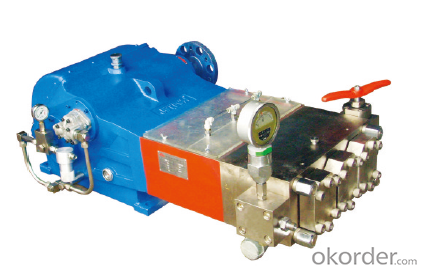

3D3Q-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

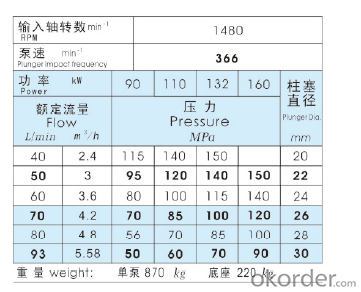

The technology for our high pressure pump was introduced from JETECH and the flow rate can reach 40L/min to 93L/min at the maximum pressure 150MPa, which is suitable for ultra-high pressure cleaning, metal exchanger, evaporation pot, and boiler cleaning in the sugar and power plant as well as various vessels and reactors. The medium to be pumped can be clean water, emulsion and some other chemical liquids.

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Can an air pump be used for inflating airships?

- Yes, an air pump can be used for inflating airships. Airships, also known as dirigibles or blimps, are filled with a gas lighter than air, such as helium or hydrogen, to generate buoyancy. The gas is typically stored in an envelope or balloon-like structure made of airtight materials. In order to inflate the airship, the gas needs to be pumped into the envelope. An air pump can be used to introduce the gas, either by directly transferring air into the envelope or by using the pump to compress and transfer the lighter-than-air gas, such as helium, from storage containers into the envelope. The pump must be capable of generating enough pressure to inflate the airship, and it should be designed to handle the specific gas being used. Additionally, the pump needs to be able to maintain a constant flow of gas to ensure proper inflation. Overall, while an air pump can be used for inflating airships, it is essential to consider the specific requirements of the airship and the gas being used to choose an appropriate pump for the task.

- Q: How does an air pump handle different air temperatures?

- Various mechanisms are utilized in the design of an air pump to handle different air temperatures. Firstly, the materials used in the components of the air pump are chosen for their ability to withstand extreme temperatures without compromising performance or integrity. This guarantees efficient operation of the pump, regardless of the air temperature. Moreover, air pumps often come equipped with built-in temperature regulation systems. These systems continuously monitor the air temperature and make adjustments to the internal mechanics as needed to maintain optimal performance. For instance, if the air temperature is extremely cold, the pump may increase the speed or power of its motor to account for the denser air. Conversely, if the air temperature is extremely hot, the pump may reduce its power output to prevent overheating or mechanical failure. Additionally, air pumps may incorporate insulation and heat dissipation mechanisms to cope with extreme air temperatures. Insulation helps to maintain a stable temperature for the internal components, preventing abrupt temperature fluctuations that could affect the functionality of the pump. Heat dissipation mechanisms, such as cooling fans or heat sinks, are employed to dissipate excess heat generated during operation, ensuring that the pump remains within a safe temperature range. In summary, the effective handling of different air temperatures by an air pump is achieved through the use of durable materials, temperature regulation systems, insulation, and heat dissipation mechanisms. These features collaborate to guarantee the reliable and efficient operation of the pump in various environmental conditions.

- Q: How reliable are air pumps?

- Air pumps are generally reliable and efficient devices for inflating various objects, such as tires, sports equipment, and inflatable toys. However, their reliability can vary depending on the brand and quality of the pump. It is important to choose a reputable brand and ensure proper maintenance and usage to maximize the pump's reliability and lifespan.

- Q: What is the average lifespan of an air pump under regular use?

- The average lifespan of an air pump under regular use can vary depending on various factors such as the brand, quality, maintenance, and usage patterns. However, on average, a well-maintained air pump can last between 3 to 5 years under regular use.

- Q: Can an air pump be used for inflating air mattresses with built-in temperature control?

- Indeed, an air pump is capable of inflating air mattresses equipped with built-in temperature control. The main purpose of an air pump is to supply air to the mattress, regardless of any supplementary features such as temperature regulation. The temperature control mechanism integrated within the air mattress is an independent system that manages the air temperature within the mattress. The air pump's duty is solely to inflate the mattress, whereas the temperature control system ensures comfort by adjusting the air temperature. Consequently, one can certainly utilize an air pump to inflate an air mattress equipped with built-in temperature control.

- Q: Can an air pump be used for inflatable promotional items?

- Indeed, inflatable promotional items can be easily inflated using an air pump. In fact, utilizing an air pump is considered one of the most effective and convenient techniques for inflating promotional items such as balloons, inflatable characters, or banners. By employing an air pump, a constant and controlled flow of air is provided, allowing for quick and effortless inflation. Moreover, the use of an air pump guarantees that the promotional items are inflated to their desired shape and size. Furthermore, relying on an air pump eliminates the need for manual blowing, which can be both exhausting and time-consuming, particularly when inflating multiple items. All in all, an air pump is an indispensable tool for effectively inflating and maintaining the appearance of inflatable promotional items.

- Q: Can an air pump be used for scuba diving?

- No, an air pump cannot be used for scuba diving. Scuba diving requires the use of a specialized breathing apparatus known as a scuba tank, which is filled with compressed air or a gas mixture specifically designed for diving. An air pump, on the other hand, is typically used to inflate objects such as tires or balloons by compressing atmospheric air. The air produced by an air pump is not suitable for breathing underwater as it does not provide the necessary oxygen levels required for scuba diving. Additionally, scuba tanks are designed to withstand the high pressures experienced underwater, whereas air pumps are not built to withstand such conditions. Therefore, it is essential to use the appropriate equipment, such as a scuba tank, when engaging in scuba diving activities for the safety and well-being of the diver.

- Q: Can an air pump be used for bouncy castles or inflatable toys?

- Yes, an air pump can be used for bouncy castles or inflatable toys. In fact, it is the most common and efficient way to inflate them. An air pump provides a steady stream of air that can quickly and easily fill up the inflatable structure. It is designed specifically for this purpose, with the right amount of pressure and nozzle attachments to fit the valves of bouncy castles and inflatable toys. Using an air pump ensures a safe and proper inflation, making the bouncy castle or inflatable toy ready for use in no time.

- Q: How long does it take for an air pump to inflate an average-sized tire?

- The duration required for an air pump to inflate an average-sized tire can differ based on various factors, including the air pump's type, power, the initial pressure of the tire, and the desired final pressure. On average, it generally takes approximately 3 to 5 minutes for an air pump to completely inflate an average-sized tire. It is crucial to acknowledge that this is merely an approximation, and the actual duration may differ.

- Q: Why is the pipe hot when the car pumps the pump?

- Because the pressure is great, then the small pump, playing so much pressure will definitely heat,

Send your message to us

3D3Q-S Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches