Aluminum Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

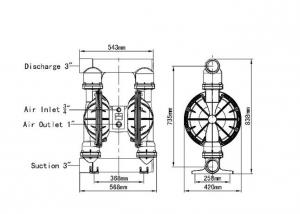

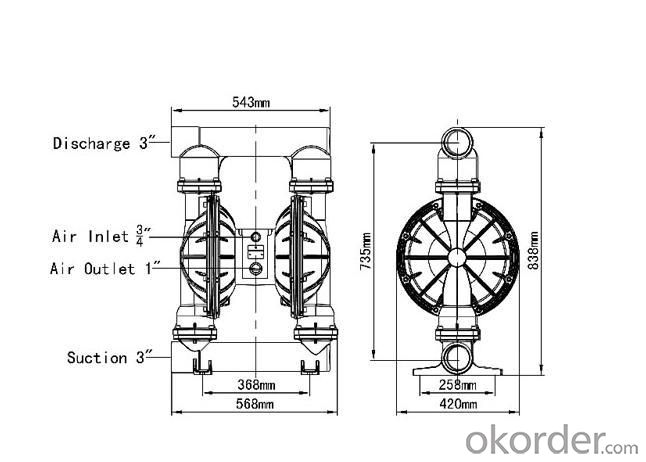

Details for Aluminum Diaphram Pump

1, Package and delivery of Aluminum Diaphram Pump

1) Packed with standard exporting wooden case, requested package will be acceptable.

2) Delivery date will be within 30 days after receiving the prepayment.

2, Technical specification of Aluminum Diaphram Pump

1) Connector type:2”.3”

2) Casing material:Aluminum alloy and stainless steel.

3) Max pressure psi(bar):100(6.9).

4) Max diameter of Suspended solid in(mm): 1/4" (6.4) PP20A; 3/8" (9.5) PP30A.

3, Model and specs details of Aluminum Diaphragm Pump.

|

|

PDP-8 |

PDP-10/15 |

PDP-20/25 |

PDP-25A |

PDP-32/40 |

PDP-50/65 |

PDP-80/100 |

PDP-125 |

|

Caliber ( mm) |

8 |

10/15 |

20/25 |

25 |

32/40 |

50/65 |

80/100 |

125 |

|

Fluid flow ( m³/h) |

0~1 |

0~1 |

0~3 |

0~7 |

0~9 |

0~21 |

0~34 |

0~60 |

|

Pressure ( bar) |

7 |

7 |

7 |

8.4 |

8.4 |

8.4 |

8.4 |

8.4 |

|

Head ( m) |

50 |

50 |

70 |

70 |

70 |

70 |

70 |

70 |

|

MAX. air consumption ( scfm) |

9.0 |

9.0 |

28 |

60 |

60 |

125 |

175 |

325 |

4, The advantages about our Powder Diaphram Pump

1) Four bolts connection with very round ball, well seal and good dry suction. The actual dry suction can reach to 4~7m.

2) High roundness valve ball for use the ball mill machine.

3) Three section manifold, Flexible installation and even can simultaneously convey two different liquids.

4) Longer diaphragm life. Diaphragm material from Dopont, Exxon.

5) Pilot type air valve, low maintenance, low air consumption, so the using cost is low.

6) Wetted body: PPH, PVDF, SS304, SS316, Aluminum etc.

7) Diaphragm: PTFE, Hytrel, Santoprene, Viton etc.

- Q: Can an air pump be used for inflating air mattresses with integrated pillows?

- Yes, an air pump can be used for inflating air mattresses with integrated pillows. An air pump provides a quick and efficient way to inflate air mattresses and the integrated pillows are no exception. By simply connecting the pump to the mattress's inflation valve, it will fill both the mattress and the integrated pillows with air. This not only saves time and effort compared to manual inflation, but it also ensures that the mattress and pillows are inflated to the desired level of comfort. Just make sure to use the appropriate nozzle or adapter that fits the inflation valve of the mattress in order to achieve a secure and airtight seal.

- Q: Truck air pump slowly

- First of all, the external inspection pipeline leaks, especially the gas reservoir and its pipeline1. install a pressure gauge in the air pump outlet to check the operation of the air pump.2, check the pressure regulating valve.3, check the distribution valve.Finally, check and adjust the power supply connection device of the air pump

- Q: Can an air pump be used for inflatable water hammocks?

- Yes, an air pump can be used to inflate inflatable water hammocks.

- Q: What is an oil-free gas pump?

- The oil-free air pump means that there is no lubrication between the piston and the cylinder of the air pump, and the piston ring and support ring are made of graphite containing material.

- Q: Can an air pump be used for inflating air fresheners?

- No, an air pump cannot be used for inflating air fresheners. Air fresheners do not require inflation as they are typically made of solid or gel-like materials that release fragrances into the air.

- Q: How does an air pump handle different air viscosities?

- An air pump is designed to handle different air viscosities by adjusting its pumping mechanism and ensuring the proper flow rate. The pump's motor and impeller are designed to provide enough power to overcome the resistance caused by the viscosity of the air. Additionally, manufacturers may incorporate features like variable speed control or multiple pumping stages to account for variations in air viscosity and maintain optimal performance.

- Q: What are the advantages of using an air pump over other inflation methods?

- Using an air pump instead of other inflation methods has several advantages. To begin with, air pumps are incredibly convenient and user-friendly. They are typically small and portable, allowing you to easily take them with you wherever you go. Whether you need to inflate a bike tire, a basketball, or an air mattress, an air pump can be operated quickly and effortlessly. Moreover, air pumps provide accurate and controlled inflation. Unlike manual pumps or blowing air into an object with your mouth, air pumps offer a consistent and regulated flow of air. This ensures that the object being inflated reaches the desired pressure without the risk of over or under inflation. Additionally, air pumps save time and effort. Inflating objects manually can be tiring and time-consuming, especially when dealing with larger items. On the other hand, air pumps can quickly and efficiently inflate objects, allowing you to conserve energy and complete the task more swiftly. Furthermore, using an air pump reduces the risk of contamination. When manually inflating objects, there is a chance that dirt, dust, or bacteria from your mouth or surroundings may enter the object. Air pumps eliminate this risk by providing a clean and sterile source of air, ensuring the inflated item remains hygienic. Lastly, air pumps are versatile and can be used for a wide range of objects. They can be utilized to inflate various items such as sports equipment, pool toys, inflatable furniture, and even car tires. This versatility makes them a valuable tool to have on hand for different situations and inflation needs. In conclusion, the advantages of using an air pump include convenience, precision, time-saving, cleanliness, and versatility. Whether for personal or professional use, an air pump offers numerous benefits over other inflation methods, making it the preferred choice for many.

- Q: Air pump paint has not stopped, after the pressure reached 0.8, a spray paint will be reduced to 0.6, the motor will start, so that has been non-stop to start charging

- This shows that your air compressor model selection is small, and your gun does not match, that is, the storage of air tank is small, it is recommended to change a larger point of the air compressor.

- Q: Why is the pipe hot when the car pumps the pump?

- Because the pressure is great, then the small pump, playing so much pressure will definitely heat,

- Q: What is the maximum altitude an air pump can operate at?

- The maximum altitude at which an air pump can operate depends on various factors such as the type of pump, its design, and the specific conditions it is subjected to. Generally, air pumps are designed to operate efficiently at lower altitudes where the air pressure is higher. As the altitude increases, the air pressure decreases, which can affect the performance of the pump. Different types of air pumps have different altitude limitations. For example, some electric air pumps may have a maximum altitude limit of around 5,000 feet (1,524 meters) above sea level. This is because their motors and mechanisms are designed to function optimally within a certain air pressure range. However, there are specialized air pumps, such as high-altitude air pumps, that are specifically designed to operate at higher altitudes. These pumps are engineered to overcome the reduced air pressure and maintain efficient performance at elevations exceeding 5,000 feet. Some high-altitude air pumps can operate at altitudes up to 12,000 feet (3,658 meters) or even higher. It is important to consult the manufacturer's specifications and guidelines for each specific air pump to determine its maximum altitude capability. Additionally, factors like temperature, humidity, and any modifications made to the pump can also impact its performance at higher altitudes. Ultimately, the maximum altitude at which an air pump can operate is determined by its design, capabilities, and the specific environmental conditions it is exposed to.

Send your message to us

Aluminum Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords