Fiber Cement Boards For Interior Wall Partition/Interior Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

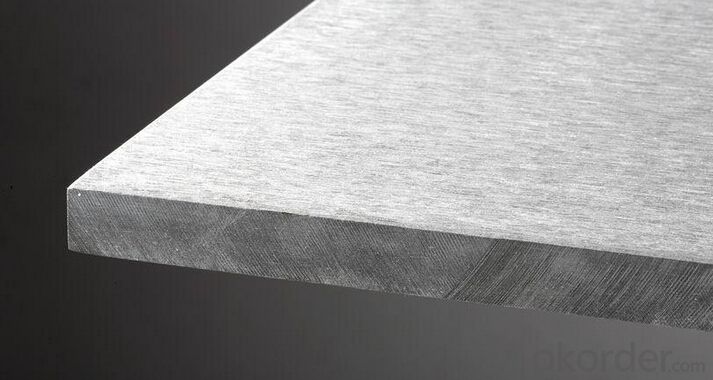

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my jumping around on it.

- This Site Might Help You. RE: is there a cinderblock or cement anchor that will hold lots of weight? 200 lbs plus? I am trying to anchor a woody climbing wall to a cinder block garage wall and have settled on anchoring boards into the cinder blocks then building from there. so anything anchored there would be sharing a load of me-200 lbs, the plywood base and frame - 50lbs. plus any force generated by my...

- Q: Do not you dry the stone

- Yes, as long as the cement surface to ensure the smoothness of the surface roughness and verticality can be directly sprayed.

- Q: Hi, I have an outside breezeway that connects from my house to my garage with a roof and cement slab. I'm in the process of closing it in and making it part of my house(fully heated). I'm going to tile the floor but I'm not going to have a sub floor to insulate under it, I worry about moisture, cold floor and cracking of tiles (I live in Michigan).So my question is I'm not sure on how to go about this, I was thinking a 1/4 to 3/8 insulation rolled on the slab, then cement board and then thermostat controlled heating mat then tile, What do you think, thanks.

- I agree with William, use a rigid insulation rather than a roll insulation. It would be pretty much impervious to moisture. A roll insulation would eventually hold any moisture and get moldy and lose any r-value.

- Q: Can cement pressure plates be used for external walls? Oblique wall, can play a waterproof role? Durable?

- This is not waterproof ah! Like this wall must first do waterproof.

- Q: Fiber cement board and the difference between the water board

- Water board, also known as decorative concrete, is a water concrete slab. Different from ordinary concrete, it is smooth surface, uniform color, angular, no damage and pollution, but in the surface coated with a layer or two transparent protective agent, it is very natural, solemn.

- Q: On the difference between the cement pressure plate, the fiber cement board, the Etter board

- Steamed into a new type of building plate. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Mainly used for internal and external walls, pouring walls, composite panel wall panels, fire door lining, external wall insulation panels. ? Ette board is a fiber reinforced silicate plate (fiber cement board), the main raw material is cement, selected minerals, by the high temperature autoclaved autoclaved, waterproof performance, can be used as toilet Wall, or outdoor roof roof, or external wall with the board can be in the long-term damp environment to maintain stable performance unchanged.

- Q: I know cement board to cement board is taped with thinset and fibatape, but what about the seam at the sides that meet drywall? How should these be taped. What Materials should be used?

- You can use the fiberglass tape. Just apply compound on the drywall half and thin set on the cement board side.

- Q: do i need to put down cement board on concrete before laying tile?

- no just clean and smooth the floor see flash patch .

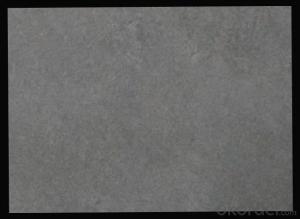

- Q: Want to do their own cement board, but made out of the color on the white, how can make the cement board color made dark gray

- I suggest you use PC32.5 cement (composite cement), because the cement is mixed with a lot of fly ash so this kind of cement to do the surface color is the deepest, of course, some of the factory with the lighter gray color, then After the cement is condensed, it is also darker than other cement, and some fly ash is grayed out. You buy cement when they look, there is a way to mix cement when they add coal dry stone powder or fly ash, of course, the strength of cement down, so if the choice of the latter should be mixed with their own purchase PO42.5 grade cement to blending, or do out of the cement board strength is too low is not enough. If the composite cement and then mixed with the need to grasp the amount of the problem.

- Q: Is the cement fiber outer wall plate affected by the blisters?

- In particular, the water absorption of the sheet is very important, especially asbestos-free, the density is inversely proportional to the water absorption, the higher the water absorption, the lower the density, the resistance to freezing and thawing and stability The worse, the easier it is to stratify,

Send your message to us

Fiber Cement Boards For Interior Wall Partition/Interior Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords