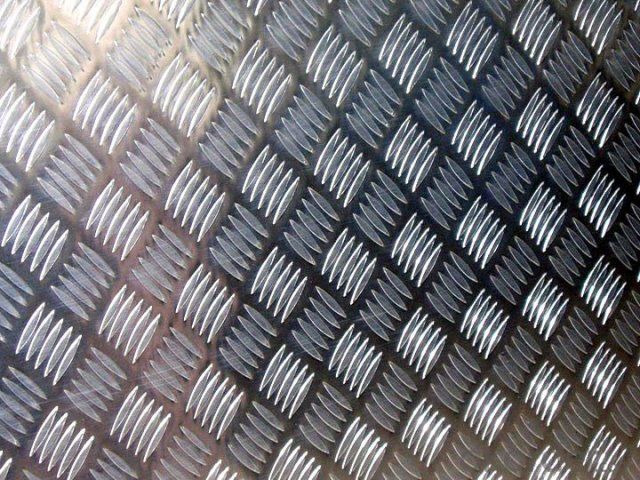

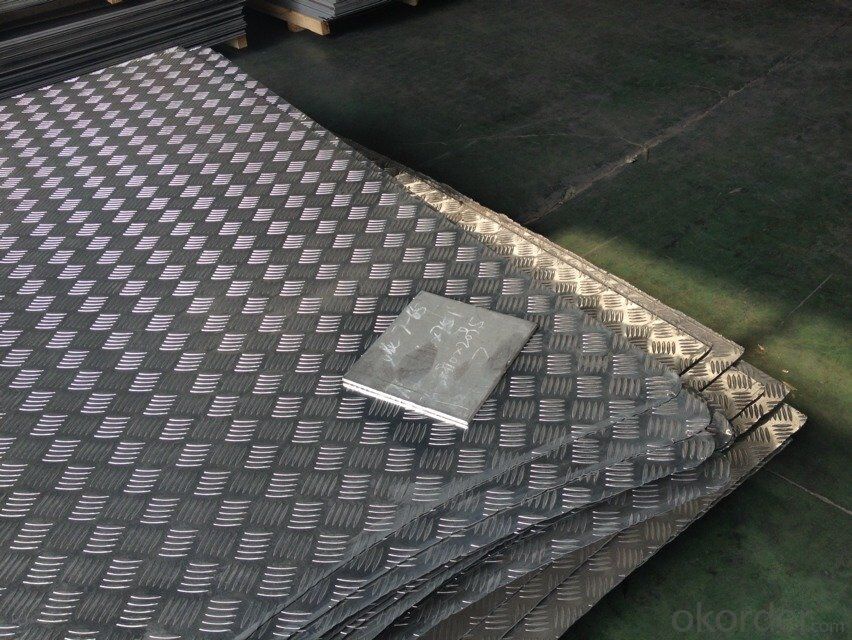

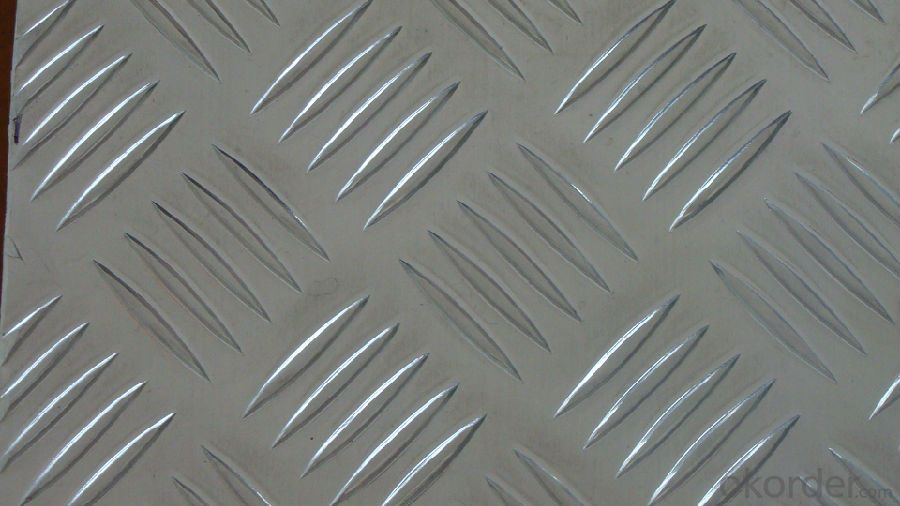

3003 Aluminum Tread Plate, Aluminum Anti Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

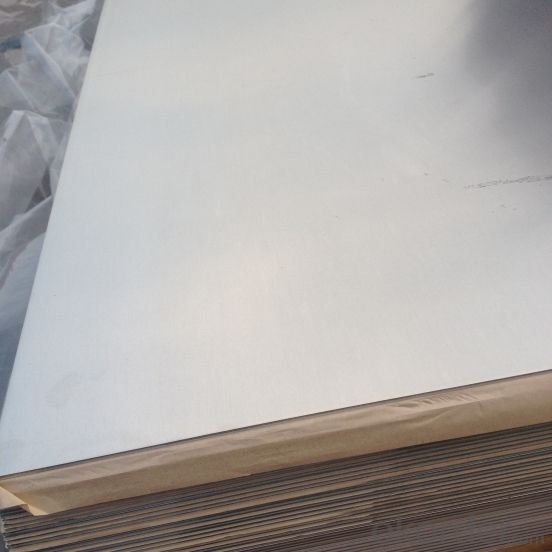

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Are aluminum sheets suitable for aerospace engine components?

- Aerospace engine components can indeed be made from aluminum sheets. Aluminum is widely employed in the aerospace industry because of its advantageous properties. Its lightweight nature is crucial for aircraft and spacecraft applications, as it aids in reducing overall weight and fuel consumption. Furthermore, aluminum possesses outstanding thermal conductivity, enabling efficient heat dissipation generated by the engine. This characteristic is essential for maintaining optimal operating temperatures. Additionally, aluminum exhibits a commendable strength-to-weight ratio, corrosion resistance, and ease of fabrication. These qualities make it suitable for various engine components like casings, housings, and structural elements. Nevertheless, it is important to note that not all engine components can be solely constructed using aluminum sheets. Certain parts may require higher strength materials or specific alloys to withstand extreme temperatures or stresses. Overall, aluminum sheets have proven to be a reliable and frequently employed material for aerospace engine components. They significantly contribute to the overall performance and efficiency of aerospace engines.

- Q: write a balanced equation for the reaction between aluminium metal and potassium hydroxide in water

- So convert 27,8 g iron to moles, and convert that to a mass of aluminium 2. 3 CuNO3 + Fe3+ -- Fe(NO3)3 + 3 Cu+ 3. 2 Fe3+ + 3 O2- --- Fe2O3 So convert Fe2O3 from 20,8 grams to moles. Multiply this answer by two. Convert to a mass of Fe3+ 4. H2SO4 + 2 KOH -- K2SO4 + 2 H2O again, 150 grams of H2SO4 to moles, then convert that amount to an amount of mass of K2SO4 5. Na2CO3 + 2 H3O+ + Cl- --- CO2 + 3 H2O + NaCl

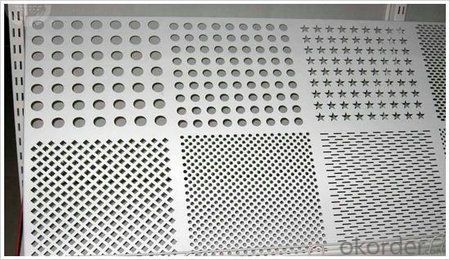

- Q: This question asks about the various colors and finishes that can be applied to aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors and finishes, offering versatility for various applications. Common colors include silver, white, black, and bronze, but they can also be anodized or painted to achieve virtually any color. Finishes can be smooth, brushed, or embossed, with options like matte, satin, and gloss. Additionally, there are specialty finishes like mirror-like polished, hammered, and wood grain textures. The choice of color and finish depends on the specific requirements of the project, such as aesthetics, durability, and resistance to environmental factors.</p>

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- Aluminum rusts just like Iron, but Aluminum Oxide (unlike Iron Oxide) is tough and forms a layer a molecule or (a few) two thick and does NOT flake off easily. A related form you'd be familiar with is Corundum (2 Aluminum molecules and 3 Oxygen molecules + some trace elements), aka sapphire or ruby depending on being blue or red respectively. This is the same material that Rolex uses to make its watch faces; the famous sapphire surface that is highly resistant to scratching. In short, you have nothing to worry about, especially as aluminum used for commercial purposes is often alloyed with Chromium to increase durability.

- Q: Can the aluminum sheets be used for manufacturing electrical connectors?

- Yes, aluminum sheets can be used for manufacturing electrical connectors. Aluminum is a lightweight and highly conductive metal, making it suitable for transferring electricity. It is often used in various electrical applications, including connectors, due to its excellent conductivity and corrosion resistance. Additionally, aluminum can be easily shaped and formed into different connector designs, making it a versatile material for manufacturing electrical connectors.

- Q: A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Densities: Aluminum: 2,710 kg/m^3 Copper: 8,940 kg/m^3 Basis: 1 m^3 of copper-aluminum alloy mass of aluminum in 1 m^3 alloy = 519 kg vol. of aluminum in the 1 m^3 alloy = 519 kg/(2710 kg/m^3) = 0.1915 m^3 vol. of copper in 1 m^3 alloy = 1 m^3 - 0.1915 m^3 = 0.8085 m^3 mass of copper in 1 m^3 alloy = (0.8085 m^3)*(8,940 kg/m^3) = 7,227.87 kg mass of the m^3 alloy = 7,227.87 kg + 519 kg = 7,746.87 kg %weight of aluminum = (519 kg/7,746.87 kg)*100% = 6.70% The alloy has 6.70% by weight of aluminum in it.

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Yes, aluminum sheets are suitable for use in marine or saltwater environments. Aluminum has excellent corrosion resistance properties, making it a popular choice for marine applications. It forms a protective oxide layer that prevents further corrosion, making it durable and long-lasting in saltwater environments.

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- Connections at ceiling lights have far less potential for a problem, but a potential none the less. So, while you are at it, go ahead and check them. The antioxidant compound and al/cu listed wire nuts (marriets) are the correct and proper materials to use. I applaud you for having done your homework. After tightening each connector be sure to pull on each and every wire to ensure they are good and tight. When combining solid and stranded wire, slide the stranded past the solid about an 1/8 before capping. We in the trade use 9 lineman's pliers to twist all wires before capping them. An inexpensive pair (of Lineman's) can be had for under $20. A good pair of wire strippers (with built in screw cutters) can be had for about $15. I mention the screw cutter because there is a good chance that somewhere along the line you will find a location where the stock 7/8-1 screw bottoms out against something before it gets tight. If you force it it will strip out. Not to mention it might dig into the insulation on a wire resulting in a short. Screws in devices (receptacles, switches, dimmers etc.) are 6-32 and light fixtures are typically 8-32. I would also get a non-contact tester. A.k.a. inductive tester. Very handy at times. When you are sure the power is off to a box it might not be. On an occasion another hot will be present. The beep testers will quickly alert you to the presence of another live circuit. A multi-tester will allow you to identify wires should you fail to mark them before working on them. If you mark the location of each wire to a 3 or 4-way switch before replacing it you will save yourself a lot of time. Same with wires to any GFI receptacles. Swapping wires location to location may not be correct. Some have the Line terminals on one side, while most have them on the top. But I get the impression you have a bit of experience or a friend who does helping you with this.

- Q: why is copper sheet but not aluminum sheet that becomes the negative pole after putting copper sheet and aluminum sheet connected with wire into concentrated nitric acid?

- According to metal reactivity series order table, aluminum has a better metallicity, but it will be passivated soon after contacting concentrated sulfuric acid, and won’t react again. But copper and concentrated sulfuric acid can react continually. So aluminum sheet becomes the positive pole after passivation.

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

3003 Aluminum Tread Plate, Aluminum Anti Slip Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords