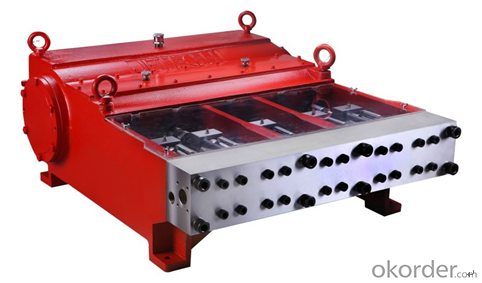

500TJ3 Type Large Flow High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

500TJ5 is of much advantages, such as good appearance, large flow, high pressure, reliability, low noise, small pulse, slow pump speed, stable operation, simple maintenance, low friction, high lubrication ability, low temperature increase in power end, long operation time.

◆The liquid end is based on American advanced technology, with perfect structure design, simple maintenance, and reliable operation.

◆It is applicable in high pressure water leaning, metallurgy descaling, oil, test platform etc. It can pump fresh water up to 50°C, emulsionand chemical liquid similar like fresh water. It can be driven by malfunction power source.

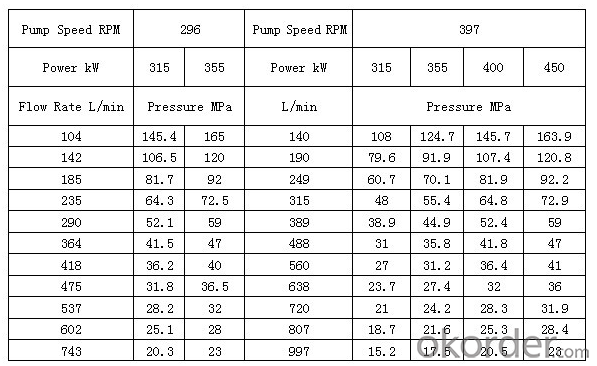

◆Technology Parameters

Our company is the drafting company of the Chinese high pressure pump Industry Standard.

Our products have a wide range of applications, such as

1. Industrial pipe cleaning

2.Shipyard rust removal, paint removal

4.Aviation: expansion joints, grease, rubber and hydraulic fluid on runways cleaning.

5.hydropower station/ dam/dike concrete work treating.

6.Casting clean scale removal rust removal paint, removal sand.

7. Pipe pressure test, hose pressure test, hydro pressure test, etc.

Our company has passed European CE Certificate, ISO9001:2000 certificate,ISO 14001:2004 certificate, and AAA Credit Rating Certificate. It’s a member of Waterjet Technology Association (WJTA) in USA and National Standarlization

- Q: What is the power consumption of an air pump?

- The power consumption of an air pump can vary based on several factors, including the pump's size and type, as well as its specific application. Generally, air pumps are designed to be energy-efficient and consume relatively low amounts of power compared to other electrical devices. To measure the power consumption of an air pump, watts (W) or sometimes kilowatts (kW) are typically used. Smaller air pumps, like those for fish tanks or small inflatable items, usually have power ratings ranging from 5W to 20W. These pumps can operate continuously or intermittently and are typically connected to a standard electrical outlet. On the other hand, larger air pumps, used for industrial or commercial purposes, can have power ratings ranging from 100W to several kilowatts. These pumps can generate higher air pressures and flow rates, necessitating more power for operation. They are often connected directly to higher voltage electrical systems to accommodate their power needs. It's important to note that other factors can also influence the power consumption of an air pump, including the air pressure or volume it produces, the motor's efficiency, and any additional features or functionalities it possesses. Therefore, it's always advisable to consult the manufacturer's specifications or user manual for accurate information about a specific air pump model's power consumption.

- Q: What is the recommended air pressure for different types of inflatables?

- The recommended air pressure for different types of inflatables can vary depending on the specific item. However, as a general guideline, here are some recommendations for common inflatables: 1. Pool floats and inflatable toys: These typically require a lower air pressure, usually around 1-2 PSI (pounds per square inch). It is important to avoid over-inflating them as it can put strain on the seams and lead to damage. 2. Air mattresses: Most air mattresses recommend an air pressure of around 6-8 PSI. However, it is essential to check the specific instructions provided by the manufacturer, as some models may have different requirements. 3. Balloons: Regular latex balloons usually require an air pressure of around 0.5 PSI. Over-inflating balloons can cause them to burst, so it is crucial to follow the recommended guidelines. 4. Inflatable boats and kayaks: The air pressure for these types of inflatables can vary depending on the size and material. Generally, the recommended range is between 2-3 PSI, but it is essential to consult the manufacturer's instructions for accurate guidelines. 5. Gym/exercise balls: The recommended air pressure for gym or exercise balls can vary depending on the size and intended use. As a general rule, most exercise balls require an air pressure of around 4-5 PSI. However, it is crucial to verify the specific instructions provided by the manufacturer. Remember, these recommendations are general guidelines, and it is always best to consult the manufacturer's instructions for accurate and specific air pressure recommendations for your particular inflatable item. Over-inflating or under-inflating can impact the performance, durability, and safety of the inflatable, so it is crucial to follow the recommended guidelines.

- Q: What is the recommended air pressure for inflatable dinghies?

- The recommended air pressure for inflatable dinghies can vary depending on the specific make and model of the dinghy. However, as a general guideline, most manufacturers recommend inflating the dinghy to a pressure between 2 and 3 pounds per square inch (psi). It is important to check the manufacturer's instructions or the dinghy's user manual for the specific recommended air pressure. Overinflating the dinghy can lead to issues such as seam stress, decreased stability, and potential damage or puncture. Underinflating the dinghy, on the other hand, can result in decreased performance, poor maneuverability, and reduced buoyancy. It is advisable to use a reliable pressure gauge to ensure that the dinghy is inflated to the correct pressure.

- Q: Are air pumps suitable for emergency use?

- Yes, air pumps are suitable for emergency use. Air pumps are highly versatile and can be used in a variety of emergency situations. For example, in the case of a flat tire or a deflated inflatable boat, an air pump can quickly inflate the tire or boat, allowing for quick transportation or rescue. Additionally, air pumps can also be used in medical emergencies, such as providing oxygen to patients who are experiencing difficulty breathing. Overall, air pumps are a reliable and efficient tool that can be used in emergency situations to provide quick and necessary assistance.

- Q: I bought a 10 dollar single oxygen pump today. It's plugged in. How can I use it properly? Is it going to be open day and night? Will it burn out?!

- The gas outlet pipe is connected with a pneumatic stone and is placed at the bottom of the cylinder. The pump is hung outside the cylinder for.24 hours, and the normal service life is about 3 to 5 years

- Q: What is the maximum pressure limit of an air pump?

- The maximum pressure limit of an air pump can vary depending on the specific model and purpose of the pump. However, in general, air pumps can have maximum pressure limits ranging from a few PSI (pounds per square inch) to several thousand PSI. For example, a portable air pump used for inflating tires or sports equipment may have a maximum pressure limit of around 150 PSI. This is typically sufficient for most everyday applications. On the other hand, industrial air compressors used in manufacturing or construction may have much higher maximum pressure limits. These compressors can reach pressures of several thousand PSI to power heavy machinery or operate pneumatic tools. It is important to consult the manufacturer's specifications or user manual to determine the exact maximum pressure limit of a specific air pump. Operating an air pump beyond its maximum pressure limit can result in equipment damage, safety hazards, or even catastrophic failures.

- Q: How does an air pump handle different air densities at different altitudes?

- To maintain optimal performance, an air pump is designed to handle varying air densities at different altitudes by adjusting its operational parameters. As the altitude increases, the atmospheric pressure decreases, causing a decline in air density. In order to compensate for this change, an air pump employs different mechanisms to ensure efficient operation. One method used by air pumps to handle different air densities is by adjusting the speed or rotation rate. By increasing the speed, the pump can offset the lower air density and maintain a consistent flow rate. This adjustment is typically done automatically, with sensors monitoring the air density and making necessary speed adjustments. Another approach employed by air pumps involves the use of variable geometry impellers or diffusers. These components have the capability to alter their shape or size to adapt to varying air densities. By modifying the impeller's shape or angle, the pump can optimize performance and maintain a consistent flow rate, regardless of altitude. Moreover, air pumps may incorporate electronic controls and sensors to monitor and adjust their operation based on the air density at a particular altitude. These sensors gather data on factors like temperature, pressure, and humidity, which are then used to calculate the air density. The pump's control system uses this information to automatically adjust parameters such as speed, impeller shape, or other relevant settings. In conclusion, an air pump handles different air densities at different altitudes by adjusting its operational parameters. This can be achieved through changes in speed or rotation rate, the utilization of variable geometry impellers or diffusers, and the incorporation of electronic controls and sensors. These mechanisms work together to ensure that the air pump maintains optimal performance and a consistent flow rate, regardless of the altitude.

- Q: Can an air pump be used for inflating inflatable obstacle courses?

- Yes, an air pump can be used for inflating inflatable obstacle courses.

- Q: Are air pumps easy to use?

- Yes, air pumps are generally easy to use. They are designed to be user-friendly and require minimal effort to operate. Most air pumps come with clear instructions on how to use them, and the process typically involves attaching the pump to the item that needs to be inflated, such as a bicycle tire or an inflatable mattress, and then pumping air into it using either a manual or an electric pump. The level of difficulty may vary depending on the type of pump and the specific item being inflated, but in general, air pumps are designed to be straightforward and convenient to use.

- Q: How does an air pump affect water temperature in fish tanks?

- The water temperature in fish tanks is not directly influenced by an air pump. The primary purpose of an air pump is to supply oxygen to the water through water movement and surface agitation. This aids in keeping the fish healthy by facilitating gas exchange at the water's surface, preventing stagnant water, and ensuring sufficient oxygen levels for the fish to breathe. Nevertheless, the air pump can have an indirect impact on the water temperature in a few ways. Firstly, the air bubbles generated by the pump can result in slight evaporation, leading to a minor decrease in water temperature. Additionally, the water movement caused by the air pump can improve the distribution of heat within the tank, preventing uneven hot and cold spots and promoting a more uniform temperature throughout. Furthermore, certain air pumps are designed to be connected to air stones or diffusers. These devices can be attached to a heater, assisting in the even distribution of heat throughout the tank. By utilizing an air pump in conjunction with a heater, the temperature gradient in the tank can be minimized, creating a more stable and suitable temperature range for the fish. In conclusion, although an air pump does not directly affect the water temperature in fish tanks, it plays a vital role in maintaining oxygen levels and water circulation, indirectly contributing to a more stable and suitable temperature environment for the fish.

Send your message to us

500TJ3 Type Large Flow High Pressure Plunger Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches