90TJ3 Ultra Light High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

90TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆The liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants.

◆It can pump fresh water or emulsion liquid similar like fresh water.

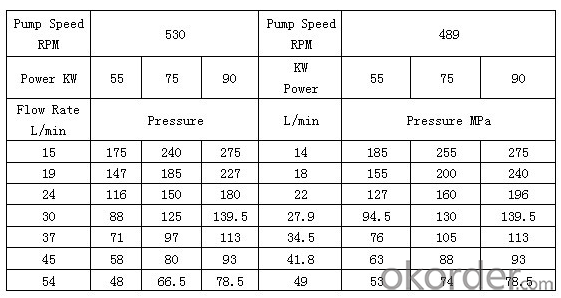

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Are there any health risks associated with using an air pump?

- Proper usage of an air pump generally does not carry significant health risks. However, it is important to be aware of a few potential concerns. Firstly, if the air pump is not cleaned or maintained adequately, it can become a breeding ground for bacteria and fungi. This can result in respiratory infections or allergies, particularly for individuals with pre-existing respiratory conditions like asthma. To reduce this risk, regular cleaning and sanitization of the air pump should be conducted according to the manufacturer's guidelines. Secondly, using the air pump in an area with poor ventilation can lead to an accumulation of carbon dioxide. Inhaling high levels of carbon dioxide can cause symptoms such as dizziness, headaches, and difficulty breathing. To prevent this, it is advisable to use the air pump in a well-ventilated space or ensure proper airflow. Furthermore, some air pumps may generate excessive noise levels that can be harmful in the long run. Extended exposure to loud noise can result in hearing damage or loss. To mitigate this risk, it is recommended to use hearing protection or select air pumps that operate at lower noise levels. Lastly, individuals with certain medical conditions, like high blood pressure or heart problems, should exercise caution when using an air pump. The physical exertion required to operate the pump can temporarily elevate heart rate and blood pressure. It is advisable for individuals with these conditions to consult their healthcare provider before utilizing an air pump. In conclusion, although there are potential health risks associated with using an air pump, they can be minimized by practicing good hygiene, ensuring adequate ventilation, protecting against noise exposure, and seeking guidance from a healthcare professional if necessary.

- Q: What is the maximum number of air outlets an air pump can support?

- The number of air outlets that an air pump can handle is determined by various factors, including the size and capacity of the pump, the pressure it can generate, and the overall design and construction of the pump. Normally, air pumps come with a predetermined number of outlets already built-in, usually ranging from 1 to 4 outlets. Nevertheless, it is possible to connect multiple air outlets to a single pump by using distribution bars or manifold systems. In these cases, the maximum number of outlets can vary depending on the specific setup. To determine the maximum number of air outlets that a particular air pump can support, it is always crucial to refer to the manufacturer's specifications and guidelines.

- Q: Can an air pump be used for inflatable conference displays?

- Yes, an air pump can be used for inflatable conference displays. Air pumps are commonly used to inflate various types of inflatables, including conference displays.

- Q: What are the common problems or malfunctions in air pumps?

- There are several common problems or malfunctions that can occur with air pumps. One of the most common issues is a clogged or blocked air intake or outlet. This can happen due to debris or dirt getting trapped in the pump, hindering the flow of air. Another common problem is a worn-out or damaged diaphragm or piston seal. Over time, these components can become brittle or develop cracks, causing air leaks or a decrease in pumping efficiency. Another common issue is a malfunctioning check valve. The check valve is responsible for preventing backflow of air, ensuring that the air only flows in one direction. If the check valve becomes faulty, it can cause air to escape back into the pump, reducing its effectiveness. Additionally, air pumps can experience motor failures or electrical issues, such as a burned-out motor or faulty wiring connections. These problems can result in the pump not turning on or not providing sufficient air pressure. Lastly, air pumps can also suffer from overheating. This can occur if the pump is operated continuously for extended periods without proper ventilation or if the pump is overloaded beyond its capacity. Overheating can lead to damage to internal components and cause the pump to malfunction or stop working altogether. Regular maintenance, including cleaning and lubricating the pump, can help prevent or alleviate some of these common problems. However, if any of these malfunctions occur, it is advisable to consult a professional or contact the manufacturer for guidance on how to resolve the issue.

- Q: Can an air pump be used for inflating camping gear?

- Yes, an air pump can be used for inflating camping gear. Many camping gear items such as air mattresses, inflatable pillows, and inflatable camping chairs require air to be filled. An air pump provides a convenient and efficient way to inflate these items. It can save time and effort compared to manually blowing them up with your mouth. There are different types of air pumps available for camping, including manual hand pumps, battery-operated pumps, and electric pumps. Depending on the size and type of camping gear, you can choose the appropriate air pump to ensure quick and easy inflation.

- Q: Can an air pump be used for inflating air cushions for wheelchairs?

- Yes, an air pump can be used for inflating air cushions for wheelchairs.

- Q: I bought a manual pump, I feel that the pump can not smoke, I do not know whether the use of the wrong way, or the gas pump is really useless, I hope that an expert pointing, thank you

- Method for using vacuum compressor pump:I. charging method:1. connect the pump to the 220V power supply.2. connect the inflatable fittings to the inflatable opening and turn on the switch to start charging ("-" means open, start charging, "O" means closing, stop inflating).3., pay attention to the inflatable valve should not be blocked, otherwise, the pump may be damaged by overheating.4., be careful not to use the air to inflate, please close to see our baby show in the suction port and inflatable mouth position.Two 、 evacuation method:1. open the air outlet for pumping the gas2. connect the right sized fittings to the suction port of the vacuum pump (if the suction port of the pump is just the right size, you don't need the three fittings). Connect the interface, then turn on the switch and start pumping ("-" means open, start pumping, "O" means "stop", "stop pumping").3., pay attention to the air valve should not be blocked, otherwise, the pump may be damaged by overheating.

- Q: How can the oxygen pump in the tank be out of oxygen, or pumping water, but without oxygen?

- There's a good chance you're out of gas. It's blocked up. Just get a wire through it......

- Q: Can an air pump be used for inflating inflatable slides with splash pools?

- Yes, an air pump can be used for inflating inflatable slides with splash pools. Air pumps are designed specifically for inflating objects such as inflatable slides, pools, and other inflatables. They provide a constant flow of air, which helps to quickly and efficiently inflate the slide and splash pool. It is important to ensure that the air pump is compatible with the specific type and size of the inflatable slide, as different models may require different levels of air pressure. Additionally, it is recommended to follow the manufacturer's instructions and safety guidelines when using an air pump to inflate inflatable slides with splash pools.

- Q: When the air pump starts, it seems that there is not enough strength, so the rhythm is very slow, and then it does not turn. It seems to be the owner of the card. That's the case. Thank you very much for the help of experienced people..

- If it's a belt drive, it must be a loose belt.

Send your message to us

90TJ3 Ultra Light High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches