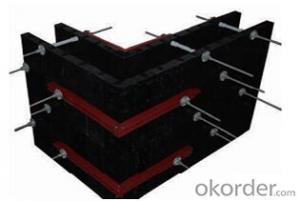

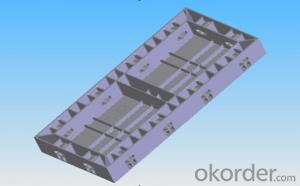

Plastic concrete panel and plastic concrete formwork, plastic formwork for concrete

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic concrete panel and plastic concrete formwork, plastic formwork for concrete

Saving your time, money and energy !!!

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

Product Photos/ Plastic concrete panel and plastic concrete formwork

FAQ:

1.Q:Are you a factory or trading company?

A: We are a factory of plastic formwork.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Taizhou City, China.You can fly to Ningbo airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get some samples?

A: We are honored to offer you samples.

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISOTS16949 authentication.

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price, if you have drawings, we can help you caculate the quantity of plastic formwork .

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template construction is convenient, high efficiency: aluminum alloy building template system assembly is simple, convenient, average weight 30KG / m2, completely assembled by the artificial, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer Easy to install), skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold workers only need to install wood workers 70-80%, and do not need skilled workers, just install Before the construction of the staff can be a simple training can be).

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- The quality of the template is related to the quality of concrete engineering. The key lies in the accurate size, the assembly is firm, the patchwork is tight and the assembly and disassembly is convenient. Should be based on the structure of the form and characteristics of the appropriate form of template, in order to achieve good technical and economic results.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- Can be ruled length processing, can be ruled length processing, can be ruled length processing

Send your message to us

Plastic concrete panel and plastic concrete formwork, plastic formwork for concrete

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords