Heavy Duty Whole Steel Formwork for Bridge Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Heavy Duty Whole Steel Formwork

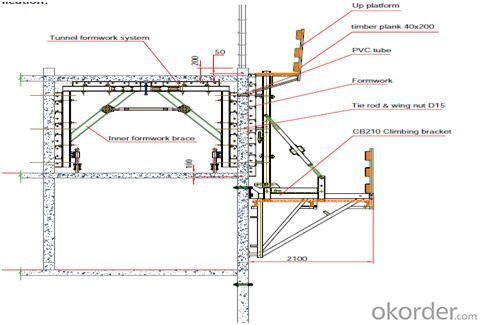

A compositional steel formwork system mainly used in the building which has regular structure without beams, the excellent formwork system can make the integral pouring for the wall & slab easily achieved.

2. Main Features of Heavy Duty Whole Steel Formwork

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

◆ No assembling, easy operation with formed formwork.

◆ High stiffness, make perfect shape for concrete.

◆ Repeatedly turnover is available.

◆ Widely applied range, such as building, bridge, tunnel, etc.

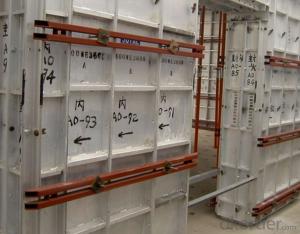

3. Heavy Duty Whole Steel Formwork images

4. Heavy Duty Whole Steel Formwork Specifications

5. FAQ of Heavy Duty Whole Steel Formwork

1) What can we do for you?

.We can ensure the quality of the Heavy Duty Whole Steel Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: How does steel formwork affect the structural integrity of a building?

- Steel formwork can greatly enhance the structural integrity of a building. Its rigid and durable nature ensures accurate and consistent placement of concrete, resulting in a stronger and more reliable structure. The use of steel formwork also allows for greater flexibility in design, enabling complex architectural features and reducing the need for additional support elements. Overall, steel formwork plays a crucial role in ensuring that a building maintains its structural stability and meets the required safety standards.

- Q: Can steel formwork be used for stadium construction projects?

- Yes, steel formwork can be used for stadium construction projects. Steel formwork is a versatile and durable solution that can withstand the heavy loads and complex structural requirements of stadium construction. It provides the necessary strength and support for casting concrete in large and intricate shapes, ensuring a robust and long-lasting stadium structure.

- Q: What are the different types of safety systems used with steel formwork?

- Steel formwork commonly utilizes various safety systems to ensure worker safety and prevent accidents on construction sites. Some frequently employed safety systems for steel formwork comprise: 1. Guardrails: These are often positioned along the edges of the formwork to avert workers from slipping or falling. Constructed from steel or aluminum, they possess the capacity to withstand a specific amount of force. 2. Safety harnesses: Workers wear safety harnesses, which are fastened to a secure anchor point to prevent falls. These harnesses are typically adjustable to accommodate different body sizes and are crafted from robust, enduring materials. 3. Toe boards: Positioned at the bottom of the formwork, toe boards prevent the dislodgement of tools, materials, or debris from the structure. Usually made of plywood or steel, these boards are firmly affixed to the formwork. 4. Safety nets: Installed beneath the formwork, safety nets are capable of catching falling objects or workers in the event of an accident. Comprised of sturdy, flexible materials, they possess the ability to absorb the impact of a fall. 5. Ladders and stairs: Employed to facilitate secure access to and from the formwork, ladders and stairs are typically constructed from steel or aluminum, ensuring stability and durability. 6. Warning signs and barricades: Warning signs and barricades operate as cautionary measures, alerting workers and visitors to potential hazards and restricted areas. These items are usually manufactured using durable materials and are brightly colored for enhanced visibility. 7. Personal protective equipment (PPE): PPE, including hard hats, safety glasses, and steel-toed boots, is a vital safety system employed in conjunction with steel formwork. These protective measures are designed to safeguard workers against head injuries, eye injuries, and foot injuries. It is important to acknowledge that the selection of specific safety systems for steel formwork may vary depending on project requirements and regulations. Construction companies and workers must meticulously adhere to all safety guidelines and regulations to establish a secure working environment.

- Q: What are the different types of reinforcement used in steel formwork systems?

- Steel formwork systems utilize various types of reinforcement to enhance the structural integrity and durability of concrete structures, each serving a specific purpose. 1. Rebars, also known as steel bars, are commonly employed in steel formwork systems to provide tensile strength to the concrete. These bars are positioned in the formwork prior to pouring the concrete, effectively preventing cracking and ensuring structural stability. 2. Wire mesh reinforcement, consisting of interconnected steel wires welded or woven together, is another frequently used type in steel formwork systems. Its purpose is to evenly distribute loads across the concrete, thereby improving its strength and reducing the risk of cracking. 3. Steel fibers, discrete reinforcing elements, are often incorporated directly into the concrete mix. These fibers enhance the concrete's tensile strength, making it more resistant to cracking and enhancing overall durability. Steel fibers are especially valuable in scenarios where traditional reinforcement methods may be challenging to implement. 4. Stirrups and ties, made of steel bars, are commonly employed in reinforced concrete structures and are also integrated into steel formwork systems. They secure the main reinforcement bars in place and provide additional support to the structure. Stirrups and ties prevent rebars from shifting or bending during concrete placement, ensuring proper alignment and spacing. 5. Steel plates and brackets are utilized in formwork systems to bolster support and stability. These elements are typically affixed to the formwork panels, acting as reinforcement mechanisms that distribute loads and prevent deformation or failure. Collectively, the various types of reinforcement used in steel formwork systems play a crucial role in guaranteeing the strength, stability, and longevity of concrete structures. They work in unison to withstand external forces, prevent cracking, and enhance overall structural performance.

- Q: How does steel formwork affect the overall constructability of the structure?

- Steel formwork can greatly enhance the constructability of a structure due to its strength, durability, and flexibility. It enables the construction process to be more efficient and precise, allowing for faster assembly and disassembly. The use of steel formwork also ensures consistent and high-quality concrete finishes, reducing the need for subsequent repairs or modifications. Additionally, steel formwork can be easily adapted to different shapes and sizes, enabling the construction of complex structures with ease. Overall, the use of steel formwork positively impacts the overall constructability of a structure by improving productivity, reducing construction time, and enhancing the final outcome.

- Q: What are the considerations when designing steel formwork for architectural sculptures?

- When it comes to designing steel formwork for architectural sculptures, there are several key factors that need to be taken into account. First and foremost, the structural integrity and stability of the formwork are of utmost importance. It must have the ability to withstand the weight of the concrete or other materials that will be poured into it, as well as any external forces that may be exerted during the construction process. This necessitates a meticulous analysis and engineering to guarantee that the formwork is sufficiently robust to support the weight and forces without any risk of collapse. Accuracy and precision are also crucial when it comes to the formwork. Architectural sculptures often demand intricate and detailed designs, so the formwork must have the capability to faithfully reproduce these shapes. This may involve the utilization of advanced computer-aided design (CAD) software to create precise 3D models of the sculpture, which can then be utilized to fabricate the formwork. Another important consideration is the ease of assembly and disassembly of the formwork. Architectural sculptures can be complex and intricate, thus the formwork must be designed in a manner that allows for effortless assembly and disassembly. This can involve the use of modular components that can be easily connected and disconnected, as well as the incorporation of features such as adjustable supports or brackets to accommodate different shapes and sizes. Furthermore, the choice of materials for the formwork is significant. Steel is a popular option due to its strength and durability, but depending on the specific requirements of the project, other materials such as aluminum or fiberglass may also be utilized. The materials employed must have the ability to withstand the weight and forces exerted during construction, as well as any potential exposure to weather or other environmental conditions. Lastly, the aesthetics of the formwork should be taken into consideration. While the primary function of the formwork is to support the construction process, it is also important that it does not detract from the overall visual impact of the sculpture. This can involve the use of smooth finishes, concealed connections, or other design techniques to ensure that the formwork remains visually appealing. In conclusion, the design of steel formwork for architectural sculptures requires careful consideration of factors such as structural integrity, accuracy, ease of assembly, material selection, and aesthetics. By addressing these considerations, designers can ensure that the formwork not only serves its functional and safe purpose but also enhances the overall artistic vision of the sculpture.

- Q: Can steel formwork be used for precast concrete slabs with openings?

- Precast concrete slabs with openings can indeed utilize steel formwork. Renowned for its durability and strength, steel formwork proves suitable for intricate and elaborate designs, including slabs with openings. By employing steel formwork, construction becomes precise and accurate, as it ensures the desired dimensions and shape of the openings. Furthermore, the steel formwork can be effortlessly adjusted and modified to accommodate various sizes and shapes of openings, granting design flexibility. In addition, the reusability of steel formwork renders it a cost-effective option for precast concrete slabs with openings. However, it remains crucial to engineer and design the steel formwork adequately to withstand the weight and forces exerted by the concrete and the openings.

- Q: What are the typical sizes and dimensions of steel formwork panels?

- Steel formwork panels come in a variety of sizes and dimensions, depending on the specific application and project requirements. However, the construction industry widely utilizes some common standard sizes. For wall formwork, steel panels typically have a height of about 2.4 meters and a width of 0.6 meters. These panels are available in different thicknesses ranging from 12mm to 18mm. They are designed to easily connect and stack together, forming a strong and stable wall formwork system. Slab formwork panels, on the other hand, tend to be larger. The standard size for these panels is approximately 1.2 meters in width, with the length varying according to the desired slab size. Like wall formwork panels, slab formwork panels are also offered in different thicknesses to support the weight and load requirements of the concrete slab. Apart from the standard sizes, customized steel formwork panels can be produced to meet specific project needs. These custom panels can be tailored with specific dimensions, shapes, and configurations to accommodate irregular or unique construction requirements. It's important to remember that while steel formwork panels offer strength and durability, they can be heavy and require suitable lifting and handling equipment for installation and removal. Moreover, it is crucial to follow proper safety measures when using steel formwork panels to ensure worker safety and project success.

- Q: Does steel formwork require any special tools for installation and removal?

- Typically, special tools are needed for both installation and removal of steel formwork. This is because steel formwork is heavy and rigid, which often means cranes, forklifts, or other lifting equipment are necessary to position the formwork panels. Additionally, tools like spanners, hammers, and wedges are commonly used to secure the formwork panels tightly and ensure stability during concrete pouring. When it comes to removal, power tools like grinders or cutting torches are usually required to disassemble and separate the formwork from the hardened concrete. These tools are needed to cut through any welds or bolts that hold the formwork in place. It is important to be cautious and follow safety protocols while using these tools. In summary, the heavy and sturdy nature of steel formwork necessitates the use of special tools and equipment for both installation and removal. This ensures that the formwork process is carried out efficiently and safely.

- Q: How does steel formwork affect the overall accuracy of concrete structures?

- The accuracy of concrete structures can be significantly improved through the use of steel formwork. By providing precise alignment and dimensional accuracy, steel formwork ensures a more uniform and accurate structure. To maintain the desired shape and dimensions of the concrete during pouring and curing, steel formwork offers a rigid and stable framework. This stability prevents any potential deformation or distortion, ensuring that the final structure adheres to its design specifications. Additionally, steel formwork contributes to a smoother surface finish of the concrete. The smoothness of the formwork surface reduces the likelihood of imperfections or irregularities in the final structure, ultimately enhancing its aesthetics and overall quality. Moreover, steel formwork allows for greater control and precision in the placement and positioning of reinforcement bars, which are crucial for the structural integrity of the concrete. Accurate placement of reinforcement bars guarantees proper embedding within the concrete, resulting in a stronger and more durable structure. Furthermore, the high level of reusability provided by steel formwork further enhances accuracy. Its durability allows for multiple uses, minimizing the risk of wear and tear that could affect the formwork's alignment and accuracy. In conclusion, steel formwork plays a vital role in ensuring the overall accuracy of concrete structures. It provides stability, precise alignment, smooth formwork surfaces, and reusability, all of which contribute to a more accurate and aesthetically pleasing final product.

Send your message to us

Heavy Duty Whole Steel Formwork for Bridge Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords