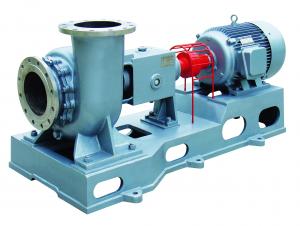

Mixed Gas Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Mixed gas water pump is suit for clear water,handling foamy,vloatile liquids,and mixture of liquid,vapor and air.

This kind of pump owns some advantages such as;compact small shape,light weight,simple structure,low noise,convernient for fixing.The axis seals are sealed by machinery.Thus,its sealed effect is very good.Motor Power 1.5~4KW, flow 4.5~17(m3/h), head3~48m。

- Q: How to prevent freezing of an air pump in cold temperatures?

- To prevent freezing of an air pump in cold temperatures, there are a few measures you can take: 1. Insulate the air pump: Wrap the air pump with insulation material to protect it from the cold air. This can be done using foam or insulating tape, ensuring that all exposed parts are covered. 2. Use a heat source: Place a heat source near the air pump to keep it warm. This can be a heat lamp, a heating pad, or even a small heater. Just make sure to place it at a safe distance to avoid any potential hazards. 3. Keep the pump running: One of the most effective ways to prevent freezing is to keep the air pump running continuously. The constant movement of air can help prevent the buildup of condensation and subsequent freezing. Consider using a timer to ensure the pump doesn't turn off during the night or when not in use. 4. Store the pump indoors: If possible, bring the air pump indoors when temperatures drop significantly. Storing it in a warmer environment will greatly reduce the risk of freezing. 5. Use a de-icer: Consider using a de-icer specifically designed for air pumps. These products can be added to the pump's intake or directly into the water to prevent freezing. Follow the manufacturer's instructions for proper usage. Remember, taking precautions to prevent freezing is crucial as it can damage the pump and reduce its effectiveness. By insulating, providing heat, keeping it running, storing it indoors, or using a de-icer, you can ensure the longevity and functionality of your air pump even in cold temperatures.

- Q: 10Kg air compressor is equivalent to the big air pump

- 10kg=1.0MPa=10 atmospheric pressure10kg refers to the exhaust pressure of the air compressor, and you also need to determine the exhaust of the air compressor

- Q: Are air pumps suitable for inflating air tents?

- Air tents can be effectively inflated using air pumps, making them the recommended method for setting up these tents. The design of air tents allows for quick and easy inflation using an air pump, which applies the necessary pressure to inflate the tent's air beams and create a sturdy structure. By using an air pump, a consistent and even inflation is ensured, enabling efficient and secure tent setup. Moreover, air pumps often include various nozzles and adapters to accommodate different valve types, making them compatible with a wide range of air tents. Overall, air pumps are a dependable and convenient tool preferred by numerous outdoor enthusiasts for inflating air tents.

- Q: For crayfish, does the oxygen pump take 24 hours? Will it burn out?

- I don't need to beat oxygen when I'm a waterfall. Unless new shrimp is introduced into the tank, the shelling is isolated, and cultures of nitrifying bacteria and high temperatures are developed.

- Q: Are air pumps suitable for wastewater aeration?

- Yes, air pumps are suitable for wastewater aeration. Aeration is an essential process in wastewater treatment as it helps to introduce oxygen into the wastewater, promoting the growth of aerobic bacteria that break down organic pollutants. Air pumps, also known as aerators or diffusers, are commonly used to supply the necessary oxygen to the wastewater. These pumps work by forcing air into the water through diffusers, creating bubbles that increase the surface area for oxygen transfer. By supplying oxygen, air pumps support the growth of beneficial microorganisms that aid in the decomposition of organic matter and removal of harmful substances. Furthermore, they help to maintain proper mixing and circulation within the wastewater, preventing the formation of anaerobic zones that can produce foul odors and release toxic gases. Overall, air pumps are an effective and efficient solution for wastewater aeration, contributing to the successful treatment of wastewater and the protection of the environment.

- Q: How energy-efficient are air pumps?

- The energy efficiency of air pumps can vary based on the specific model and usage. Generally speaking, air pumps are quite energy-efficient compared to other appliances. They typically consume a small amount of electricity, especially when compared to larger appliances like air conditioners or refrigerators. To measure an air pump's energy efficiency, its power consumption and air delivery volume are taken into account. High-quality air pumps are designed to deliver a large volume of air while using minimal power. These pumps often incorporate advanced technologies like dual diaphragms or piston systems, which maximize airflow while minimizing energy consumption. Furthermore, certain air pumps offer adjustable settings that allow users to control the rate of airflow. This feature helps optimize energy efficiency by adjusting the pump's output to meet the specific requirements of the aquarium or pond. It's important to note that energy efficiency can also be influenced by factors such as maintenance, proper installation, and the condition of the air pump. Regular cleaning and servicing ensure that the pump operates at its highest efficiency. Additionally, placing the pump in a well-ventilated area and avoiding obstructions prevents overheating and reduces energy consumption. In conclusion, air pumps are generally regarded as energy-efficient due to their low power consumption and ability to deliver a significant volume of air. However, it is advisable to choose a high-quality air pump with adjustable settings and maintain it properly to maximize its energy efficiency.

- Q: How can the oxygen pump in the tank be out of oxygen, or pumping water, but without oxygen?

- You are using a three in one pump! It has two outlets, through a filter, another boost to the water cycle, with a pipe interface at the outlet, the use of negative pressure high speed water flow will generate air suction and blowing in order to achieve the effect of aerobics, there is no bubble flow for the following reasons: 1 the pump placed too deep, 2 outlet dirt, especially is the root of the intake pipe, 3 tracheal blockage.

- Q: Are there air pumps with automatic shut-off features?

- Yes, there are air pumps available in the market with automatic shut-off features. These pumps are designed to automatically stop inflating once a desired pressure level is reached, preventing over-inflation or damage to the item being inflated.

- Q: How does an air pump handle dust and debris?

- The incorporation of filters in its system enables an air pump to effectively handle dust and debris. These filters are strategically placed within the pump to prevent particles from entering its inner workings. The primary filter, typically made of foam or mesh, is responsible for capturing larger particles like dust and dirt. Additionally, there might be secondary filters, such as activated carbon or HEPA filters, which remove smaller particles, allergens, and even odors from the air. When air is drawn into the pump, the first filter captures larger particles, preventing them from causing clogs or damage to the pump's internal components. If secondary filters are present, they further enhance the air quality by trapping microscopic particles, resulting in cleaner and purer expelled air. Regular cleaning or replacement of these filters is necessary to maintain optimal performance. In certain cases, air pumps may also feature a cyclone or centrifugal separator system. This system employs centrifugal force to separate dust and debris from the air, directing them to a separate collection chamber or bag. This mechanism minimizes the amount of dust and debris that reaches the filters, thereby prolonging their lifespan and improving overall efficiency. In conclusion, the design and filtration mechanisms of an air pump ensure the effective handling of dust and debris, facilitating clean and efficient air circulation.

- Q: What is the maximum volume of air an air pump can move?

- The maximum volume of air an air pump can move depends on the specific design and capacity of the pump. It can range from a few liters per minute for small, portable pumps to several cubic meters per minute for larger industrial pumps.

Send your message to us

Mixed Gas Water Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

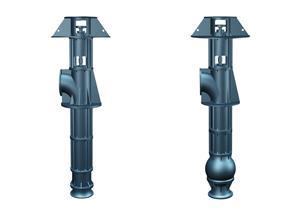

Similar products

Hot products

Hot Searches

Related keywords