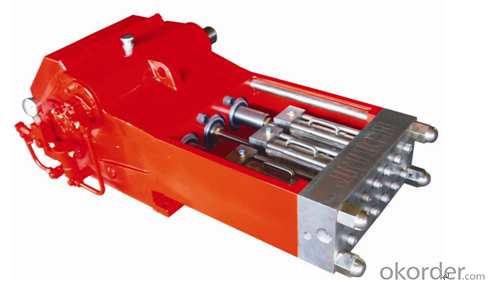

250TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

250TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆Liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants. It can pump fresh water or emulsion liquid similar like fresh water.

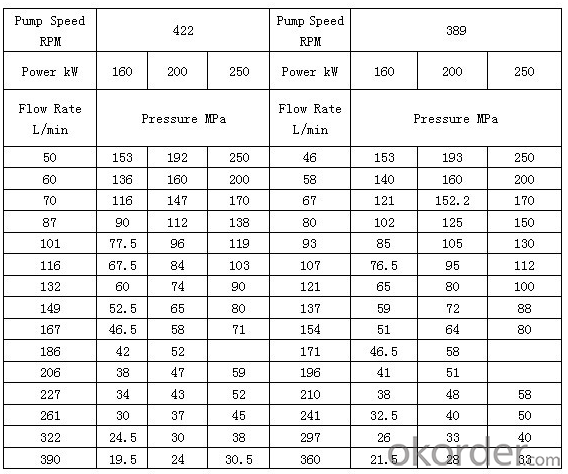

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Can an air pump be used for inflating air mattresses with memory foam tops?

- Certainly! An air pump has the capability to be utilized in the inflation of air mattresses featuring memory foam tops. Air mattresses consisting of memory foam tops generally possess an internal air chamber that can be filled with air by means of a pump. While the memory foam top enhances comfort and support, the inflation procedure remains identical to that of conventional air mattresses. It is imperative to select a pump that is compatible with the valve on the mattress and possesses adequate power to completely inflate it. Certain air pumps even offer dedicated settings designed exclusively for inflating air mattresses, thereby simplifying the process further.

- Q: 10Kg air compressor is equivalent to the big air pump

- The size of the air compressor depends on the amount of gas it produces. The size of the compressor does not determine the size of the compressor!

- Q: Can an air pump be used for inflating air dusters?

- No, an air pump cannot be used for inflating air dusters. Air pumps are typically used for inflating items such as tires, sports balls, or air mattresses. Air dusters, on the other hand, are designed to blow compressed air to clean delicate electronic equipment or hard-to-reach areas. They usually come in aerosol cans and contain a compressed gas, such as difluoroethane or tetrafluoroethane, which is released when the trigger is pressed. Trying to use an air pump to inflate an air duster would not be effective, as it would not provide the necessary pressure or release the compressed gas.

- Q: Are there any specific power requirements for operating an air pump?

- Yes, operating an air pump typically requires a power source such as electricity or batteries. The specific power requirements may vary depending on the type and size of the air pump being used.

- Q: Can an air pump be used for inflatable water parks or play structures?

- Yes, an air pump can be used for inflatable water parks or play structures. In fact, it is highly recommended to use an air pump for inflating these types of structures. An air pump is designed to quickly and efficiently inflate large inflatable objects, such as water parks or play structures, saving both time and effort. Using an air pump ensures that the structures are properly inflated to their recommended pressure, which enhances their stability and safety for users. Additionally, an air pump can also be used to deflate the structures after use, making the process of setting up and packing away much easier. Overall, an air pump is an essential tool for inflating and deflating inflatable water parks or play structures.

- Q: How long does it take to inflate an object using an air pump?

- The time it takes to inflate an object using an air pump depends on the size and type of the object, as well as the power and efficiency of the air pump. It can range from a few seconds for small inflatables to several minutes for larger objects like balloons or tires.

- Q: How does an air pump regulate the pressure being generated?

- An air pump serves the purpose of creating and managing air pressure for various uses. To accomplish this, it utilizes a piston or diaphragm that moves back and forth, generating a pressure disparity. When the piston moves in one direction, it reduces the system's volume, resulting in air compression and pressure increase. Conversely, when the piston moves the other way, it enlarges the system's volume, leading to pressure reduction. To control the generated pressure, air pumps incorporate valves that manage the air flow into and out of the system. These valves open and close at specific pressure thresholds. If the pressure surpasses a set limit, the outlet valve opens, allowing excess air to escape and reducing the pressure. Conversely, if the pressure drops below a predetermined level, the inlet valve opens, permitting air to enter the system and increase the pressure. Through adjusting the opening and closing pressures of these valves, the air pump can precisely regulate the generated pressure to meet the application's specific requirements. This ensures that the pressure remains within the desired range, preventing any potential damage or malfunction caused by excessively high or low pressure. In essence, an air pump controls the generated pressure by managing the air flow into and out of the system using valves. This mechanism enables accurate pressure regulation, guaranteeing the safe and efficient operation of various devices and systems reliant on compressed air.

- Q: Are air pumps suitable for inflating air mattresses with integrated air pumps?

- Yes, air pumps are suitable for inflating air mattresses with integrated air pumps. Integrated air pumps are designed to be used specifically with air mattresses and provide a convenient and efficient way to inflate them. These pumps are typically built into the mattress itself or can be attached to it, making it easy to inflate and deflate the mattress whenever needed. Air pumps, whether integrated or standalone, help in quickly and effortlessly filling up the mattress with air, saving time and effort compared to manual inflation methods. They ensure that the mattress is properly inflated to provide a comfortable sleeping surface. Therefore, using air pumps with integrated air pumps is a suitable and recommended method for inflating air mattresses.

- Q: How does an air pump handle different inflation pressure settings?

- An air pump is designed to handle different inflation pressure settings by adjusting the amount of air it pumps into an object based on the desired pressure level. This is usually achieved through the use of a pressure gauge or a digital display on the pump itself. When you set a specific pressure level on the pump, it will automatically monitor the current pressure inside the object and adjust the airflow accordingly. If the pressure is below the desired level, the pump will increase the airflow to inflate the object until it reaches the set pressure. On the other hand, if the pressure is above the desired level, the pump will decrease the airflow to prevent over-inflation and maintain the specified pressure. To achieve this, air pumps are equipped with various mechanisms like valves and regulators that control the airflow and pressure. These mechanisms ensure that the pump can accurately measure and adjust the inflation pressure based on the set level. In addition to manual pressure settings, some air pumps also have preset inflation options for specific objects like sports balls, bicycles, or inflatable mattresses. These presets are programmed to provide the optimal pressure level for each object, making it easier for the user to inflate them correctly without worrying about over or under-inflation. Overall, an air pump handles different inflation pressure settings by continuously monitoring and adjusting the airflow based on the desired pressure level, ensuring that the object being inflated is properly inflated without any damage or issues.

- Q: Can an air pump be used for cooling?

- No, an air pump cannot be used for cooling. Air pumps are typically used to inflate objects such as tires or inflatable toys by compressing air. Cooling requires a mechanism to remove heat, which an air pump lacks.

Send your message to us

250TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches