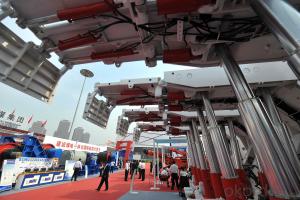

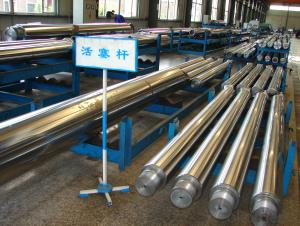

small bore hydraulic ram for boring machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1.ISO9001:2008

2.Seal:Merkel or Parker

3.Working pressure:16-25Mpa.

4.10 years of experienc

5.Material:CK45

CMAX series engineering hydraulic Cylinder

(1)working pressure:16MPa

(2)Piston diameter: 40-250mm

(3)Seals:Merkel or Parker

(4)Sensor: MTS or Balluff

BOOM,ARM,BUCKET CYLINDER | ||||||

| R55 | R60-5-7 | R130 | R200-5 | R210-5 | R220 | R225-7 |

| R260LC-5 | R280 | R290 | R300 | R305-7 | R450-5 | R215-7 |

| R210LC-3 | R335-7 | |||||

cylinder diamete r (mm) | piston rod diameter (mm) | max stroke (mm) | ||

| 40 | 20 | 22 | 25 | 500 |

| 50 | 25 | 28 | 32 | 600 |

| 63 | 32 | 35 | 45 | 800 |

| 80 | 40 | 45 | 55 | 2000 |

| 90 | 45 | 50 | 63 | 2000 |

| 100 | 50 | 55 | 70 | 4000 |

| 110 | 55 | 63 | 80 | 4000 |

| 125 | 63 | 70 | 90 | 4000 |

| 140 | 70 | 80 | 100 | 4000 |

| 150 | 75 | 85 | 105 | 4000 |

| 160 | 80 | 90 | 110 | 4000 |

| 180 | 90 | 100 | 125 | 4000 |

| 200 | 100 | 110 | 140 | 4000 |

| 220 | 110 | 125 | 160 | 4000 |

| 250 | 125 | 140 | 180 | 4000 |

- Q: What is the bad effect of the engine oil pressure on the engine when the oil pressure is too high or too low?

- The pressure is too high, the hydraulic tappet internal rigidity is too large, it is easy to cause its door closed tight and so on, the pressure is too low, the hydraulic tappet internal rigidity is too small, will cause the valve clearance is too big. And aggravate wear. Note that this is only a one-sided phenomenon. In fact, when the oil pressure is unstable, the hydraulic tappet itself can compensate for the lack of pressure. I hope the above answer will help you.

- Q: Which pressure is the cylinder or hydraulic cylinder?

- I used 80 hydraulic cylinders, and now I want to change the cylinder. I don't know how many cylinders I need to buyChasing the answerThis is not clear, sorry

- Q: One hundred1: cylinder 150D-71x-102: cylinder GTD-80/090-P17M3: cylinder XQGA125*160-CA4: hydraulic cylinder COA3110715.035: cylinder MAB125-165P6: hydraulic cylinder SCI80/56 H1765XV980YPSX7: hydraulic cylinder CA100*70*350T8: hydraulic cylinder COA3112458.029: pneumatic gate valve cylinder DN600I need to find each cylinder bore. Stroke. The diameter of the piston rod installation. Pressure rating!!!Urgent need for support for the master! Thank you!!! (the more specific, the more important.)What's the form? Do not understand.. can not point out in detail...

- Where did you get the specifications for each cylinder? Just look for a sample of the brand, and you can see the parameters you need!!! Otherwise, there is no way! Moreover, you can see, you do not write a lot of specifications! So, you still need..... Ha-ha!

- Q: Multi axis drilling hydraulic system design of a horizontal cylinder in the machining production line (conditions: positioning, clamping hydraulic control, machine tool positioning clamping action sequence: - - - - - feeding slide fast forward rewind - stop - release - pull pin fixture, machine work axial cutting force 25000N, acceleration deceleration inertia force 500N 1500N, static friction resistance, friction resistance 850N, fast forward, rewind speed is 100mm/S and the feeding speed of 833mm/min, fast travel 0.1M of 0.04m. Worktable adopts flat guide rail)Tasks and requirements:Determine component specifications and complete hydraulic system loop diagram 1;2. Design the assembly drawing of the hydraulic cylinder 1;3, according to the prescribed format to complete the design, calculation manual 1.

- To the bookstore to buy a "modular machine tool design manual" second volumes, above all.

- Q: How to use hydraulic system to control the feeding of machine tool table and the positioning and clamping device of workpiece

- Two, the role of machine tools:A lathe is a machine tool for turning a rotating workpiece with a lathe tool. Can also be used in the lathe drill, drill reamer taps Banya and knurling tools for the corresponding processing. Lathes are mainly used for machining shafts, disks, sleeves, and other workpieces with revolving surfaces. They are the most widely used machine tools in machine building and repair factories.

- Q: Are hydraulic cylinders, oil cylinders, hydraulic cylinders all the same? What's the difference?

- It's all about one thingI am the repair cylinderThe cylinder is all hydraulic, so it is called a hydraulic cylinder and a hydraulic cylinder, both of which mean one

- Q: What are the characteristics of the cylinder compared with the hydraulic cylinder?

- High speed, quick response (but less response than hydraulic cylinder)Compressed media cheapThere is no pollution problem (or pollution problems are easy to solve - for food processing and other industries which are very sensitive to pollution)

- Q: The main difference between hydraulic circuit and pneumatic circuit

- I. pneumatic basic circuit is the basic component of pneumatic circuit, and complex pneumatic operation system is composed of one or more basic circuits. Compared with hydraulic, pneumatic circuit has its own characteristics:1, an air compressor can simultaneously supply gas to multiple circuits, while hydraulic pumps generally provide only one loop.2. The compressed air will be discharged into the atmosphere directly after the end of the cycle. No hydraulic drive will be necessary to recover the oil into the tank.3, air senior lubrication performance is poor, need additional oil supply device.Two, through the introduction of the previous articles, we generally understand the hydraulic circuit and the use of pneumatic circuit, as well as related presentations, and then we will explore how the cylinder should be chosen.Standard cylinder selection process is generally based on the needs of the job to determine the type of cylinder, installation forms, working pressure, cylinder and stroke, cylinder standard series and product samples for selection, gymnastics as;1, the cylinder output size of the load by 1.15~2 times to select, and accordingly determine the cylinder bore.2, according to the implementation of the agency's travel requirements to determine the cylinder piston stroke length, usually need to leave the margin of 5-20mm.3, according to the speed of the piston movement, select the appropriate inlet diameter, the greater the value, the faster the speed. In order to make the speed steady, a cylinder with a buffer device can be used.

- Q: always have hydraulic oil leakage, please expert advice, with what seal can avoid, the best zero leakage.

- 200 / min work frequency, high viscosity, slow flow, affect operation sensitivity.It is precisely the year that is too low to cause disclosure. Try to increase viscosity properly.This is a contradiction.

- Q: Why do not the industrial furnace door use the hydraulic cylinder and the cylinder?

- Because the oil in the hydraulic cylinder will be heated, it will affect the oil heating, it is difficult to cool the oil heater, this is the reason, in one may be cost savings

Send your message to us

small bore hydraulic ram for boring machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords