Acrylate Rubber Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees..

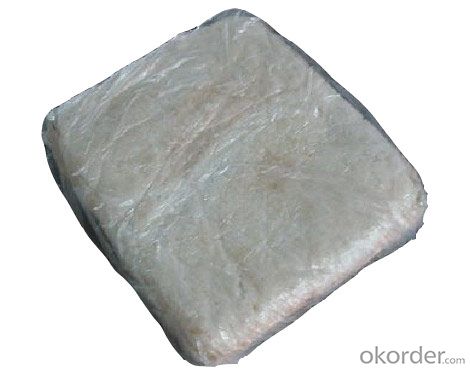

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the difference between TPE material and silicone rubber?

- Silicone rubber is a kind of special rubber, cross-linking has good mechanical strength, wear resistance and high temperature resistance, which belongs to the thermoset rubber, vulcanized after heating when the temperature is too high will not melt, combustion, complete combustion product is water and silica

- Q: Oak, Manchurian ash, ash wood, pine wood, rubber wood material which is best? What are the characteristics?

- Then walnut, hickory, walnut and lumber are also availableRubber wood is not oak, oak is North American rubber, wood is Southeast Asia, the price is 3-4 times worse. The texture is different

- Q: Do the rubber mold steel mold and what material good, now with Luo No. 12 steel sticking seriously?

- Adding rubber powder release agent in the formulation, proportion of 0.6-0.9%, the price of only a few thousand dollars a ton. The utility model can effectively solve the difficult problem of demoulding of rubber products.

- Q: What's the difference between sole material MD and TPR?

- TR:TPE and rubber synthetic material, with the appearance of many patterns, feel good, bright color, high smoothness, high technical content, and can be recycled 100%, belongs to environmental protection type sole material.

- Q: What material is the line on the rubber court floor? What's the practice?

- According to the leveling layer thickness and rubber flooring laying time plan, as early as possible leveling layer construction, in order to ensure dry.In order to ensure the effect of large area (flatness). Strength) it is necessary to use bottom oil and self leveling on leveling layer before laying.In order to ensure the laying site has enough strength to set off on the structure of each layer, and under high load in the future, that should choose high grade leveling layer, such as fine stone concrete practice, it is recommended that the mark of C30.In China, people are accustomed to using PVC resin as raw material for the production of the floor PVC sports flooring (referred to as artificial leather); using PU resin as raw materials for the production of artificial leather called PU artificial leather (PU leather) with PU resin and non-woven synthetic leather as raw material called PU floor (referred to as synthetic leather). The difference between PVC and PU sports flooring flooring can be used synthetic gasoline difference method is with a small piece of fabric, put in gasoline for half an hour, and then take out, if it is PVC sports flooring, is hard and brittle, if PU synthetic leather is not hard and brittle. PVC floor construction plan

- Q: What is the raw material of artificial natural rubber?

- Tapioca, American rubber, India fig, African cane gum and Brazil trefoil rubber. But it has the advantages of high yield, good quality, long gum production period, low cost of making rubber and convenient processing. It is only one kind of Brazil trefoil rubber. Its yield has accounted for more than 99% of the total output of natural rubber. Made from synthetic rubber.

- Q: Hello! Our factory produces PVC toy balls with PVC resin powder and two pungent fat. Would you like to add fine rubber powder in the raw material?

- The addition of fine rubber powder will make the PVC toy ball have certain tenacity and elasticity, and it is difficult to add too much. It is recommended to add (liquid nitrile or nitrile powder), it is not recommended to add recycled rubber powder!! The proportion is usually about 5% of the mass!

- Q: What kind of materials do rubber and leather paint belong to?

- Rubber paint is widely used in ABS, PVC, PC, PS, and other material and hardware, plastic products, metal spraying special primer, bakelite, wood, ceramics and other products. Spray the product has special soft, smooth, delicate, sensual touch and a rubber like texture and skin feeling, give a person a kind of very happy and feel comfortable. Decorative products to make the effect more noble and elegant, clean and generous, and more show the value of the product.

- Q: What are the advantages and disadvantages of plastic, nylon, and rubber materials commonly used in spectacle frames?

- Rubber often refers to in life is the synthetic rubber. Such as Dow Corning produced TPSIV material.Nylon advantages: the price is cheaper than rubber (20-30 yuan per kilogram), hard texture, high fatigue strength and steel, better heat resistance, low coefficient of friction, good wear resistance.Rubber (TPSIV) advantages: feel silky, antibacterial ability prominent, in the thermal elastomer, wear-resistant excellent, in daily life is extremely resistant to corrosion, UV resistance, coating material wide, without ash, heat resistance good.Nylon defects: feel, hard texture, moisture absorption, dimensional stability is not enough.Rubber defects: high cost. The average price is 120-150 yuan per kilogram.

- Q: Colorful cars are mainly made of plastic, rubber and other materials?

- Plastic and rubber are high molecular material, mainly composed of two kinds of carbon and hydrogen atoms, and some contain a small amount of oxygen, nitrogen, chlorine, fluorine, silicon, sulfur atoms, its special properties, use is also special. At room temperature, the plastic is not solid, hard, and tensile deformation of rubber hardness is not high., elastic, can be stretched, and stop pulling back to normal. This is due to differences in their molecular structure. Another difference is the plastic can be repeatedly recycled, while the rubber cannot be directly recycled, can only be processed and then reclaimed rubber, plastic and rubber. Available in the form of more than 100 to 200 degrees at 60 to 100 degrees. The morphological similarity does not include plastic rubber.

Send your message to us

Acrylate Rubber Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches