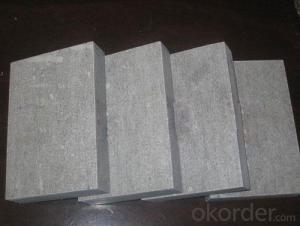

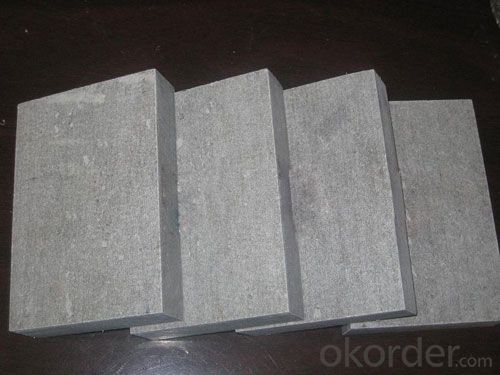

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Which port do you choose for FOB ?

Answer: FOB Shanghai Port.

2. What's your delivery time of your products?

Answer: About 20 days after confirm the order.

3. What about the terms of payment?

Answer: 30%TT advanced payment, balance seven days before shipment.

Other terms of payments also can be negotiated.

4. What's your Minimum order quantity(MOQ) of your product?

Answer: Generally, MOQ is 1x20' container. Others can contact with me directly.

Images:

- Q: Yesterday I started a job at a warehouse store. This store, being a warehouse has cement floors. I have a pair of walking shoes I wear with added inserts for more comfort, but after my shift yesterday, I could barely walk because of the pain in my hips, knees, foot/leg joint, and my ankles. I know that arthritis runs in my family, and that other family members have had problems when dealing with cement floors. I'm only 23, but I know arthritis can start that young (I also know my knees are total crap because of sports). So my question is, could this pain be from walking on the cement floors all day, or is this just random? I never had this happen this bad before, and have never had to be on cement floors that long either.

- Hi there: I know this the floors will just kill my feet when working on cement. You have a fine day..

- Q: What are the prospects for the development of wood fiber cement board?

- VIVA wood cement board products; won the 2003 outstanding product Jin Ju Award for a modern, high-quality, economical and economical new building materials, the special surface lines can highlight the high value of texture and unique taste.

- Q: Seeking wire mesh clip on both sides of the foam cement mortar to do the wall technology.

- First fixed a good frame, and then fixed with a wooden keel wire mesh plus foam. If you are afraid of overweight, to switch to wood plaster gray knife.

- Q: Cement board can not wet paste

- Cement board is to wet paste.

- Q: Cement board to do the bathroom top off the skin, how to deal with

- Cement board is not suitable for ceiling materials, it is easy to crack, a thorough way is to remove, re-integrated ceiling or waterproof gypsum board ceiling.

- Q: How to do the basement of the cement board

- Cement board can not be done directly on the basement membrane, should first put the putty to make the wall flat, and then paste the wallpaper the day before the brush base film, just wiped the concrete wall, can not scratch the putty. Because the water has not been completely dry, put on putty powder will cause cracking.

- Q: some say lay 15 pound paper what gives?

- It's a cushion -bed for the cement board. Less chance of it cracking if cushioned.

- Q: Fiber cement board and the difference between the water board

- Wooden cement board construction / Miyan cement board characteristics Wood fiber cement board price / US rock cement board price / Yongfeng International Beijing Guangda Sunny Trading Company has always been adhering to the concept of innovation and promotion of architectural style advocates in the domestic market to lead Trend, the latest foreign environmental protection building decoration materials into the country, the gray style to the climax of gray.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q: I need to have my foundation parged with waterprof cement. the area is about 350 sq ft. How much should I expect in materials and labor? i live in new england area.

- I own a waterproofing company in the Nashville area. The membrane with protection board is $1.50 per. sq. ft. here. I would recommend a rubberized product instead of cement.

Send your message to us

Fiber Cement Boards For Interior Wall Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords