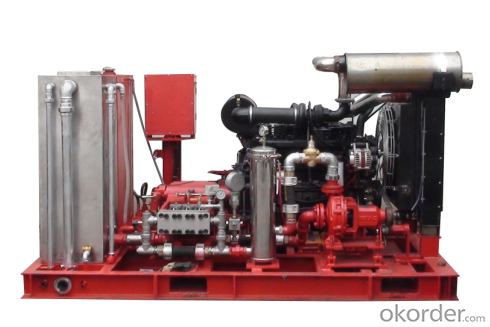

200TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

200TJ3 is a type of ultra high pressure pump of JETECH technology (an American company).

This type is of various favorable features, such as light weight, compact structure, small size, high efficiency.

◆The power end case is precisely machined. The power end is force lubricated, transmitted stably and reliably by low friction herringbone gear mechanism, with less temperature increase, suitable for long time operation.

◆Liquid end is produced based on American technology, easy for maintenance and repair, able to work in long time.

◆This pump is applicable in ultra high pressure water cleaning, metal cutting, ship cleaning, rust removal, all kinds of tanks, containers, vessels, evaporators, heat exchangers cleaning in chemical, sugar, and power plants. It can pump fresh water or emulsion liquid similar like fresh water.

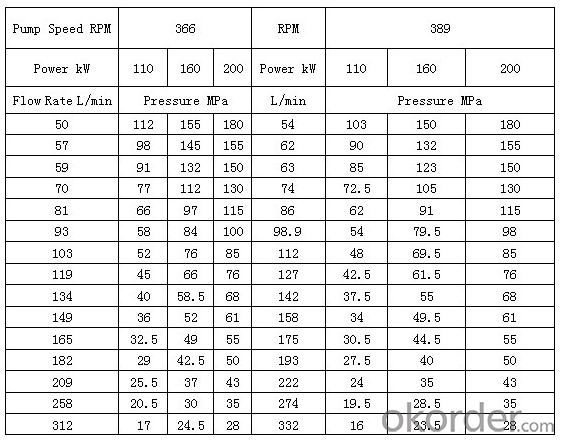

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: Are air pumps suitable for medical oxygen therapy?

- Air pumps are indeed appropriate for medical oxygen therapy. In medical environments, air pumps are frequently employed to provide additional oxygen to patients facing breathing difficulties or inadequate oxygen levels. These pumps are specifically designed to administer a regulated stream of oxygen to the patient via a mask or nasal cannula, thereby enhancing oxygenation and easing symptoms of respiratory distress. To guarantee a constant and trustworthy supply of medical-grade oxygen, air pumps are often utilized alongside other medical apparatus, such as oxygen concentrators or liquid oxygen systems. It is crucial to acknowledge that the usage and dosage of oxygen therapy with air pumps should be guided and supervised solely by healthcare professionals.

- Q: Width 31cm~~ high 19cm

- That's ok! It is feasible and ideal to use the smallest waterfall type plug-in filter.Waterfall type plug-in filter has several features:1: do not occupy space.2: cleaning, replacement of filter materials, convenient and quick.3: Although the water flow is softer, the water area can be wide and even.Therefore, the use of minimum power cascade type plug-in filter is the best choice, one machine multi-purpose, that is to solve the problem of water filtration, but also eliminates the embarrassment of hypoxia.You don't have to think about the oxygen content of such a small aquarium. As long as there aren't many fish in the range, a waterfall plug-in filter is enough. The flow of water can play a certain role in increasing oxygen. So, in this respect, your choice is the best! There are some details that may need to be reminded:1: do not feed the fish diet, average daily feeding time, the amount of time is 1----2 minutes after prevail.2: do not blindly use aquatic products, such as: related to other agents, all kinds of nitrifying bacteria, fish medicine... And other stuff...3: please do not change the water, the average 15----30 for 50% days on the line, and then slowly add new water on the line, pay attention to the day before, do not change the water fish, changing the water before all relevant power broken especially the heating rod; we must advance at least 10 minutes break, should pay attention to the new temperature the old water water.

- Q: How does an air pump prevent water freezing in pipes during winter?

- An air pump prevents water freezing in pipes during winter by introducing a flow of warm air into the pipes. The pump is connected to the pipes and forces air through them, displacing any water and preventing it from stagnating and freezing. The continuous flow of air helps to maintain the temperature above freezing point, ensuring that the water remains in a liquid state. Additionally, the movement of air aids in breaking up any ice formations that may have started to form, preventing blockages and subsequent pipe bursts. By keeping the pipes clear of ice, an air pump helps to protect them from damage and maintain a steady water supply during the winter season.

- Q: The compressor power of the refrigerator is too small, even if the air storage tank is mounted, the nail gun can be driven to work, and the bicycle can be pumped up.

- The air compressor of the refrigerator can do. But it's very slow charge it will delay things very hard ah, I suggest to buy an old

- Q: How does an air pump prevent condensation in enclosed spaces?

- Condensation in enclosed spaces can be prevented by using an air pump to increase air circulation and flow. If the air remains stagnant or does not circulate properly, moisture in the air will accumulate on surfaces and cause condensation. However, an air pump prevents this by keeping the air moving and preventing moisture buildup. The air pump creates increased airflow, constantly replacing moist air with drier air, which reduces the chances of condensation forming on surfaces. Furthermore, the movement of air helps to evenly distribute heat throughout the space, further decreasing the likelihood of condensation. In conclusion, an air pump effectively prevents condensation by improving air circulation and maintaining balanced humidity levels in enclosed spaces.

- Q: What is the maximum size of air pump available?

- The maximum size of an air pump available can vary depending on the specific brand, model, and purpose. However, industrial air pumps can be quite large, reaching sizes of several meters in height and width, while smaller portable air pumps can be as compact as a few inches. It ultimately depends on the intended use and requirements of the user.

- Q: How does an air pump maintain a constant pressure?

- A variety of mechanisms and components enable an air pump to uphold a steady pressure. The pressure sensor is one such mechanism, consistently monitoring the pressure level within the pump. If the pressure falls below the desired level, the pump activates and compresses air to increase the pressure. Once the pressure reaches the desired level, the pump automatically shuts off to prevent excessive pressurization. Another component that aids in maintaining constant pressure is the pressure relief valve. This valve opens when the pressure surpasses a specific threshold, allowing excess air to escape and preventing the pressure from exceeding safe limits. This ensures that the pressure remains within the desired range, safeguarding the pump and the system it supplies air to. Additionally, air pumps often incorporate a pressure regulator, which empowers the user to establish and maintain a precise pressure level. The regulator governs the flow of air entering or exiting the pump, regulating the pressure according to the user's requirements. In summary, an air pump can effectively sustain a constant pressure by continuously monitoring and adjusting the air flow within the desired range, thanks to pressure sensors, relief valves, and regulators.

- Q: Can an air pump be used for powering pneumatic tools?

- Indeed, the utilization of an air pump is viable for the activation of pneumatic tools. These tools, also recognized as air tools, are specifically designed to operate with the aid of compressed air. By means of an air pump, such as a compressor, compressed air is generated and can be either stored in a tank or directly employed to energize these tools. Through a hose, the compressed air is supplied to the pneumatic tool, propelling the tool's piston or turbine, thus enabling it to execute diverse tasks. Air pumps are widely employed within industries, workshops, and construction sites to energize a vast array of pneumatic tools, encompassing nail guns, impact wrenches, sanders, drills, and spray guns.

- Q: Can an air pump be used for inflatable pool toys?

- Yes, an air pump can be used for inflatable pool toys. Air pumps are designed to inflate various objects, including pool toys such as inflatable rafts, floats, and tubes. Using an air pump makes the process of inflating pool toys faster and more convenient, as opposed to manually blowing them up. Air pumps typically come with different nozzle attachments to fit different valves on pool toys. It is important to ensure that the air pump has the correct nozzle size and pressure capacity to inflate the specific pool toy properly.

- Q: How powerful should an air pump be for inflating car tires?

- Several factors determine the effectiveness of an air pump in inflating car tires. The foremost requirement is its ability to generate ample pressure to fill the tires according to the car manufacturer's recommended PSI value. This information is typically available on a sticker located inside the driver's side door jamb or in the car's manual. Generally, car tires necessitate a pressure ranging from 30 to 35 PSI, although this can vary based on the make and model. Consequently, the air pump should possess a maximum pressure output exceeding this range to handle any tire inflation requirements. A reliable guideline is to select an air pump with a maximum pressure output of at least 100 PSI, as this will supply adequate power to inflate tires of various sizes. Moreover, the air pump should exhibit a sufficient airflow rate or volume per minute (CFM) for swift tire inflation. While a higher CFM rating guarantees faster inflation, it is not necessarily critical for regular car tire inflation. A moderate CFM rating of approximately 2-3 CFM should suffice for most car tire inflation purposes. It is crucial to consider the power source of the air pump as well. Numerous options are available, such as 12V DC powered pumps that connect to the car's cigarette lighter socket or portable models that utilize rechargeable batteries. The chosen power source should be convenient and suitable for the intended usage. In conclusion, an air pump for inflating car tires should possess a maximum pressure output of at least 100 PSI and a moderate CFM rating of around 2-3 CFM. This will ensure that it can handle the recommended PSI range for car tires and provide efficient inflation.

Send your message to us

200TJ3 Type Ultra High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches