Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

Waterproofing;Sound Insulation;High density;moisture proof;anti-sunk;Strength;Toughess;Anti wet; Nice thin board usage,bendable.

2,Main Features of the (Cement Boards)

Properties:

·100% Non-asbestos

·Density: 1250 to 1500 kg/m3 (+ - 5%)

·Coefficient of thermal expansion: 0.11 kcal/m.hroC

·Bending Strength: over 180 kgf/cm2

·Linear expansion rate: 0.1%

·Water absorption rate: 35%

·Water penetration rate: 0%

·Water content: 8%

·Incombustibility according to CNS 6532 and BS 476

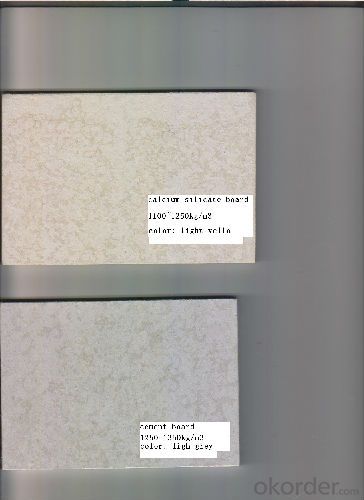

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

5,FAQ of (Cement Boards)

Application

(1)Cavity Wall for Interior Partition

1.Wet area( restroom,kitchen and basement etc.)

2.High sound insulation requirements area ( pc room,meeting room and hotel etc.)

(2) Light Concrete Grouting Wall

(3) Other Applications

1. Ceiling board

2. Perforated board

3. Aluminum lining boards and insulation barriers for high-speed train

4. Column Coverage

Production Scale and Equipment

We introduced international advanced equipment and technologies. From raw materials preparation to board forming stacking and compressing, autoclaving and destacking are all controlled by strict and efficient production craft. The whole process is full automatic, high efficient and quality stable.

- Q: As an artist, I'm experimenting with plaster and cement.As a resident of a temperate zone, I'm wondering about temperature, curing times, and bonding to substrate.I'm working on square pieces of particle board. I rough up the surface with a wire brush to improve bonding to the substrate.Both plaster and cement create heat as they solidify. Are either impaired by a low (and possibly sub-freezing) temperature? I have a makeshift oven that can reach 110 to 120 degrees (F) regardless of the outside temperature. Will heating cement or plaster to this extent improve its ability to bond to wood? Might it only reduce setting time?

- plaster portland cement bonding wood work

- Q: Is the cement board a cement pressure plate? What's the difference?

- Is a kind, just a different name

- Q: how do I drywall over cement in a basement? How do i attach the drywall to the walls?

- You have a couple of options, both similar. Either build a stud wall which will lose you about 3 1/2 of depth or attach firring strips to the wall. You can use 2 x 4s laid flat and attach them to the cement walls with concrete nails, concrete screws (often referred to by a popular brand name such as Tap-Con. I prefer using a powder-activated tool which uses .22 caliber cartridges to drive special nails into the cement. Very fast and you can rent one for about $35/day, nails extra. Put plastic up first, then the 2/4's and nail them flat to the wall. A great time to insulate with 1 1/2 foam board between the boards, which will reduce noise and help to moderate your basement temperature. I'd recommend using green board which is moisture resisitant. I've done this myself and it is a very satisifying improvement.

- Q: in other words: Houses in Mexico are well done.In USA are disposable.

- Pedro, I was visiting some towns in Mexico, From the looks of driving around, even our worst communities are better than what I saw and besides, brick, mud and stone cannot flex during an earthquake vs mostly wood homes in America. That is why during lets say, a 5.8 earthquake might make aunt Martha's favorite disk fall and break but destroy entire buildings in Mexico and other 3rd world nations and hence killing hundreds of people. As far as a cardboard building, cannot help you there; never in my life would I think that a county inspector would pass the required permits needed to build something like that. I wonder if you would even need a fire alarm in one. Are you sure certain you were in America not still in Mexico while trying to jump over the border.

- Q: The floor is on a raised foundation and we were told that there are 2 options: float it on thin set or use a concrete back board. Is there any perference to one over the other? I don't want the tile to crack.

- These answer are old there are at least three different kind of boards you can lay down instead of cement board they are lighter less expensive. Check with your local Lowes or Home depot they carry them and tell you which one is best for what you are laying, there is a big difference from slate and granite and just plain old ceramic tile

- Q: hi, this is my question:To prevent a cement mixer sinking into soft ground, the mixer is placed on a large flat board. Why does this prevent the mixer sinking?the answer will be one of these, which one is it?A The large area decreases the pressure on the ground.B The large area increases the pressure on the ground.C The large area decreases the weight on the ground. D The large area increases the weight on the ground.

- the flat board distributes the weight over a larger area, so the pressure per square inch is reduced.

- Q: I have Joint Compound and cement board tape, How do i fix a 6 inch hole in drywall? Anything else I Need?

- Stuff the hole with balled up newspaper first. Otherwise your tape will not hold well. A better way to fix a hole that large would be to pick up a scrap of drywall, cut the hole square to the center of the studs on either side, attach the patch, and tape and mud the seams. Good luck.

- Q: I need to raise a bathroom floor about 3/4 inch. I have already poured a thin layer of self leveling concrete over what appeared to be some sort of concrete floor that had some uneven areas (60 year old house). I have read about how you are not supposed to put backer board on concrete because you can't secure it. My question is this: could you lay the backer board on top of the SLC, leave some small gaps between the boards, and then pour another layer of SLC on top of the backer board, thereby cementing it into place??

- I'm a tiler and a Hardwood installer. Backer board is specifically used for tile. The board is designed to created a strong and rigid bond to the subfloor. There's always movement in a structure and if you skip backerboard then your tile moves with the natural flexing of the house causing cracking in the tile and grout. Viny is flexible so all you need to do is to remove existing flooring and lay right on the subfloor.

- Q: I use the card light steel keel to do the wall and ceiling, do not want to be fooled, seeking the experience of the people advise

- Ming ceiling generally use U50 or U38 main dragon, vice dragon directly with T-keel instead, hanging pieces hanging on the main keel, and then with the big T1200 * 600 or small T600 * 600 keel, the main material using calcium calcium gypsum board, mineral wool Plate, calcium silicate board; Wall and general steel keel, U75 with C75, high height of the large area with U100, the main material with gypsum board, calcium silicate board, fiber cement board; Do not know can give me a private letter, and the other if the use of aluminum ceilings, pay attention to the requirements of the thickness, check the national standard, 1.2,1.0,0.9,0.8 ... ... different thickness, the price difference is not more than a large part of it

- Q: What is the exterior wall of a light steel structure house?

- Exterior wall paint in accordance with the decorative texture is divided into four categories: 1, thin-walled exterior paint: delicate texture, materials than the province, can also be used for interior decoration, including flat paint, sand-like, mica-like paint. 2, layer pattern paint: pattern was concave and convex, full of three-dimensional sense. 3, color sand paint: with stained quartz sand, porcelain mica powder as the main raw material, color novel, crystal brilliant. 4, thick paint: can be sprayed, can be coated, can roll, can be made of hair, but also to make a different texture pattern.

Send your message to us

Middle Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords