Aluminum Tread Plate Thickness

Aluminum Tread Plate Thickness Related Searches

Aluminum Plate Thicknesses Thickness Of Aluminum Plate Aluminum Skid Plate Thickness Aluminum Tread Plate Weight Tread Plate Aluminum Aluminum Diamond Plate Thickness Tread Aluminum Plate Aluminum Plate Thickness Chart Aluminum Tread Plate Patterns Polished Aluminum Tread Plate Aluminum Tread Plate Prices Aluminum Tread Plate Sheet Diamond Tread Plate Aluminum Black Aluminum Tread Plate Aluminum Tread Plate Sheets Density Of Aluminum Plate Aluminum Diamond Tread Plate Tread Plate Aluminum Sheets Aluminum Tread Plate For Trailer 4x8 Aluminum Tread Plate Aluminum Tread Plate Sheet Metal 4017 Aluminum Tread Plate Aluminum Tread Plate 4x8 Diamond Tread Aluminum Plate Aluminum Tread Plate For Sale Aluminum Plate 1 Inch Thick 3003 Aluminum Tread Plate Aluminum Tread Plate Suppliers Aluminum Plate Tolerances Aluminum Stock ThicknessAluminum Tread Plate Thickness Supplier & Manufacturer from China

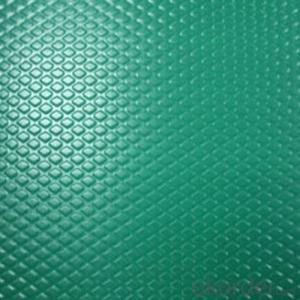

Aluminum Tread Plate Thickness is a type of aluminum sheet material that features a raised diamond pattern on one side, providing excellent slip resistance and durability. This product is manufactured with varying thicknesses to cater to different requirements and applications. It is known for its lightweight properties, corrosion resistance, and ease of maintenance, making it a popular choice in various industries.The aluminum tread plate thickness is widely used in a range of applications, including flooring, stair treads, walkways, and platforms. It is particularly suitable for environments where slip resistance is crucial, such as commercial kitchens, industrial facilities, and marine applications. Additionally, its aesthetic appeal makes it a popular choice for decorative purposes, such as in retail stores and public spaces. The diamond pattern not only enhances safety but also adds a modern and sleek look to the surface it covers.

Okorder.com is a leading wholesale supplier of aluminum tread plate thickness, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum tread plate thickness they provide meets the highest standards. Their extensive inventory allows customers to find the right thickness and size for their specific requirements, making it a one-stop solution for all aluminum tread plate needs.

Hot Products