Fiber Cement Board for Modular Wall Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

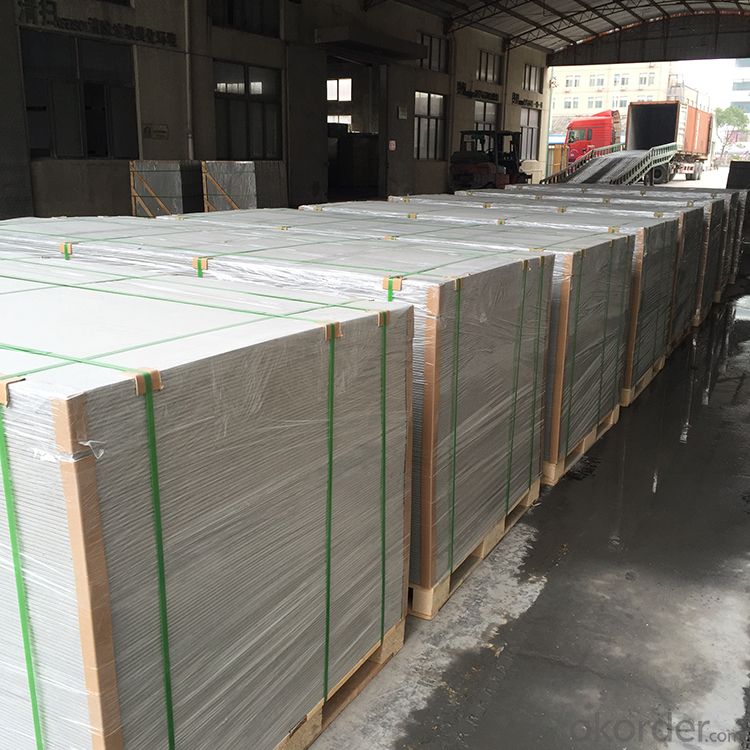

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Fiber cement board is a new architechural and industrial board with cement, quartz, matural and selected minerals as main materials. The board was made through high temperature and high precessure maintenance and other special treatments. It is the first choice for lasting building materials in some developed countries as well as being increasingly applied in more countries.

Specifications

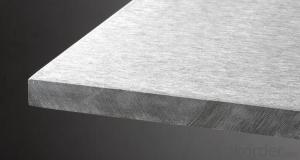

1220x2440x4-20mm, Max width: 1220mm, Max length: 3000mm

Other optional specification available

Optional sanding finishing on the surface

Advantages

1. 100% Asbestos Free

2. Fire Resistance

3. Earthquake Resistance

4. High Strength and Good Stability

5. Inorganic Material and Anti Fungus

6. Good Heat and Sound Insulation

7. Durability and Long Service Life

Typical Applications

Commercial mansion, Industrial building, Hotel, Hospital, Theater, Station, Factory, Warehouse, etc.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Picture

- Q: Wooden cement board and cement pressure plate is the same thing?

- Wooden cement board is a non-toxic building material board that does not contain any volatile toxic substances such as asbestos and formaldehyde. Wood fiber cement board will not produce any harmful substances, excellent environmental performance. Wooden cement board contains 71% Portland cement, 19% mineralized wood fiber, 9% moisture and 1% binder. Wood fiber cement board in line with ASTME 136 non-flammable building materials standards, structural performance. Soaked in water without stratification, uniform set evenly. Wooden cement board can be cut, planing, grinding, drilling, threading, and can be fixed with nails and screws.

- Q: Lightweight composite wallboard can not be attached to the wall

- Light, economical, cost-effective. Infrastructure design began to use lightweight partition, can greatly reduce the structure and the basis of cost, and optimize the beam and column structure, the overall layout of the room more reasonable, more use of the function. Increase the use of area, improve the construction period. Economic benefits are more superior. After the use of lightweight composite wall panels, the weight of the building is reduced, the cross-section of the component is reduced, the seismic force is reduced, so that the overall force has improved, the internal force of the beam and the column is reduced accordingly, so the reinforcement is also reduced , And reduced the structural cost.

- Q: I want to remove and replace my laminate covered counter tops, the particle board underneath is chipping bad near some edges,and there's almost no good place to put screws in to hold the dishwasher. I need plans or instructions how to build a replacement so I can use plywood and cement board to install ceramic tiles. How do I frame it for the sink and the edges?

- Actually you don't really frame a sink. You can add blocking underneath to screw to, but you really just cut the sink hole, if you are using the same sink then you will need to use the old hole as a template for the new one. If you are putting in a new sink then you will use the template on the box. You should use at least 3/4 high grade plywood and add the tile backer boards to the top. That will make it plenty think. You just cut the boards the size of the old countertop and screw then to the blocking on the wall and to the blocking in the cabinets. Blocking is additional pieces of wood that are strategiacally placed to have a larger surface to screw into and additional support. I am in commercial construction and we place the blocking inside the walls before we sheetrock, but in your case you may have to add it in other places to have enough support. Hope you have lots of luck, take your time and if you start to get frustrated ask for more help.

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- External walls are generally used to deal with putty, specifically including the following steps (the above content are from the general source of paint official website related information):

- Q: How to do the basement of the cement board

- Base treatment: cast-in-place concrete wall, due to floor, materials, release agents and other reasons, the wall flatness is poor, often stomata, honeycomb, Ma, yin and yang angle and drums and other phenomena, Department of ticking flat, concave to fill the fill. For the prefabricated concrete floor, slab base, must be hand brush with a wire again, the surface of floating sand, pimple, dust and other debris removed clean. For the cement mortar paper layer of gray surface requirements of the surface layer of dry, solid clean (no floating oil) can be.

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- There are water block paints and such... but the cost would be too exorbitant for what you need to accomplish. ALSO.. most laminate floor manufacturers state that a 6 mil plastic sheet vapor barrier is what they require, when installing their products on concrete. (This goes on the concrete, then the foam underpad goes over the plastic sheeting) You can buy 6 mil plastic by the roll.... 10ft x 25ft, or longer.. in clear or black, and isnt that expensive. It's what the manufacturers suggest, I'd stick with it, or you're going to void your flooring warranty.

- Q: How the cement pressure plate sticks on the brick

- Base treatment: the dust, debris thoroughly cleaned, no hollowing, cracking and sand and other defects. Pin line: before the construction of the wall around the height of the pop-up control line, in the ground pop-up cross-line to control the floor tile size.

- Q: How durable and lasting is the concrete board that is installed on homes? IS it true that it doesn;t need painted for at least 15 years?Thank you

- it can last even longer depending on exposer to weather, feild painted or factory painted. hardi plank or certinteed cement board are both good products. the main thing is to keep the back side of the board ( keep n eye on your caullking ) if moisture can wick threw the board , the paint will start to fail and peel.

- Q: Home decoration decoration in the cement pressure board hanging wire network doing what?

- This is mainly due to the surface of the cement pressure plate is too smooth, the use of barbed wire, you can increase the surface of the putty layer of the structural strength, to prevent wall cracking.

- Q: The scope of application of foam cement

- Pipeline backfill. Underground abandoned oil tanks, pipelines (built-in crude oil, chemicals), sewage pipes and other holes easily lead to fire or landslides, the use of foam concrete backfill can solve these troubles, the cost is also less. The density of foam concrete depends on the diameter of the pipe and the groundwater level, usually 600-1100kg / m? ;.

Send your message to us

Fiber Cement Board for Modular Wall Partition

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords