The Middle Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

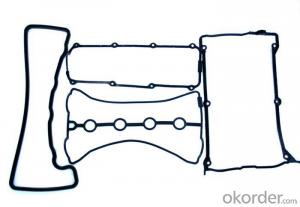

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Does the 2009 SR Suntour Rux have 20mm Thru Axle? Also for this fork 2008 Sr Suntour SF7 XCM?

- no they do not they have a leading axle design Suntours 20mm thru axles have 20 in their name for example SF8-DURO FR20 SF9-DUROLUX 20 TS SF9-DUROLUX 20 1.5 are all 20mm through axle designs not sure the actual measurement of a lead axle design but if your looking for a 20mm the sf7 scm is not the one for you.

- Q: I am going to build a trailer out these. There are three axles all together.

- There should be a small plate mounted near the towing hitch showing the total weight the chassis and axles (as one unit) can carry. As this plate is a legal requirement in the UK, I should have thought you would find one on any caravan your're pulling to bits.

- Q: I am trying to build a mousetrap car for my physics class and i don‘t know what to use as a hook to grab my string on my rear axle for my mousetrap car. Please suggest something reasonable.

- This is a car that is powered by a mousetrap? Maybe you could try what those old caged gyroscope toys and some tops used to use. Drill a hole through the axle, and put your string through it. Wrap the string around the axle a few times. When you yank on the string, you spin the axle until the string comes loose. I don't know if a mousetrap would provide enough torque for this to work, and you'd have to make sure your string was JUST short enough to ensure that it comes out, or else it'll just get wrapped around the axle again, stopping your car.

- Q: Just wondering

- Not ALL do. But for the most part, it is for the weight factor. Not all that have two rear axles are both drivers. Some have one driver and the other is referred to as a TAG (tag along) axle.

- Q: what is a trans axle fuse purpose?

- Really, you're blanketing him depends entirely on whether he grows a sufficient winter coat or not. If he grows a nice coat, he'll probably be fine with the medium on only the coldest days (20). If he does not grow a good coat, you'll probably need to get a heavy weight. good luck :)

- Q: I am building a Rube Goldberg device and i need to find a way to make a lever go from pointing up to the right, to pointing down to the right. Can i do it by cranking a wheel and axle? If not, are there any other ways to do it?

- if you mounted the axle at a right angle to the lever and put another wheel on it with a dowel mounted to the rim(making a cam of sorts) that extends under the lever you could turn the handle wheel causing the cam to rotate under the lever ,raising or lowering the lever at need.By changing the position of the axle in relation to the pivot of the lever and changing the cam size you can get any amount of movement you need.Also by increasing the number of dowels on the rim you would increase the amount of time(or degrees of rotation) that the lever is elevated,if you wanted the lever to go up and down with every rotation of the hand wheel or you could put stops on the handwheel to lock it in the position you want(lever up or down) Well good luck ,it sounds fun

- Q: i have a 1986 ford bronco and i was wondering how to replace the axle pivot bushings and how many there is to replace

- Their are 2 axle piviot bushings, and they are not very easy to replace. I normally use a porto-power and chain hoist. You use the chain hoist to keep the axle from spreading apart to much and the porto-power to ease the axle down and back up after replacing the bushing. Normal labor for each is about a hour for a shop. Good Luck!!

- Q: i need to replace axle assembly on 1999 isuzu trooper

- rear axles undo 1. tires and drums 2. the 4 big bolts in back of brake assy. 3. get a slide hammer, install on the lug nuts. and hammer away. good luck getting the bearing out, to replace the seal.

- Q: I have a 1965 Toyota FJ40, and I was wondering if there was any way to change the stock front axle 6 lug pattern to and 8 lug pattern. I need to do this to match the 8 lug i have in back(its a Dana 60), and i dont want to have to buy a whole new axle if i dont have to. So is there any way to do this?Thanks, I appreciate all the helpand be expecting to see some more questions I have about the FJ40s lol.

- no kind of drive will save you on ice. fwd, rwd, awd and even 4x4s. like the guy said above, in snow fwd would be better becuause you go wherever you point your tires. mud is probably the same. but awd is the best of both worlds. front wheels pulling and rear wheels pushing.

- Q: What are the factory axles for a 1991 Jeep Cherokee.?

- The axles are an internal component of the differential. The axles are what transfers (connects) power from the 3rd member to the wheel. They ride on bearings.

Send your message to us

The Middle Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches