 refers to the hole and shaft tolerance zone, but the specific tolerance depends on the size of the section, can be examined.

- Q: What can be used in hydraulic equipment factory

- Most of the factory are used, hydraulic equipment, machinery and equipment power source!

- Q: What is pneumatic oil? Is it the same as hydraulic oil?

- Pneumatic and hydraulic oils are not oils. Pneumatic lubricants require high oxidation resistance and lubricity, while hydraulic oils require good abrasion resistance, oxidation resistance, lubricity and foam resistance as well as anti emulsification effects. Pneumatic lubricants are generally thinner than hydraulic oils.

- Q: What are the characteristics of the cylinder compared with the hydraulic cylinder?

- High speed, quick response (but less response than hydraulic cylinder)Compressed media cheapThere is no pollution problem (or pollution problems are easy to solve - for food processing and other industries which are very sensitive to pollution)

- Q: What is the basic working principle of the cushion device in the hydraulic cylinder?

- Because of the cylinder, cylinder pressure required is large, usually in the front end is provided with a cylinder buffer mechanism, such as buffer piston, as shown in the figure (if not insert picture ah).

- Q: How to distinguish hydraulic cylinders and cylinders?

- The material of the cylinder is that the alloy is very light, and the hydraulic cylinder is very heavy;

- Q: How to remove the hydraulic cylinder oil seal?

- Is the O ring squeezed out? The front cover should be threaded, carefully to see if there are holes installed, there should be 2 or 4, is not to be painted over, if not, must use the flat shovel.

- Q: Apart from the way they are installed, are their sensors universal? That is, can the induction switches used on the A model cylinder be used on the B model cylinders?!Some cylinders use large ones, but others are very small. Are they interchangeable? That is, if the big induction switch is broken, can it be replaced with a small one?

- Are you talking about the magnetic induction switch, only the cylinder with magnetic band can be used?

Send your message to us

Factory Direct Custom Made Double Acting Hydraulic Ram Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches