High Quality Rigid Polymer Fiber

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Instructions of High Quality Rigid Polymer Fiber:

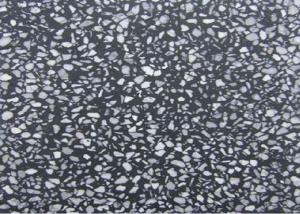

The High Quality Rigid Polymer Fiber uses polypropylene as its raw material. It is a substitute for steel fiber in the reinforcement of cement concrete and crack resistant. Compared with steel fiber, it has the advantage of easy dispersing and blending, no damage to the mixing equipments, high break strength, strong bondability, etc.

Technical Data of High Quality Rigid Polymer Fiber:

Equivalent Dia(mm): Ø 0.3±0.05

Strand Length(mm): 20,30,54

Density(g/cm 3 ): 0.91

Elastic Modulus (MPa): >3500

Shape: bundle-like and twisted

Tensile strength(%): 8-15

Break Strength(MPa): ≥ 350

Resistance to acid,alkali: strong

Features of High Quality Rigid Polymer Fiber:

1. Ration design of the fiber concrete

The recommended volume for concrete is more than 2.7kg /m 3 ( volume ratio is 0.3% ) , reinforcement adding amount is 5.5kg , Compared with adding 47kg of steel fiber, 5.4kg polymer fiber has the same volume ratio to the concrete.

2. length

50mm for common crack-resistant requirement.

3. Matching Ratio

Usually, it is no need to change the matching ratio of the concrete.

Considering the requirement of fissure-resistant, the polymer fiber is recommend to combine with the polypropylene fiber mesh with the volume ratio of 1:1( 0.9kg fiber-mesh to per sqm of cement concrete).

4. Mixer Adoption

Double-axle horizontal compelling mixer is priority.

5. Mixing process

Crushed stones, fibers and sands are put into the mixer in succession. After stirring for two minutes, fiber will fully disperse and then add cement, water and stir normally. The addition materials also can be put into as common concrete, but the stirring time should be properly prolonged to make fiber completed mixed.

- Q: i needed regrouting done on the paved edges of my swimming pool, the guy i hired done the job but he didn't clean the pavers afterwards properly so now there's a very slight film of cement grouting washed over the pavers - it makes them look slightly powdery. He said it would wash away but since then there's been heavy rain a few times but it still hasn't come off. What do you suggest i do to remove that residue? I thought about hydrochloric acid but I was worried it might damage the natural sheen in the pavers? what do you think...............

- For removing a light haze try regular vinegar. It is a mild acid and works well in this application. I use a plastic spray bottle and a medium bristle brush. Spray an area and scrub with brush rinse with clear water. May take a couple applications.

- Q: Its said that Hindus Muslims cant coexist .Sikhism has common points from both Hinduism Islam .Absolute Hinduism Islam would find it difficult as they are apart poles each other .Have Sikhs saved Indian nation integration by acting as buffers ??

- You are right to say Sikhism is a fusion of Hinduism and Islam but, no, I think Muslims and Hindus can co-exist despite their religious differences. Muslims and Hindus are intelligent people and are capable of respecting each other, well execpt for a handful of religious extremists on both sides.

- Q: if i have a footing 22ft long by 18inches deep by 10inches wide how many yards do i need

- 27 1/2 divided by 1760. Abhijit.

- Q: what is sound proof cement made out of?

- Cement isn't really sound proof. If someone said something like I was trapped in a sound proof cement chamber It means that the chamber was sound proof, not the cement it self.

- Q: RE cement-based polystyrene particles outside the wall insulation system and powder polystyrene particles external wall insulation system materials What is the difference

- However, RE cement-based polystyrene particles external wall insulation system is only the above concept (powder polystyrene particles external wall insulation system) in a member, especially the use of "RE cement-based polystyrene insulation mortar" made of this material Wall insulation system

- Q: Is dry cement powder dangerous.?

- breathing in any powder is dangerous...i have been breathing it in for 37 years now and stand a good chance of getting silicosis which is what you get from breathing it...but i try to wear a mask whenever possible...chances are i wont get it...

- Q: we are interesting in using larger travertine tile

- most tile is put down on cement so your alright there. go to your hardware store and thy will fix you up but you need a mortar that is good for out side like what you would use for a shower don't for get to put a sealer on it or all your hard work will be for nothing

- Q: What are the advantages of the cement house over a more traditional wooden house and how did this preference for cement come about?

- Cement houses are much cheaper. But I live on 50 yrs old wooden house and ventilation is an advantage, also have ancestral wooden house in Quezon Province, lot of trees.

- Q: In the experiment of analysis of cement in labs, cement contains more chemical elements. now I like to estimate the amount of silica in cement. how?

- well the answer is very simple........... you know i suppose that NaOH reacts with silica to give sodium silicate? and sodium silicate is basic in nature/....... so just take a sample of cement make a solution of it.... or maybe a suspension , weigh it and start adding NaOH until the indicator (phenolphthalein) changes colour..... the reaction is...... NaOH+SiO2---------->NaSiO3+H2O just balance the reaction and there you have your answer...........

- Q: What is the wood template and the iron template? Where can I buy? There are triangular iron. The More

- A large number of sale of old wooden template, wooden side you. Large favorably. The contact method is my username

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Rigid Polymer Fiber

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000 Kgs kg

- Supply Capability:

- 100000 Tons Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords