Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Whole Steel Formwork Description

CMAX Whole Steel Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort. 55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Construction Steel Formwork

- Simple structure, high loading capacity.

- Light weight, easy assemble.

- Excellent surface quality of formed concrete.

- We can special design according to any requirements.

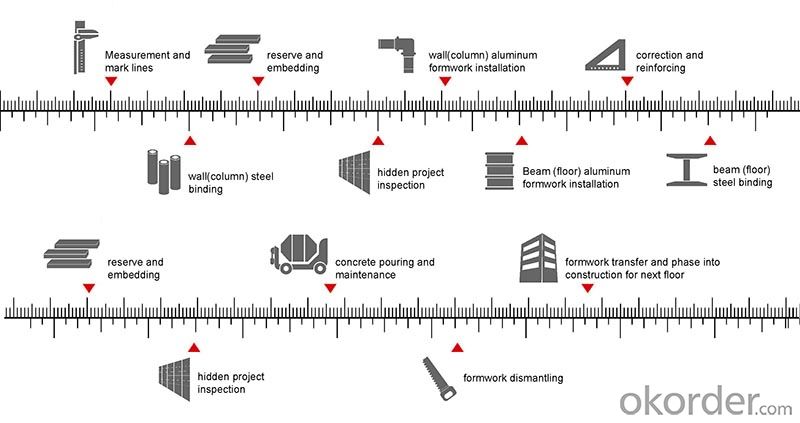

3. Construction Process

4. FAQ of Steel Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: Can steel formwork be used for both above-water and underwater structures?

- Yes, steel formwork can be used for both above-water and underwater structures. Steel formwork is known for its durability, strength, and resistance to corrosion, which makes it suitable for various construction applications. It can withstand the water pressure and provide a stable framework for both above-water and underwater structures.

- Q: Can steel formwork be used for bridge construction projects?

- Bridge construction projects can indeed utilize steel formwork. This versatile and durable solution is often favored for its high strength and ability to bear heavy loads. Steel formwork establishes a strong framework capable of withstanding the weight and pressure exerted by concrete during construction. There are several advantages to using steel formwork for bridge construction. Firstly, it can be easily customized and fabricated to achieve the desired shape and size, ensuring precise and efficient construction. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for bridge projects. Moreover, the use of steel formwork guarantees a smooth and even finish on the bridge structure, resulting in a high-quality end product. Steel formwork also allows for the incorporation of various features, such as recesses and openings, which are often crucial in bridge construction. In conclusion, steel formwork is a suitable choice for bridge construction due to its strength, durability, and ability to provide precise and uniform finishes.

- Q: How does steel formwork improve the quality of concrete structures?

- Steel formwork is widely used in the construction industry due to its numerous advantages, including its ability to significantly improve the quality of concrete structures. Here are some ways in which steel formwork enhances the quality of concrete structures: 1. Better Form Stability: Steel formwork provides superior form stability compared to traditional wooden formwork. It is more rigid and less prone to warping or distortion, ensuring that the concrete is poured into a precise and consistent shape. This results in straighter walls, smoother surfaces, and overall better structural integrity. 2. Increased Durability: Steel formwork is highly durable and can withstand the harsh conditions of the construction site. It does not rot, decay, or get damaged easily, unlike wooden formwork. Its long lifespan ensures that it can be reused multiple times, reducing costs and waste. This durability translates into stronger and longer-lasting concrete structures. 3. Accurate Dimensions: Steel formwork is manufactured with high precision, allowing for accurate and consistent dimensions in the concrete structures. It helps in achieving the desired shape, size, and alignment of the elements. This accuracy is crucial in ensuring that the structure meets the required specifications and architectural designs, resulting in a high-quality finished product. 4. Improved Surface Finish: Steel formwork provides a smooth and even surface finish to the concrete structures. The steel panels are designed to minimize surface imperfections and prevent leakage of the concrete mixture. This results in a visually appealing structure with a uniform finish, reducing the need for additional plastering or finishing work. 5. Enhanced Safety: Steel formwork offers increased safety during the construction process. Its sturdy and rigid nature provides a stable platform for workers to pour and work with the concrete. The risk of accidents, such as formwork failure or collapse, is significantly reduced with steel formwork, ensuring the safety of workers and the integrity of the structure. Overall, the use of steel formwork in concrete construction brings several benefits that contribute to the improvement of the quality of the structures. With its form stability, durability, accurate dimensions, improved surface finish, and enhanced safety, steel formwork plays a crucial role in ensuring the integrity, aesthetics, and longevity of concrete structures.

- Q: Are there any specific maintenance requirements for steel formwork?

- Yes, steel formwork requires regular maintenance to ensure its durability and optimal performance. Some specific maintenance requirements for steel formwork include cleaning, removing concrete residue, inspecting for any signs of damage or corrosion, and applying protective coatings to prevent rust. Additionally, proper storage and handling practices should be followed to prevent any deformation or bending of the steel formwork components.

- Q: Can steel formwork be used for foundation walls?

- Yes, steel formwork can be used for foundation walls. Steel formwork is a durable and strong material that provides excellent support for concrete during the construction process. It can be used for both horizontal and vertical applications, including foundation walls. Steel formwork offers several advantages such as high load-bearing capacity, reusable nature, and ease of installation and removal. It allows for precise shaping of foundation walls and ensures a smooth and uniform finish. Additionally, steel formwork is resistant to moisture and can withstand harsh weather conditions, making it suitable for foundation walls in various environments.

- Q: What is the expected lifespan of steel formwork ties?

- The expected lifespan of steel formwork ties can vary depending on several factors such as the quality of the steel used, the conditions in which they are used, and how well they are maintained. However, in general, steel formwork ties are designed to have a long lifespan and can often be reused multiple times. High-quality steel formwork ties that are properly maintained and used in appropriate conditions can last for several years. With regular cleaning, inspection, and maintenance, they can be reused for multiple construction projects, which helps to reduce costs and waste. However, it is important to note that steel formwork ties can deteriorate over time, especially if they are exposed to harsh environmental conditions or corrosive substances. Therefore, it is crucial to regularly inspect the ties for any signs of damage or corrosion and replace them if necessary. Additionally, proper storage and handling of the ties when not in use can also help extend their lifespan. In conclusion, while there is no fixed lifespan for steel formwork ties, with proper maintenance and care, they can last for several years and be reused multiple times, making them a cost-effective and sustainable option for construction projects.

- Q: How does steel formwork improve construction site safety?

- Steel formwork improves construction site safety in several ways. Firstly, steel formwork is strong and durable, providing a stable and secure structure for workers to perform their tasks. This reduces the risk of accidents or collapses that could result in injuries. Additionally, steel formwork can be easily assembled and disassembled, minimizing the time workers spend on potentially hazardous activities such as scaffolding. Moreover, steel formwork is fire-resistant, reducing the risk of fire-related incidents on construction sites. Overall, the use of steel formwork enhances construction site safety by providing a reliable and stable framework for workers to carry out their tasks efficiently and securely.

- Q: What are the different cost considerations associated with steel formwork?

- Some of the cost considerations associated with steel formwork include the initial purchase or rental cost of the formwork system, transportation and handling costs, installation and dismantling costs, maintenance and repair costs, and the potential for reusability and long-term cost savings compared to other formwork materials.

- Q: Is steel formwork suitable for projects with heavy concrete loads?

- Yes, steel formwork is highly suitable for projects with heavy concrete loads. Steel formwork is known for its strength, durability, and load-bearing capacity, making it ideal for projects that involve heavy concrete loads. Steel formwork can withstand the pressure and weight of the concrete, ensuring that it maintains its shape and integrity throughout the pouring and curing process. Additionally, steel formwork offers excellent dimensional accuracy, allowing for precise and consistent concrete placement, which is crucial for projects with heavy loads. Overall, steel formwork is a reliable and robust choice for projects that require the support of heavy concrete loads.

- Q: Can steel formwork be used for curved or irregularly shaped structures?

- Yes, steel formwork can be used for curved or irregularly shaped structures. Steel formwork is highly flexible and can be easily customized to match the desired shape or form of the structure. Its strength and durability make it suitable for various construction projects, including those that involve unique or unconventional designs.

Send your message to us

Light Duty Whole Steel Formwork for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches