Non-asbestos Waterproof Fireproof Fiber Cement Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

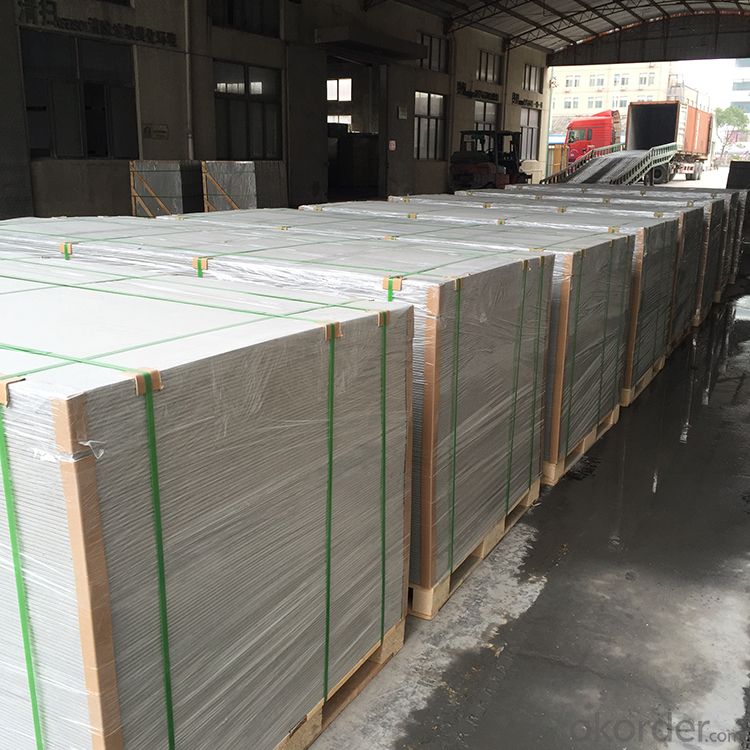

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Fiber cement board is a new architechural and industrial board with cement, quartz, matural and selected minerals as main materials. The board was made through high temperature and high precessure maintenance and other special treatments. It is the first choice for lasting building materials in some developed countries as well as being increasingly applied in more countries.

Specifications

1220x2440x4-20mm, Max width: 1220mm, Max length: 3000mm

Other optional specification available

Optional sanding finishing on the surface

Advantages

1. 100% Asbestos Free

2. Fire Resistance

3. Earthquake Resistance

4. High Strength and Good Stability

5. Inorganic Material and Anti Fungus

6. Good Heat and Sound Insulation

7. Durability and Long Service Life

Typical Applications

Commercial mansion, Industrial building, Hotel, Hospital, Theater, Station, Factory, Warehouse, etc.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

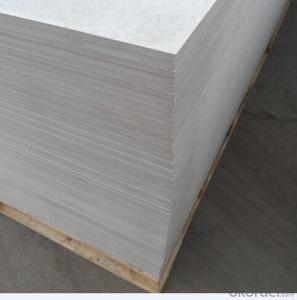

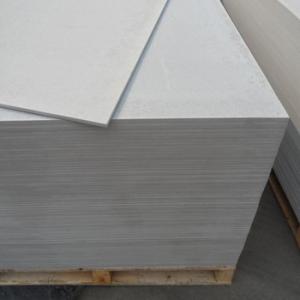

Picture

- Q: how do I drywall over cement in a basement? How do i attach the drywall to the walls?

- You can get concrete nails at the hardware store. Nail 1 x 2 or 1x 4 to the concrete walls then you can apply the sheetrock to the nailers Nail the nailers at 16 on center or 24 on center

- Q: Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Mexichik covered it for the most part, I'd like to add a few things though. If its a light colored tile, back butter the tile too. The trowel marks can show through if you don't. Also, you should seal the tile before you grout at least, but Its recommended to seal it before even installing it. It is a pain but thats why you get more money for installing stone. And be VERY careful, marble scratches so easy.

- Q: My bathroom has a section where there is cement board. Over the cement board is a layer of plaster. Tiles were glued to the plaster. However, the plaster came off of most of the cement board over time. Of course, the tiles have fallen off too. So now I have bare cement board partially covered by plaster.I'd like to remove the remaining plaster from the cement board and then retile directly over the cement board.How to best remove the remaining plaster? Is chipping away at it the only method?

- Use a four inch razor scraper to scrape off the worst of it then use a wet sponge and the rest should wash off easily.Also if you need to you can wet the plaster to help make it easier to scrape.

- Q: Cement fiber board now market price?

- See what you want what manufacturers out of the specifications. I see the same brand, 20 and 15 of the difference between the price of it, 20 of the 41,15 of 27. But also to see where you are, the amount of size, with more words, naturally you can bargain ah!

- Q: I plan on installing about 400 square feet of ceramic tile in a kitchen. I wanted to know if I need to put down a cement backer board before laying the tile?If so, how do I determine if I should use 1/4 inch or 1/2 inch?Finally, what is the preferred method of securing it to the subfloor? Is is it glued somehow or nailed to the floor joists (I suspect nailed, but I've never used it before).The subfloor is plywood and seems secure. I am not sure how thick the plywood is yet (haven't gone to the basement and looked for any stamps on it). I've done ceramic tile before, but it has always been a small area with mosaic tile, so I never put much thought into the backer board.Thanks

- Cement Backer Board

- Q: Hi All,Basically what I am trying to say is that I have a wooden board which will be placed vertically on the floor and would be a decoration.I want to have a coating of cement of some sort on it and make some patterns on it.I like to know if it is possible to lay a thin coating layer of cement or even tile bond glue to a wooden board, lets say a timber board.basically anything that can give me the concrete/cement look as rough as that.. uld be any kind of cement or tiling glue or such...Thanks

- It might crack on you so why don't you just use some modeling clay and use a trowel and just play with it to look like cement

- Q: The cement is in a three foot hole used with lumber for a hammock which, was too small as it broke off at the base. I've read where other people have dug around the cement to loosen it, but my main problem would be lifting it out once it's loose. Another option I found was using a sledge hammer to break it up but I don't own one. I'm sure I could rent one from my local home improvement store, but thought I'd try this avenue first to see if there were any alternatives.Thanks!

- If there is still wood in the concrete use self-starting bolts and bolt another board across so that after loosening dirt around outside of concrete use rope, chain, or whatever to lift out of hole.

- Q: are you able to mountain board not only on dirt but also on surfaces like cement, for ex: a street?

- you probably could

- Q: I use the card light steel keel to do the wall and ceiling, do not want to be fooled, seeking the experience of the people advise

- Ming ceiling generally use U50 or U38 main dragon, vice dragon directly with T-keel instead, hanging pieces hanging on the main keel, and then with the big T1200 * 600 or small T600 * 600 keel, the main material using calcium calcium gypsum board, mineral wool Plate, calcium silicate board; Wall and general steel keel, U75 with C75, high height of the large area with U100, the main material with gypsum board, calcium silicate board, fiber cement board; Do not know can give me a private letter, and the other if the use of aluminum ceilings, pay attention to the requirements of the thickness, check the national standard, 1.2,1.0,0.9,0.8 ... ... different thickness, the price difference is not more than a large part of it

- Q: Is the cement fiber outer wall plate affected by the blisters?

- In particular, the water absorption of the sheet is very important, especially asbestos-free, the density is inversely proportional to the water absorption, the higher the water absorption, the lower the density, the resistance to freezing and thawing and stability The worse, the easier it is to stratify,

Send your message to us

Non-asbestos Waterproof Fireproof Fiber Cement Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords