plastic concrete formwork better than doka formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Plastic construction formwork

plastic concrete formwork better than doka formwork

Saving your time, money and energy !!!

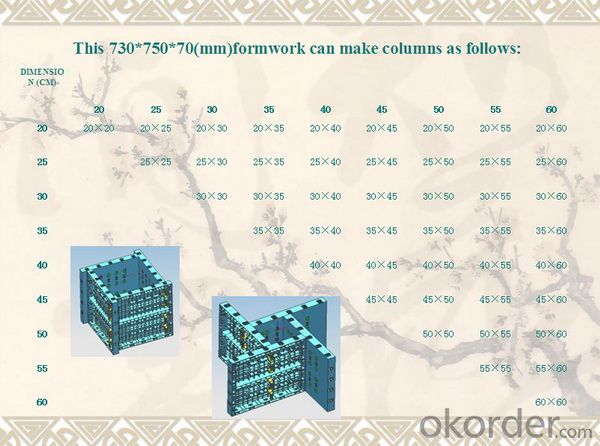

What is Details of our products plastic concrete formwork ?

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

What is Advantages of our company ?

Our anvantages

| High quality |

Reasonable price | |

| Strict delivery time | |

| Good after-sales service | |

Profession maker for 21 years | |

Gold supplier 9th year | |

Strict quality control | |

| professional injection mould | |

| 3D design |

Product Photos/ plastic concrete formwork

FAQ:

1.Q:Are you a factory or trading company?

A: We are the factory of plastic formwork.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Taizhou City, China.You can fly to Ningbo airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get some samples?

A: We are honored to offer you samples.

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISOTS16949 authentication.

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price, if you have drawings, we can help you caculate the quantity of plastic formwork .

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Stupid way, with a little hammer little bit of the beat, out a little less a little bit.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- The quality of the building template is relatively strong, compared to the cost is also higher. hope this helps!

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- First, smooth and smooth. Temporarily stitching the stencil, the surface quality of the concrete structure after the demolding, the finish are more than the technical requirements of the existing water template, no need to plaster twice, the province of materials.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

plastic concrete formwork better than doka formwork

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords