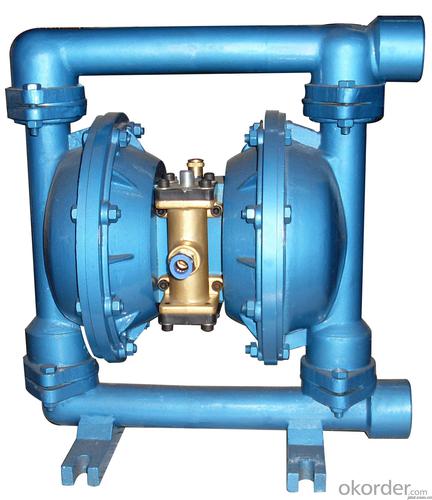

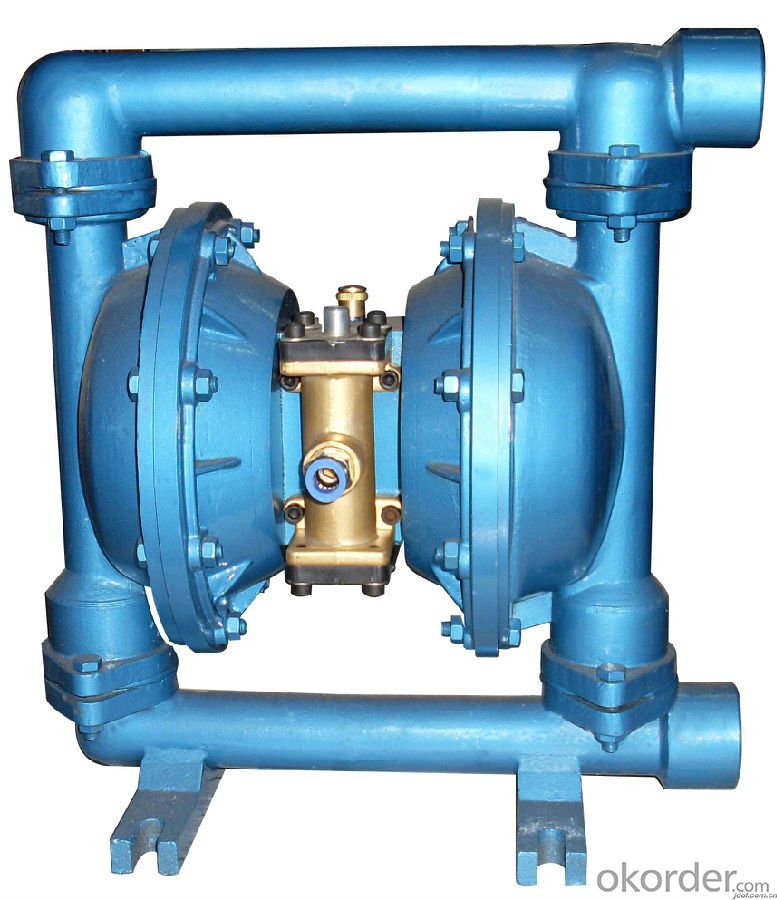

Air Operated Double Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Air operated double diaphragm pump Product description

QBY air operated double diaphragm pumps not only can transfer the flow liquid, but also can transfer some uneasy flowed medium, with the merits of self-priming pump,diving pump, shield pump, slurry pump and impurity pump etc.

1.It’s unnecessary to pour the drawing water, the suction lift reaches 7m height, the delivery lift reaches 70m length and the outlet pressure≥6kgf/cm²;

2.Wide flow and good performance. The diameter allowed to pass the max grain reaches 10mm. The damage is very less to the pump while exchausting the slurry and impurity.

3.The delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment (the pneumatic pressure adjustment is between 1-7kgf/cm²) ;

4.This pump has no rotary parts and no bearing seals. The diaphragm will completely separate the exhausted medium and pump running parts, working medium. The conveyed medium can’t be leaked outside. Thus it will notcause the environment pollution and human body safety danger while exhausting the toxin and flammable or corrsive medium.

5.No lectricity.It’s safe and reliable while using in the flammable and explore places.

6.It can be soaked in medium to work.

7.It’s convenient to use and reliable to work.Only open or close the gas valve body while starting or stopping. Even if no medium operation or pausing suddenly for long time because of accident matters,the pump will not be damaged caused by this. Once over-loading, the pump will auotomatically stop and possesses the selfprotection function. When the load recovers normally, it also can start automatically.

8.Simple structure and less wering parts. This pump is simple in structure, installation and maintance. The medium conveyed by the pump will not touch the matched pneumatic walve and coupling lever etc. Not like other kinds pumps, the performance will drop down.

9.Gradually because of the damages of rotor, gear and vane etc.

10.This pump needn’t the oil lubricant. Even if idling, it has influence to the pump.This is a special characteristic of this pump.

Air operated double diaphragm pump Application

1.The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.

2.The pump can suck the paint,pigment,glue and adhesive etc.

3.The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4.The pump can suck variousgrinding materials, corrosive agent and clean the oil dirt etc.

5.The pump can suck various toxin and flammable or volatility liquid etc.

6.The pump can suck various wedge water,cement sllurry and mortar etc.

7.The pump can suck various strong acid, alkali and corrosive liquid etc.

8.It can be used as a front-step transmission device of the solid and liquid separation equipment.

Air operated double diaphragm pump Technical Data:

Flow rate: up to 30 m³/h

Head: up to 50 m

Speed: max 2900 rpm

Temperature: max 105 °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

- Q: How is three-phase air pump changed into single phase?

- Domestic power in our country is a phase of three-phase electricity as a line of fire, in conjunction with the ground zero line voltage of 220. When the three-phase voltage is 380, the Japanese motor should be three-phase, with 200V single-phase 110V. A transformer is needed to change the power of each phase from 220 to 110 and then to the motor.

- Q: What safety precautions should I take while using an air pump?

- When using an air pump, it is important to follow these safety precautions: 1. Read the instruction manual: Familiarize yourself with the air pump's proper usage, safety guidelines, and any specific precautions provided by the manufacturer. 2. Wear protective gear: Consider wearing safety goggles or glasses to protect your eyes from any potential debris or sparks. 3. Ensure proper ventilation: Use the air pump in a well-ventilated area to avoid inhaling any fumes or gases that may be emitted during operation. 4. Keep flammable objects away: Avoid using the air pump near flammable materials or substances that may ignite easily. 5. Check electrical connections: Inspect the power cord and plug to ensure they are in good condition without any frayed wires or exposed parts. Avoid using the pump if there are any signs of damage. 6. Use a grounded outlet: Always plug the air pump into a properly grounded outlet to minimize the risk of electrical shock. 7. Place it on a stable surface: Ensure that the air pump is placed on a stable and level surface to prevent it from falling or tipping over during operation. 8. Avoid over-pressurization: Do not exceed the recommended pressure limits specified by the air pump's manufacturer. Over-pressurization can cause damage to the pump or result in an explosion. 9. Do not leave unattended: Always supervise the air pump while it is in use and never leave it running unattended. 10. Regular maintenance: Follow the manufacturer's guidelines for regular maintenance, such as cleaning, lubrication, and inspection, to ensure the air pump continues to operate safely and efficiently.

- Q: Can an air pump be used for inflating air cushions for wheelchairs?

- Yes, an air pump can be used for inflating air cushions for wheelchairs.

- Q: Can an air pump be used for inflatable dance costumes?

- Indeed, inflatable dance costumes can indeed make use of an air pump. Typically crafted from lightweight materials, these costumes are intended to be inflated in order to achieve a captivating and distinct appearance. By utilizing an air pump, dancers can effortlessly alter their look for their performance. It is crucial to verify that the air pump is compatible with the costume and possesses the requisite nozzle or attachment, as this will prevent any potential harm to the costume during the inflation procedure.

- Q: Can an air pump be used for inflatable play structures?

- Yes, an air pump can be used for inflatable play structures.

- Q: How to make a simple oxygen pump?

- Oxygen in the water can be increased through the flow of water, not necessarily to the water filling oxygen. Just as the living creatures in the river do not lack oxygen, a reason, because the river is flowing.Understand this principle, oxygen pump is not so complicated. To get a small motor or engine, and power, then the gear in a motor with a plastic or metal sheet made of water,, fan blades and so can, anyway, let the water flow up fast. Just fine. But it's better to buy one than waste so much. Small power pump is only 56 yuan, a little more than ten yuan. At least in terms of electricity, than homemade safety..

- Q: Can an air pump be used for inflatable holiday decorations?

- Yes, an air pump can definitely be used for inflatable holiday decorations. In fact, it is one of the most common and efficient ways to inflate these decorations. An air pump provides a steady stream of air that can quickly and easily fill up inflatable holiday decorations such as Santa Claus figures, Christmas trees, snowmen, and more. It saves you time and effort compared to manually blowing them up by mouth, and ensures that the decorations are properly inflated. Just make sure to use the appropriate nozzle attachment for your specific inflatable decoration, and follow the instructions provided with the air pump and the decoration for optimal usage.

- Q: How does an air pump affect water temperature in fish tanks?

- An air pump does not directly affect the water temperature in fish tanks. Its main function is to provide oxygen to the water by creating water movement and surface agitation. This helps in maintaining a healthy environment for the fish by promoting gas exchange at the water's surface, preventing the water from becoming stagnant, and ensuring adequate oxygen levels for the fish to breathe. However, the air pump can indirectly influence the water temperature in a few ways. First, the air bubbles created by the pump can cause slight evaporation, which can lead to a minor decrease in water temperature. Additionally, the water movement created by the air pump can enhance heat distribution within the tank, preventing hot and cold spots and promoting more even temperature throughout the tank. Moreover, some air pumps are designed to be connected to air stones or diffusers. These devices can be attached to a heater to help distribute heat more evenly throughout the tank. By using an air pump in combination with a heater, the temperature gradient in the tank can be minimized, creating a more stable and suitable temperature range for the fish. In summary, while an air pump does not directly affect the water temperature in fish tanks, it plays a crucial role in maintaining oxygen levels and water circulation, which indirectly contributes to a more stable and suitable temperature environment for the fish.

- Q: How does an electric air pump differ from a manual one?

- An electric air pump differs from a manual one in that it is powered by electricity, allowing it to inflate items more quickly and effortlessly. Unlike a manual pump, an electric pump does not require physical exertion or continuous pumping by hand. It typically comes with different nozzle attachments and settings for various inflation needs, making it more versatile.

- Q: Can an air pump be used for inflating air curtains?

- No, an air pump is not typically used for inflating air curtains. Air curtains are typically inflated using a blower or fan system specifically designed for that purpose.

Send your message to us

Air Operated Double Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords